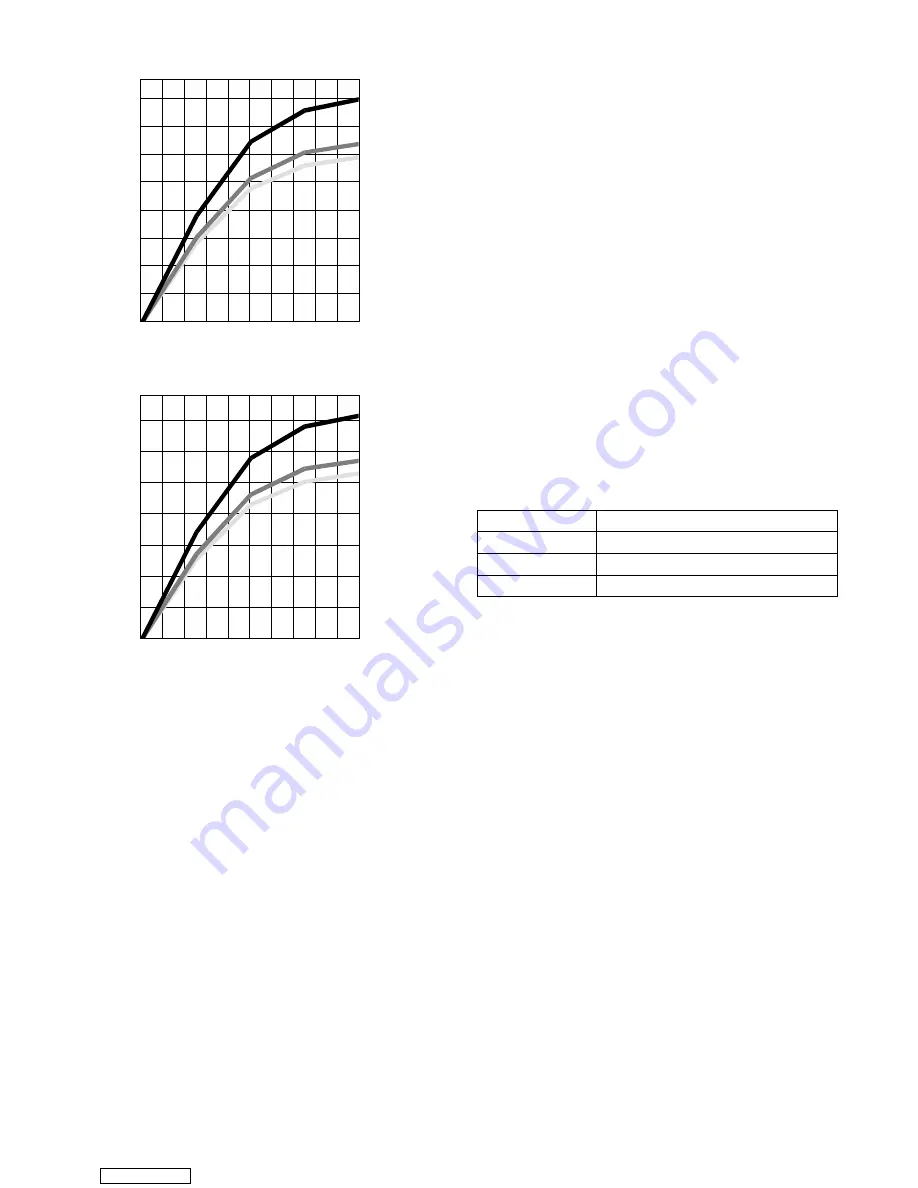

T-296

4-2

0

30

60

90

120

150

180

210

240

0 10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

50HZ

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

0

40

80

120

160

200

240

280

0 10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

60HZ

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

Figure 4-2 Make Up Air Flow Chart 50/60Hz

4.4 CONNECT WATER-COOLED CONDENSER

The water-cooled condenser is used when cooling

water is available and heating the surrounding air is

objectionable, such as in a ship’s hold. If water cooled

operation is desired, connect in accordance with the

following subparagraphs.

4.4.1 Water--Cooled Condenser with Water Pres-

sure Switch

a. Connect the water supply line to the inlet side of con-

denser and the discharge line to the outlet side of the

condenser. (See Figure 2-5.)

b. Maintain a flow rate of 11 to 26 liters per minute (3 to 7

gallons per minute). The water pressure switch will

open to de-energize the condenser fan relay. The

condenser fan motor will stop and will remain stopped

until the water pressure switch closes.

c. To shift to air-cooled condenser operation,disconnect

the water supply and the discharge line to the water-

cooled condenser. The refrigeration unit will shift to

air-cooled condenser operation when the water pres-

sure switch closes.

4.4.2 Water-Cooled Condenser with Condenser

Fan Switch

a. Connect the water supply line to the inlet side of con-

denser and the discharge line to the outlet side of the

condenser. (See Figure 2-5.)

b. Maintain a flow rate of 11 to 26 lpm (3 to 7 gpm).

c. Set the condenser fan switch to position ”O”. This will

de-energize the condenser fan relay. The condenser

fan motor will stop and remain stopped until the CFS

switch is set to position ”I.”

CAUTION

When condenser water flow is below 11 lpm

(3 gpm) or when water-cooled operation is

not in use, the CFS switch MUST be set to

position ”1” or the unit will not operate

properly.

d. To shift to air-cooled condenser operation, stop the

unit, set the CFS switch to position ”I” and restart the

unit. Disconnect the water lines to the water-cooled

condenser.

4.5 CONNECT REMOTE MONITORING

RECEPTACLE

If remote monitoring is required, connect remote

monitor plug at unit receptacle. (See item 9, Figure 2-6.)

When the remote monitor plug is connected to the

remote monitoring receptacle, the following remote

circuits are energized:

CIRCUIT

FUNCTION

Sockets B to A Energizes remote cool light

Sockets C to A Energizes remote defrost light

Sockets D to A Energizes remote in-range light

4.6 STARTING AND STOPPING INSTRUCTIONS

WARNING

Make sure that the unit circuit breaker(s)

(CB-1 & CB-2) and the START-STOP switch

(ST) are in the “O” (OFF) position before

connecting to any electrical power source.

4.6.1 Starting the Unit

1. With power properly applied, the fresh air damper set

and (if required) the water cooled condenser con-

nected, (refer to paragraphs 4.2, 4.3 & 4.4) place the

START-STOP switch to “I” (ON).

2. Continue with Start Up Inspection, paragraph 4.7.

4.6.2 Stopping the Unit

To stop the unit, place the START-STOP switch in

position “0” (OFF).

4.7 START--UP INSPECTION

4.7.1 Physical Inspection

a. Check rotation of condenser and evaporator fans.

b. Check compressor oil level. (Refer to paragraph

6.8.6.)

4.7.2 Check Controller Function Codes

Check and, if required, reset controller Function Codes

(Cd27 through Cd39) in accordance with desired

operating parameters. Refer to paragraph 3.2.2.

4.7.3 Start Temperature Recorder

Downloaded from