The furnace should be located as close as possible to chimney or

vent in order to keep vent connections short and direct. The

furnace should also be located as near as possible to center of air

distribution system.

Step 2—Location Relative to Cooling Equipment

When installing furnace with cooling equipment for year-round

operation, the following recommendations must be followed for

series or parallel airflow:

1. In series airflow applications, coil is mounted after furnace in

an enclosure in supply-air stream. The furnace blower is used

for both heating and cooling airflow.

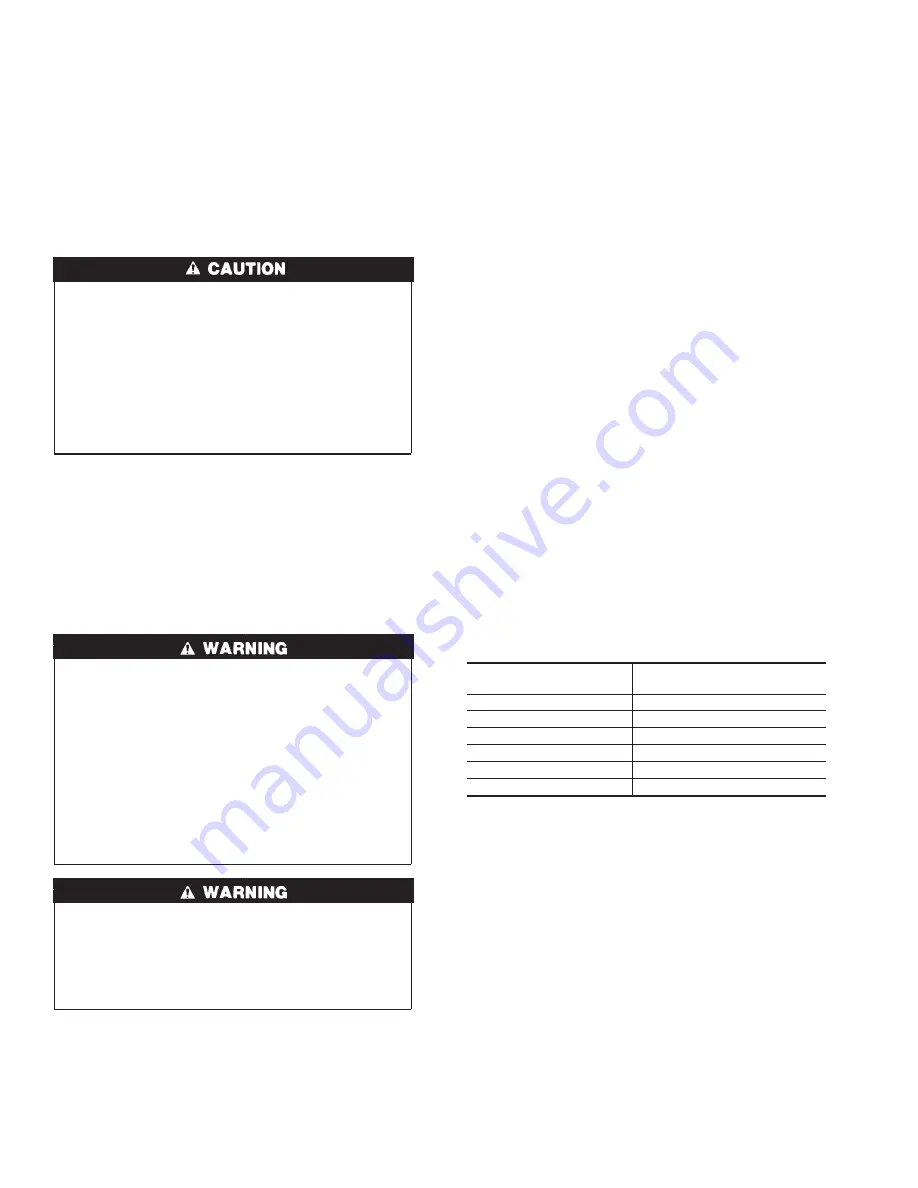

UNIT DAMAGE HAZARD

Failure to follow this caution may reduce the life of this unit.

The coil MUST be installed on air discharge side of furnace.

Under no circumstances should airflow be such that cooled,

conditioned air can pass over furnace heat exchanger. This

will cause condensation in heat exchanger and possible

failure of heat exchanger which could lead to a fire hazard

and/or a hazardous condition which may lead to bodily harm.

Heat exchanger failure due to improper installation may not

be covered by warranty.

2. In parallel airflow applications, dampers must be provided to

direct air over furnace heat exchanger when heat is desired and

over cooling coil when cooling is desired.

IMPORTANT:

The dampers should be adequate to prevent cooled

air from entering furnace. If manually operated, dampers must be

equipped with a means to prevent operation of either cooling unit

or furnace unless damper is in full cool or heat position.

INSTALLATION

Step 1—Air for Combustion and Ventilation

CARBON MONOXIDE POISONING AND UNIT

CORROSION HAZARD

Failure to follow this warning could lead to premature rusting

of heat exchanger and possible premature furnace failure

and/or vent failure which could result in fire hazard and/or

personal injury or death.

Installation of this furnace in an area where it will receive

contaminated combustion air must be avoided. Such contami-

nation would include the following: ammonia, chlorine,

hydrogen sulfide, halogenated hydrocarbons, carbon tetra-

chloride, cleaning solvents, hydrochloric acid, water soften-

ing chemicals, and similar chemicals.

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow this warning could result in property

damage, personal injury or death.

Do not block combustion-air openings in the furnace. Any

blockage could result in improper combustion.

Step 2—General

This furnace should be installed in a location in which facilities for

ventilation permit satisfactory combustion of oil, proper venting,

and maintenance of ambient temperature at safe limits under

normal conditions of use. The location should not interfere with

proper circulation of air within the confined space. (See NFPA-31,

Section 1.5.)

In addition to air needed for combustion, process air shall be

provided as required for: cooling of equipment or material,

controlling dew point, heating, drying, oxidation or dilution, safety

exhaust, and odor control.

In addition to air needed for combustion, air shall be supplied for

ventilation, including all air required for comfort and proper

working conditions for personnel.

The barometric draft regulator (included with furnace) shall be

installed in same room or enclosure as furnace in such a manner as

to prevent any difference in pressure between regulator and

combustion-air supply.

Air requirements for operation of exhaust fans, kitchen ventilation

systems, clothes dryers, and fireplaces shall be considered in

determining the adequacy of a space to provide combustion-air

requirements.

The lack of a proper amount of combustion air can lead to serious

furnace operational problems. Some of these problems are:

1. Excessive oil burner after drip and oil fumes.

2. Sooting.

3. Melted igniter/relay control.

4. Air band or air turbulator settings more open than normal.

5. Lockouts on start-up.

The requirements for combustion and ventilation air depend upon

whether the furnace is located in a CONFINED or UNCONFINED

space.

UNCONFINED SPACE

An unconfined space must have at least 50 cu ft for each 1000

Btuh of total input for all the appliances (such as furnaces, clothes

dryers, water heaters, etc.) in the space. (Refer to Table 2.)

In unconfined spaces in buildings of conventional frame, brick, or

stone construction, infiltration MAY be adequate to provide air for

combustion, ventilation, and dilution of flue gases. This determi-

nation must be made on an individual installation basis and must

take into consideration the overall volume of unconfined space, the

number of windows and ventilation openings, the number of doors

to the outside, internal doors which can close off unconfined space,

and overall tightness of building construction. Consideration must

also be given to the amount of storage items (furniture, boxes, etc.)

within the unconfined space which take away from the air volume.

Many new buildings and homes (and older ones that have been

weatherized) MUST BE considered as being of tight construction,

therefore, infiltration will not be sufficient to supply necessary air

for combustion and ventilation.

A building can be considered as being of tight construction when:

1. Walls and ceilings exposed to outside atmosphere have a

continuous water vapor retarder with a rating of 1 perm or less

with openings gasketed or sealed, and/or

Table 2—Minimum Floor Area for Unconfined

Space

58VLR FURNACE

INPUT BTUH

MINIMUM SQ FT WITH

7-1/2 FT CEILING

70,000

467

91,000

607

105,000

700

119,000

793

140,000

933

154,000

1028

4

→