3

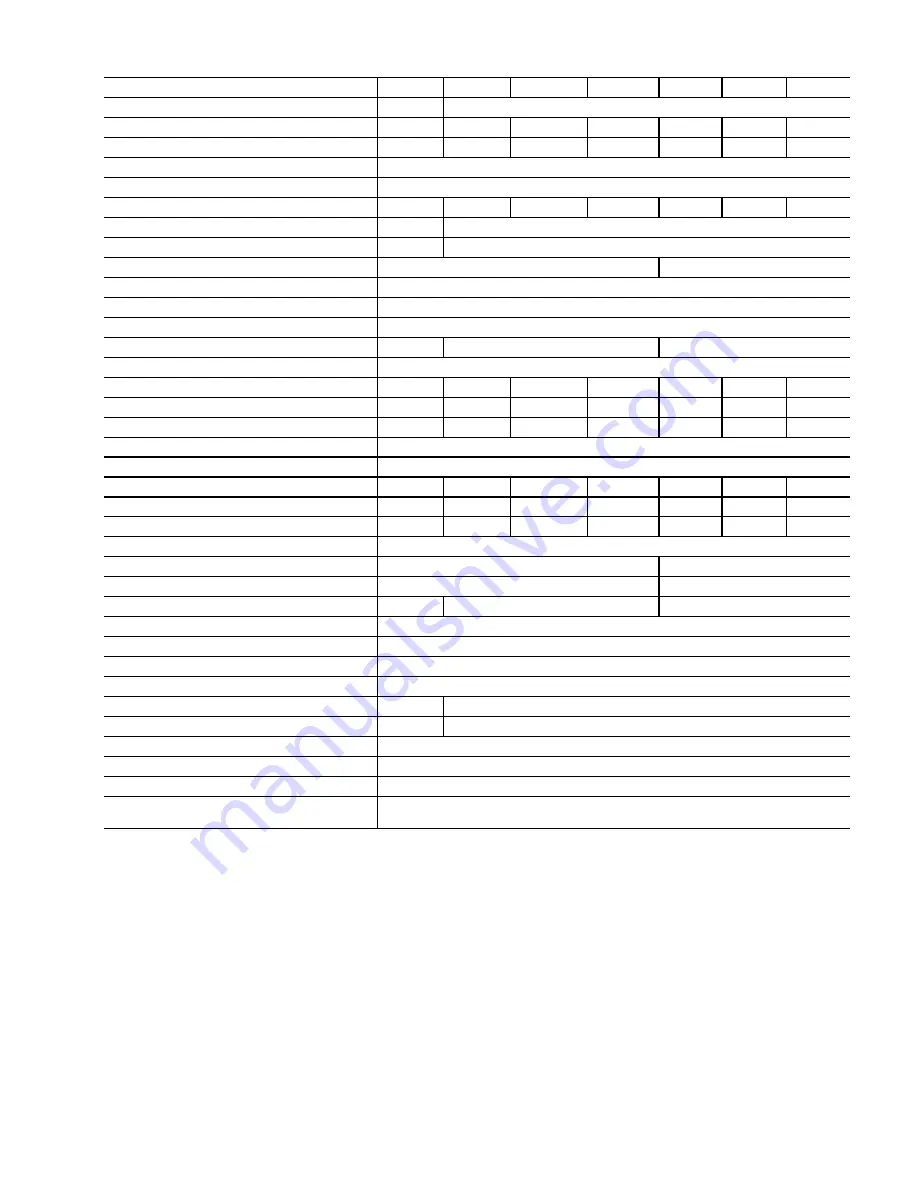

Table 2 —

40VMV Physical Data

LEGEND

American Wire Gage

Electronic Expansion Valve

National Electric Code

*Gross weight includes packaging.

UNIT 40VMV

012

018

024

030

036

048

054

POWER SUPPLY (V-Ph-Hz)

208/230-1-60

COOLING CAPACITY (Btuh)

12,000

18,000

24,000

30,000

36,000

48,000

53,500

HEATING CAPACITY (Btuh)

13,500

21,000

27,000

34,000

40,000

54,000

60,000

INDOOR FAN MOTOR

Type

DC Motor

Input (W)

43

60

100

151

187

355

466

INDOOR COIL

Number of Rows

3

4

Fin Spacing (fins/in.)

16

17

Fin Type

Hydrophilic Aluminum

Tube Diameter, OD (in.)

0.276

Tube Type

Inner Groove

Number of Circuits

6

8

12

INDOOR AIRFLOW (cfm)

Low

320

420

560

700

840

1120

1260

Medium

320

510

680

850

1020

1360

1530

High

400

600

800

1000

1200

1600

1800

EXTERNAL STATIC PRESSURE (in. wg)

0.8

INDOOR UNIT NOISE LEVEL (dBA)

Low

34.5

34.4

37.9

44.4

39.3

43.8

47.9

Medium

34.5

37.1

42.3

48.4

44.1

48.5

52.6

High

37.6

41.6

46.2

52.2

46.9

53.0

57.1

UNIT

Unit Dimensions, W x H x D (in.)

19-5/8 x 46-1/2 x 20-5/8

22 x 54-1/2 x 24

Packing Dimensions, W x H x D (in.)

22-5/8 x 50-5/8 x 25-3/8

24-5/8 x 58-5/8 x 27-3/4

Net/Gross Weight (lb)*

119/143

123/147

163/189

REFRIGERANT TYPE

R-410A

THROTTLE

EEV

DESIGN PRESSURE (psig)

580/320

REFRIGERANT PIPING (in.)

Liquid Side, OD

1/4

3/8

Gas Side, OD

1/2

5/8

CONNECTING WIRING (AWG)

Power Wiring

Sized per NEC and local codes based on nameplate electrical data

Signal Wiring

2-core stranded shielded twisted pair cable 16-20 AWG

CONDENSATE DRAIN PIPE DIAMETER, OD

(in.)

3/4

NPT

AWG

—

EEV

—

NEC

—