-- 33 --

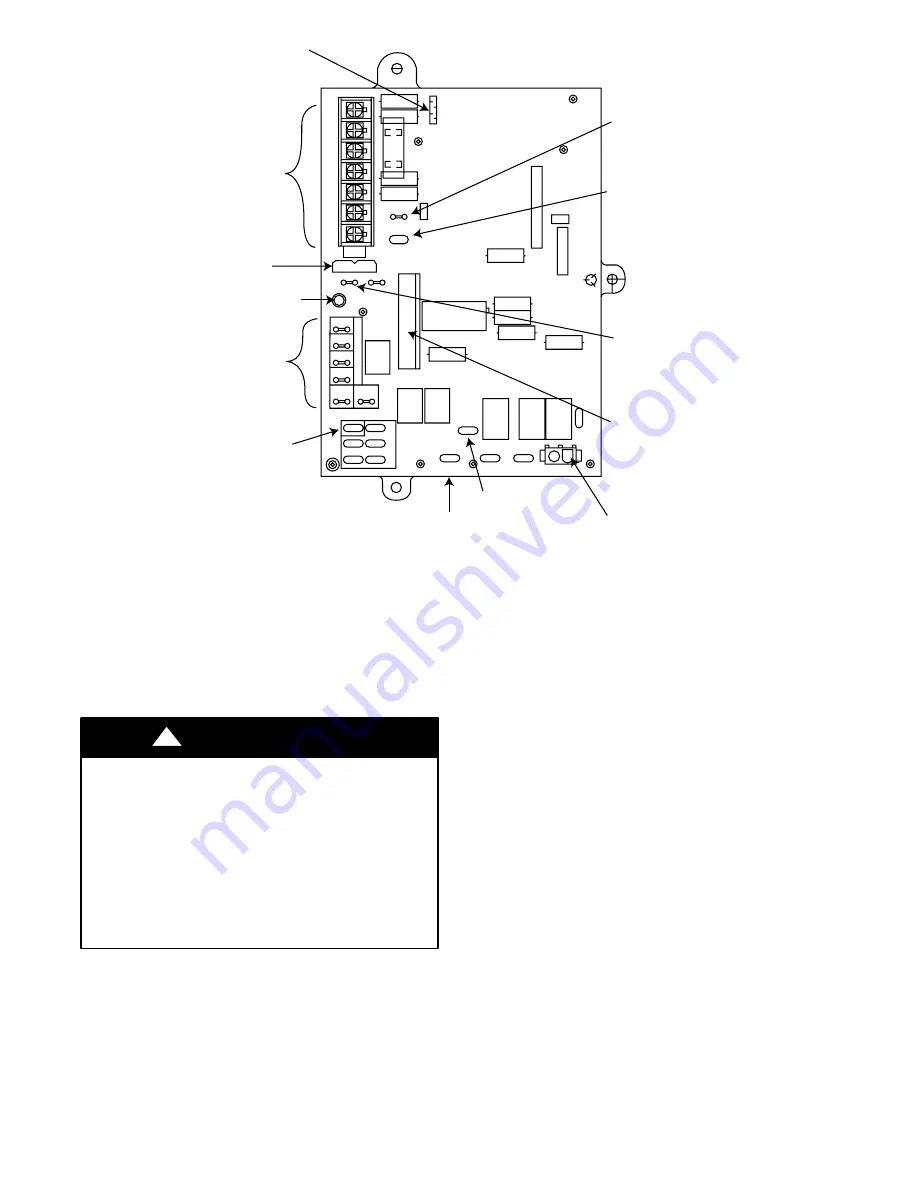

BLOWER OFF-DELAY

T1 DHUM G COM W TIT2 R

24V

TEST / TWIN

HUH

PL

T

SEC-2

SEC-1

COM

24VAC

PL1

24V HTR T

APS

COM

HEAT

COOL

FAN

SPARE 2 SPARE 1

EAC-2

EAC-1

L1

BL-1

PR-1

PL2

BLOWER OFF-DELAY

24-V THERMOSTAT

TERMINALS

3-AMP FUSE

LED OPERATION

& DIAGNOSTIC LIGHT

BLOWER SPEED

SELECTION

TERMINALS

115-VAC (L2)

NEUTRAL

CONNECTIONS

115-VAC (LI)

NUETRAL

CONNECTIONS

EAC-1 TERMINAL

(115-VAC 1.0 AMP. MAX0

PL1-HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTION

PL1-LOW VOLTAGE

DRAIN HARNESS

CONNECTOR

TRANSFORMER

24-VAC CONNECTIONS

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP. MAX)

TWINNING AND/OR

COMPONENT TEST

TERMINAL

A08345

Fig. 36 -- Furnace Control

For Non-Direct Vent (1-Pipe) system, combustion-air must

terminate outside of furnace casing with 1 elbow. Orient elbow so

that its opening faces down for upflow or downflow applications.

Orient elbow so that its opening faces sideways (left or right) for

horizontal left or horizontal right applications (See Fig. 37.)

Maintain a 3-in minimum clearance between the opening of the

combustion-air inlet pipe and any object.

UNIT CORROSION HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Combustion air must not be taken from inside structure

because inside air is frequently contaminated by halogens,

which include fluorides, chlorides, bromides, and iodides.

These elements are found in aerosols, detergents, bleaches,

cleaning solvents, salts, air fresheners, adhesives, paint, and

other household products. Locate combustion-air inlet as far as

possible from swimming pool and swimming pool

pump house.

CAUTION

!

NOTE

: All pipe joints must be cemented, with the exception of

combustion--air pipe to inlet housing connection, as it may be

necessary to remove pipe for servicing.

Assembly of Combustion Air Pipe (Non-Direct Vent/1-Pipe

System ONLY)

1. Permanently

install

perforated

disk

assembly

(factory-supplied in loose parts bag) in combustion-air

elbow using RTV or by cementing, as shown in Fig. 38.

For proper combustion disk usage, please refer to Table

11.

2. Determine the length of straight portion of combustion-air

inlet pipe from Fig. 38.

3. Cut field-supplied 2-in. (51 mm) diameter PVC pipe to

length as determined per Fig. 38.

4. Permanently attach elbow/perforated disk assembly to

straight portion of pipe using RTV or by cementing as

shown in Fig. 38.

Assembly of Combustion Air Pipe (Direct Vent-2-Pipe

System ONLY)

1. Using Table 11, individually determine the diameter of the

combustion--air and vent pipe allowed. If different sizes,

pick the larger of the two diameters and use this diameter

for both combustion--air and vent pipes.

2. When installing vent systems of short pipe length, use the

smallest allowable pipe diameter. use of pipe size greater

than required may result in incomplete combustion, flame

disturbance, and flame sense lockout.