SG-40MAHB-01: Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

34

APPENDICIES

Appendix 1

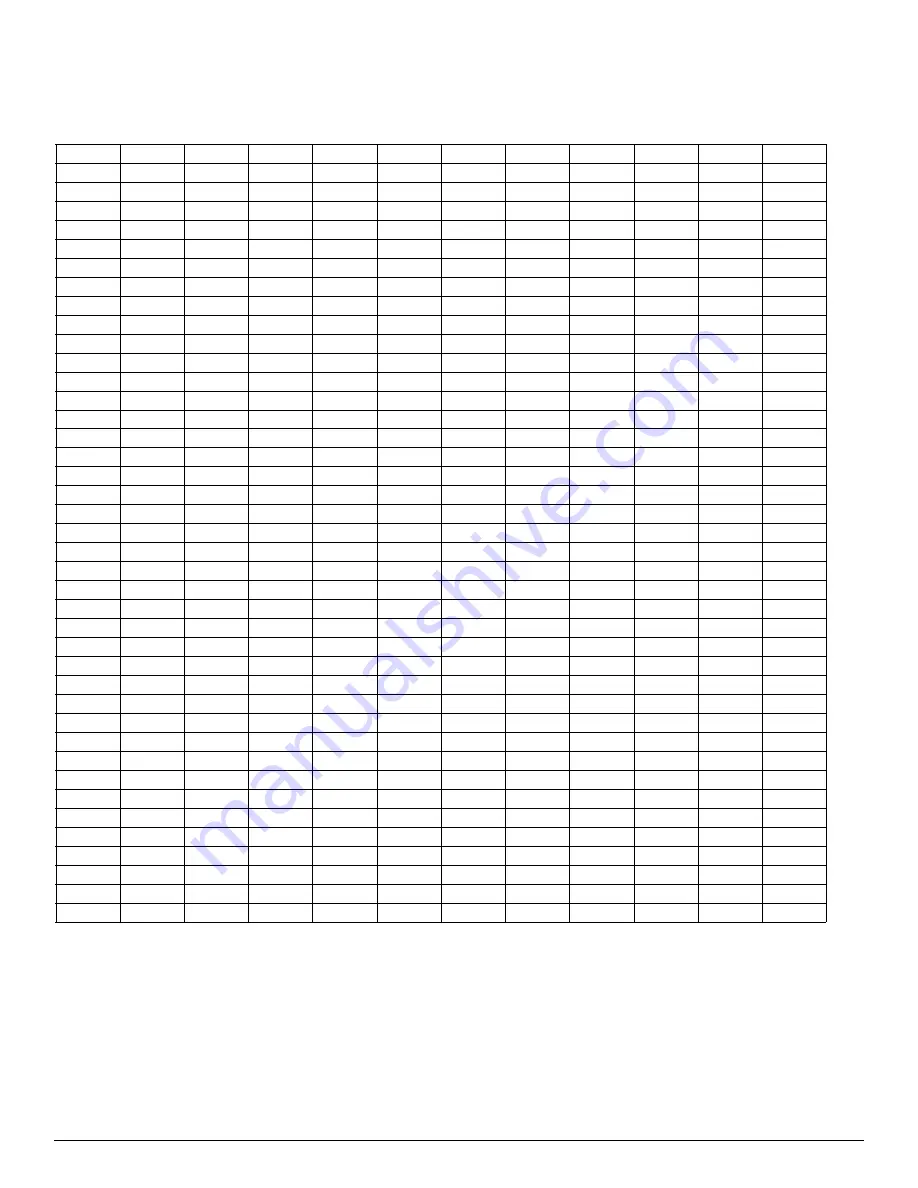

Table 13 — Temperature Sensor Resistance Value Table for T1, T2, T3, T4 (C--K)

°

C

°

F

K Ohm

°

C

°

F

K Ohm

°

C

°

F

K Ohm

°

C

°

F

K Ohm

-20

-4

115.266

20

68

12.6431

60

140

2.35774

100

212

0.62973

-19

-2

108.146

21

70

12.0561

61

142

2.27249

101

214

0.61148

-18

0

101.517

22

72

11.5

62

144

2.19073

102

216

0.59386

-17

1

96.3423

23

73

10.9731

63

145

2.11241

103

217

0.57683

-16

3

89.5865

24

75

10.4736

64

147

2.03732

104

219

0.56038

-15

5

84.219

25

77

10

65

149

1.96532

105

221

0.54448

-14

7

79.311

26

79

9.55074

66

151

1.89627

106

223

0.52912

-13

9

74.536

27

81

9.12445

67

153

1.83003

107

225

0.51426

-12

10

70.1698

28

82

8.71983

68

154

1.76647

108

226

0.49989

-11

12

66.0898

29

84

8.33566

69

156

1.70547

109

228

0.486

-10

14

62.2756

30

86

7.97078

70

158

1.64691

110

230

0.47256

-9

16

58.7079

31

88

7.62411

71

160

1.59068

111

232

0.45957

-8

18

56.3694

32

90

7.29464

72

162

1.53668

112

234

0.44699

-7

19

52.2438

33

91

6.98142

73

163

1.48481

113

235

0.43482

-6

21

49.3161

34

93

6.68355

74

165

1.43498

114

237

0.42304

-5

23

46.5725

35

95

6.40021

75

167

1.38703

115

239

0.41164

-4

25

44

36

97

6.13059

76

169

1.34105

116

241

0.4006

-3

27

41.5878

37

99

5.87359

77

171

1.29078

117

243

0.38991

-2

28

39.8239

38

100

5.62961

78

172

1.25423

118

244

0.37956

-1

30

37.1988

39

102

5.39689

79

174

1.2133

119

246

0.36954

0

32

35.2024

40

104

5.17519

80

176

1.17393

120

248

0.35982

1

34

33.3269

41

106

4.96392

81

178

1.13604

121

250

0.35042

2

36

31.5635

42

108

4.76253

82

180

1.09958

122

252

0.3413

3

37

29.9058

43

109

4.5705

83

181

1.06448

123

253

0.33246

4

39

28.3459

44

111

4.38736

84

183

1.03069

124

255

0.3239

5

41

26.8778

45

113

4.21263

85

185

0.99815

125

257

0.31559

6

43

25.4954

46

115

4.04589

86

187

0.96681

126

259

0.30754

7

45

24.1932

47

117

3.88673

87

189

0.93662

127

261

0.29974

8

46

22.5662

48

118

3.73476

88

190

0.90753

128

262

0.29216

9

48

21.8094

49

120

3.58962

89

192

0.8795

129

264

0.28482

10

50

20.7184

50

122

3.45097

90

194

0.85248

130

266

0.2777

11

52

19.6891

51

124

3.31847

91

196

0.82643

131

268

0.27078

12

54

18.7177

52

126

3.19183

92

198

0.80132

132

270

0.26408

13

55

17.8005

53

127

3.07075

93

199

0.77709

133

271

0.25757

14

57

16.9341

54

129

2.95896

94

201

0.75373

134

273

0.25125

15

59

16.1156

55

131

2.84421

95

203

0.73119

135

275

0.24512

16

61

15.3418

56

133

2.73823

96

205

0.70944

136

277

0.23916

17

63

14.6181

57

135

2.63682

97

207

0.68844

137

279

0.23338

18

64

13.918

58

136

2.53973

98

208

0.66818

138

280

0.22776

19

66

13.2631

59

138

2.44677

99

210

0.64862

139

282

0.22231