-- 56 --

e. Replace gas valve regulator adjustment screw seal cap.

f. Replace burner enclosure front and verify adjusted gas

input rate using method outlined in Item 3.

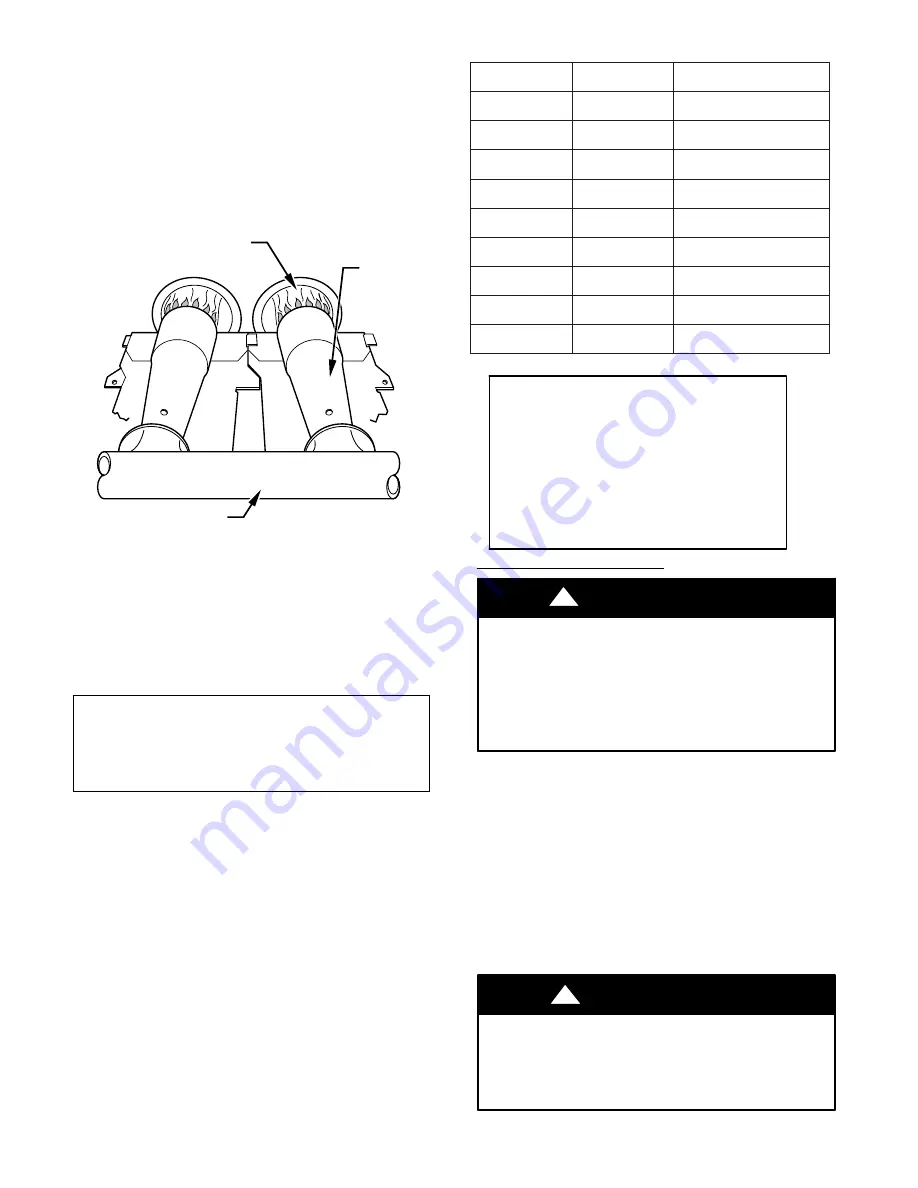

g. Look through sight glass in burner enclosure and

check burner flame. Burner flame should be clear blue,

almost transparent. (See Fig. 57.)

h. Remove jumper from R and W.

3. Verify natural gas input rate by clocking gas meter.

NOTE

:

Be sure all pressure tubing, combustion-air and vent

pipes, and burner box cover front are in place when checking

input by clocking gas meter.

;;

;;

BURNER FLAME

BURNER

MANIFOLD

A89020

Fig. 57 -- Burner Flame

a. Calculate high-altitude adjustment (if required)

UNITED STATES

At altitudes above 2000 ft (609.6 M), this furnace has

been approved for a 2 percent derate for each 1000 ft

(304.8 M) above sea level. See Table 14 for derate

multiplier factor.

EXAMPLE:

100,000 Btuh input furnace installed at 4300 ft.

Furnace Input

Rate

X

Derate

Multiplier

=

Furnace Input

Rate at Installation

at Sea Level

Factor

Altitude

100,000

X

0.91

=

91,000

CANADA

At installation altitudes between 2001 to 4500 ft (609.9

to 1371.6 M), this furnace must be derated 5 percent by

an authorized Gas Conversion Station or Dealer. To

determine correct input rate for altitude, see example

above and use 0.95 as derate multiplier factor.

b. Reinstall burner box cover.

c. Gas valve regulator seal cap MUST be on.

d. Turn off all other gas applications and pilots.

e. Start furnace and let operate for 3 minutes.

f. Measure time (in sec) for gas meter to dial to complete

1 revolution.

g. Refer to Table 15 for cu ft of gas per hr.

h. Multiply gas rate (cu ft/hr) X heating value (Btu/cu ft)

using natural gas heating value from local gas

utility/supplier.

Table 14 –

Altitude Derate Multiplier for U.S.A.

ALTITUDE

FT (M)

PERCENT OF

DERATE

DERATE MULTIPLIER

FACTOR*

0–2000

(305---610)

0

1.00

2001–3000

(610---914)

4---6

0.95

3001–4000

(914---1219)

6---8

0.93

4001–5000

(1219---1524)

8---10

0.91

5001–6000

1524---1829)

10---12

0.89

6001–7000

(1829---2134)

12---14

0.87

7001–8000

2134---2438)

14---16

0.85

8001–9000

2438---2743

16---18

0.83

9001–10,000

2743---3048

18---20

0.81

* Derate multiplier factors are based on midpoint altitude for altitude range.

EXAMPLE: (0-2000 ft (0--610 M) altitude)

Furnace input from rating plate is 100,000 Btuh.

Btu heating input = Btu/cu ft X cu ft/hr

Heating value of gas = 975 Btu/cu ft

Time for 1 revolution of 2-cu ft dial = 70 sec

Gas rate = 103 cu ft/hr (from Table 16)

Btu heating input = 103 X 975 = 100,425 Btuh.

In this example, the orifice size and manifold

pressure adjustment is within

±

2 percent of the

furnace input rate.

SET TEMPERATURE RISE

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component

damage.

Temperature rise must be within limits specified on furnace

rating plate. Recommended operation is at midpoint of rise

range or slightly above.

CAUTION

!

Determine and adjust air temperature rise as follows:

1. Place thermometers in return and supply ducts as close to

furnace as possible. Be sure thermometers do not see heat

exchangers so that radiant heat does not affect readings.

This

practice

is

particularly

important

with

straight-run ducts.

2. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine air

temperature rise.

3. Adjust temperature rise by adjusting blower speed.

Increase blower speed to reduce temperature rise.

Decrease blower speed to increase temperature rise.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect 115-v electrical power before changing speed tap.

!

WARNING