26

10.1 - Physical data, units with options 5 and 6

Standard-efficiency and high-efficiency 30XW- / 30XWH units (options 5 and 6)

Option 5 (medium temperature)

Option 6 (low temperature)

30XW--/30XWH (reference)

P0512

P0562

P1012

-1154

P0512

P0562

P1012

-1154

Operating weight

kg

2883

2927

6567

5607

2932

2976

6687

5705

Compressors

Semi-hermetic 06T screw compressors, 50 r/s

Circuit A

1

1

1

1

1

1

1

1

Circuit B

-

-

1

1

-

-

1

1

Refrigerant charge

(1)

R-134a

Circuit A

kg

140

140

125

110

140

140

125

110

Circuit B

kg

-

-

135

110

-

-

135

110

Oil charge

SW220

Circuit A

l

32

32

32

32

32

32

32

32

Circuit B

l

-

-

32

32

-

-

32

32

Capacity control

Pro-Dialog, electronic expansion valves (EXV)

Minimum capacity

(2)

%

30

30

20

20

30

30

20

20

Evaporator

Multi-pipe flooded type

Net water volume

l

70

70

204

183

85

85

224

197

Water connections

Victaulic

Inlet/outlet

in

6

6

8

8

5

5

6

6

Drain and vent connections (NPT)

in

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

Maximum water-side operating pressure

kPa

1000

1000

1000

1000

1000

1000

1000

1000

Condenser

Multi-pipe

Net water volume

l

103

103

316

193

103

103

316

193

Water connections

Victaulic

Inlet/outlet

in

6

6

8

8

6

6

8

8

Drain and vent connections (NPT)

in

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

Maximum water-side operating pressure

kPa

1000

1000

1000

1000

1000

1000

1000

1000

(1) Weights are guidelines only. The refrigerant charge is given on the unit nameplate.

(2) Minimum unit capacity corresponds to a physical state of the unit and is given for indication only. The actual capacity at this stage depends on operating conditions.

9.3 - Dimensions and clearances, units with option 150

Please refer to chapter 3.

9.4 - Operating limits, units with option 150

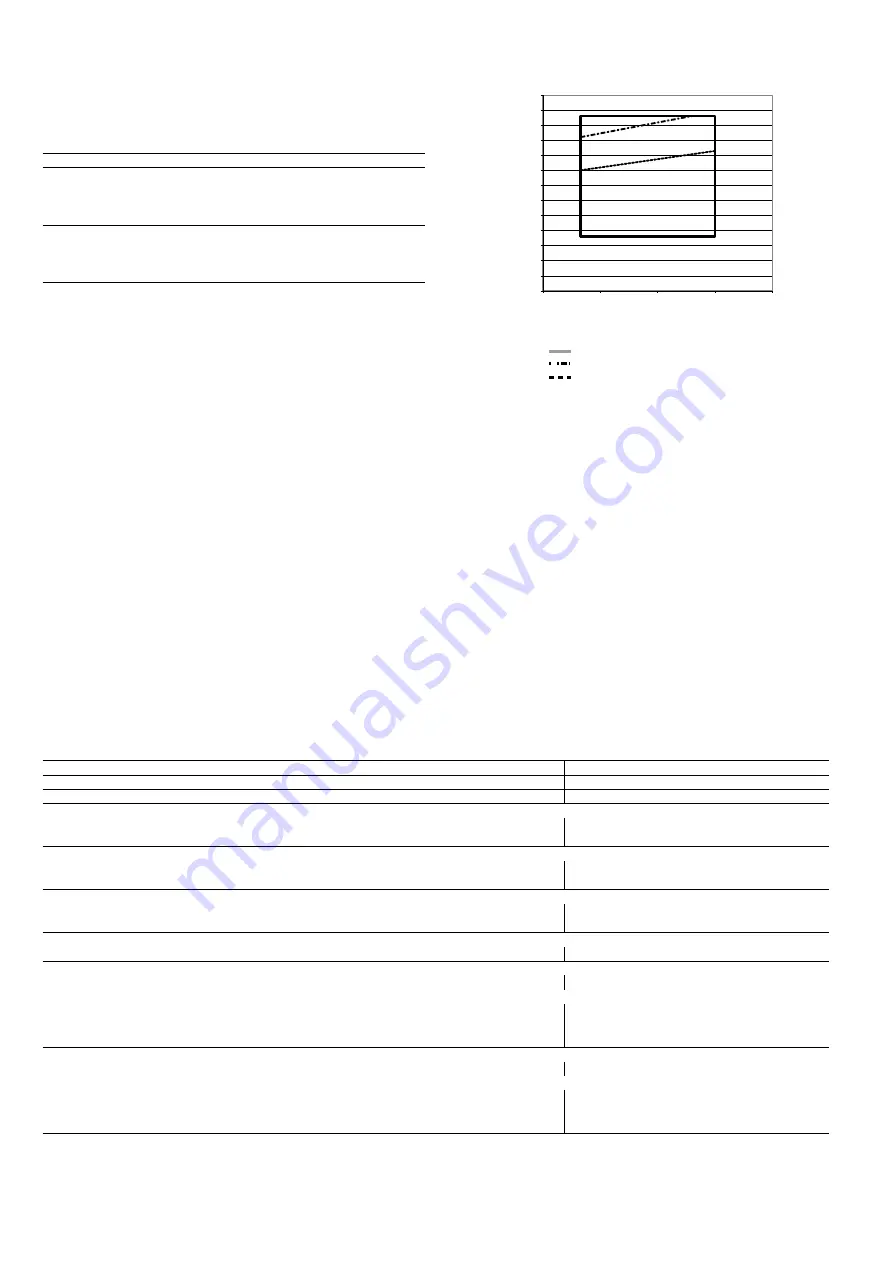

30XW--/30XWH-/30XW-P/30XWHP

Minimum

Maximum

Evaporator

Entering temperature at start-up

-

35.0°C

Leaving temperature during operation

3.3°C

(1)

15.0°C

Entering/leaving temperature difference at full load

2.8 K

11.1 K

Condenser

Entering temperature at start-up

13.0°C

(2)

-

Leaving temperature during operation

23.0°C

(2)

63.0°C

Entering/leaving temperature difference at full load

2.8 K

11.1 K

(1) For low-temperature applications, where the leaving water temperature is

below 3.3°C, a frost protection solution must be used. Please refer to option 5

and option 6.

(2) For lower condenser temperatures a water flow control valve must be used at

the condenser (two or three-way valve). Please refer to option 152 to ensure

the correct condensing temperature.

Note:

Ambient temperatures: During storage and transport of the 30XW units

(including by container) the minimum and maximum permissible temperatures are

-20°C and 72°C (and 65°C for option 200).

Evaporator leaving water temperature, °C

Condenser

lea

ving

w

ater

temper

atur

e,

°C

,

From approx. 60% to full load

Part load limit approx. 50%

Minimum load limit approx.30%

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0

5

10

15

20

Units with the medium temperature (option 5) or low

temperature (option 6) option allow glycol solution

production down to:

•

- 6°C with ethylene glycol and option 5 (minimum

weight concentration of 25%)

•

- 3°C with propylene glycol and option 5 (minimum

weight concentration of 24%)

•

- 12°C with ethylene glycol and option 6 (minimum

weight concentration of 35%)

•

- 8°C with propylene glycol and option 6 (minimum

weight concentration of 30%)

These options are available for the following unit reference

numbers:

30XW- P0512

30XW- P0562

30XW- P1012

30XW--1154

Option 100C (evaporator with one pass) is not compatible

with options 5 and 6. For option 5 the evaporator must be

configured with two passes and for option 6 with three passes.

10 - MEDIUM TEMPERATURE (OPTION 5) AND LOW TEMPERATURE (OPTION 6) GLYCOL SOLUTION OPTIONS

For more precise details refer to the unit selection program.