5

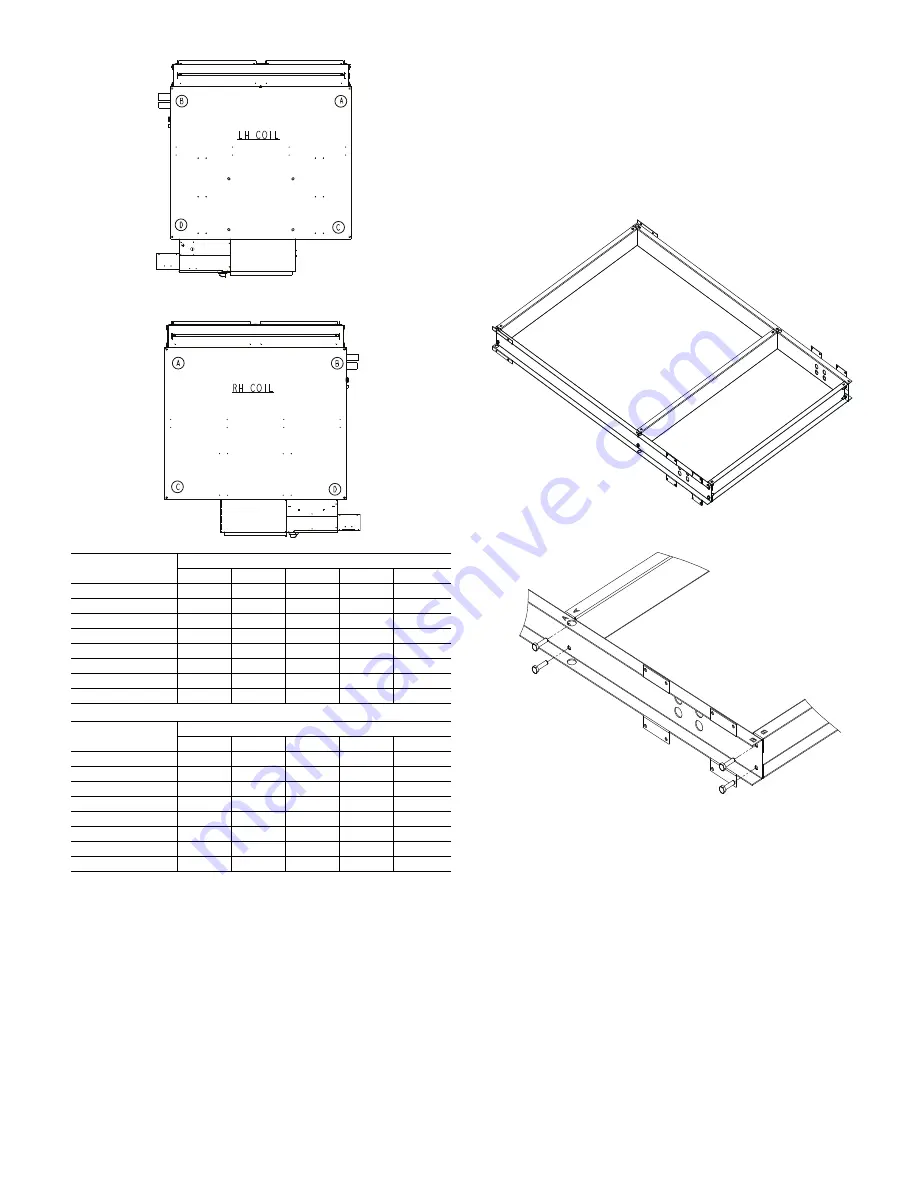

Fig. 5 — Weight Distribution Calculations

Step 2 — Install Mixing Box

1. Mixing boxes are pre-assembled from the factory for ease

of installation. A linkage kit consisting of two crank arms,

2 swivels, and either a 25-in. (sizes 06-16) or a 34-in.

(sizes 20-30) length of

5

/

16

in. rod is provided for field

installation of an actuator.

2. Assemble the base rails (provided with mixing box, see

Fig. 6). All hardware required for assembly is included

and the base rails are letter coded for ease of assembly (as

shown in Fig. 7).

Fig. 6 — Base Rails

Fig. 7 — Letter Coding on Base Rail Parts

3. Place unit on the base rails making sure that the unit is

mounted flush to the outer edge of the end base rail at the

aligning unit mounting holes (as shown in Fig. 8). It may

be necessary to remove factory installed sheet metal

screws to enable access to all mounting holes and to

ensure proper fit. Do not remove screws unless necessary.

Secure unit to base rail using No. 8 x

1

/

2

-in. fasteners at the

locations shown in Fig. 7 and 8, two per side.

42DH UNIT

NO ELECTRIC HEAT (lb)

A

B

C

D

Total

06

42

46

36

47

171

08

41

47

38

45

171

10

51

53

49

63

217

12

50

52

51

64

217

16

65

70

64

75

274

20

78

90

77

95

340

22

83

108

80

99

367

30

103

113

97

117

430

42DH UNIT

WITH ELECTRIC HEAT (lb)

A

B

C

D

Total

06

42

58

36

66

202

08

41

58

36

67

202

10

51

60

56

83

250

12

50

58

57

85

250

16

70

69

66

104

309

20

81

96

77

107

378

22

86

111

81

111

389

30

104

120

96

149

469