6-18

T-296

the suction gauge. Within one minute the suction

pressure will go into a vacuum. This is an indication

that the valve is moving.

4. If no change in suction pressure is detected, check

for resistance (refer to step 6.18.2), and check con-

nections for proper continuity and retest. If the valve

is functioning and all connections and motor resist-

ance are good, check the drive module. (Refer to

step 6.18.3)

5. If the valve is determined as faulty after completing

the above steps, perform a low side pump down. Re-

move valve powerhead assembly, and replace with a

NEW valve powerhead assembly, torque nut to 35 ft-

lb, evacuate low side, and open all service valves.

CAUTION

DO NOT disassemble piston from NEW suc-

tion modulating valve powerhead assem-

bly. Doing so may result in damage to pis-

ton.

6.18.3 Checking The Drive Module

a. Turn unit OFF.

b. Disconnect the four pin connector to the SMV.

c. With voltmeter set to read 24 volts AC, attach the pos-

itive lead to the drive module outlet pin “A” (wire 1A) of

the four pin connector and the negative lead to the “B”

pin (wire 1B).

d. Turn ON unit, and watch the volt meter. After a short

delay, the reading should rise to approximately 12

volts.

e. Repeat for pins “C” and “D” (wires 2 A and 2 B).

f. If only one set of pins reads a voltage, check connec-

tions and retest.

g. If the retest reads out the same, the drive module or

controller is faulty.

h. If no voltage is present in any step, the output from the

controller to the drive module may be faulty, and will

require checking the connections and wires from the

controller to the drive module. Refer to step 6.18.4

i. To replace the drive module, disconnect all connec-

tors, unscrew from mounting, and replace with a

NEW drive module in reverse order.

6.18.4 Checking The Controller

a.

Turn the unit OFF.

b. Disconnect the six pin connector to the stepper drive

from the controller.

c. With the voltmeter set to read 50 volts DC, attach the

positive lead to outlet pin “A” of the six pin connector,

and the negative lead to pin “B” or TP-9 of the con-

troller.

d. Turn ON the unit for 40 seconds, and watch the volt-

meter. There should be approximately 24 to 32 VDC

shown on pin “A”.

e. There should be zero volts on pin “B”.

f. After a short delay, the reading should rise to approx-

imately 24 to 32 VDC on pin “E”.

g. Pins “C” and “D” will have zero to 5 volts transistor

logic (TTL) signals present, however, this can only

be checked with the connector assembled as this is

an open collector type circuit.

By checking the outputs on “A,” “B,” and “E” it can be

verified that the controller is supplying power to the drive

module. To be thorough, and if it is desired, the signals

on pins “C” and “D” can be checked as follows:

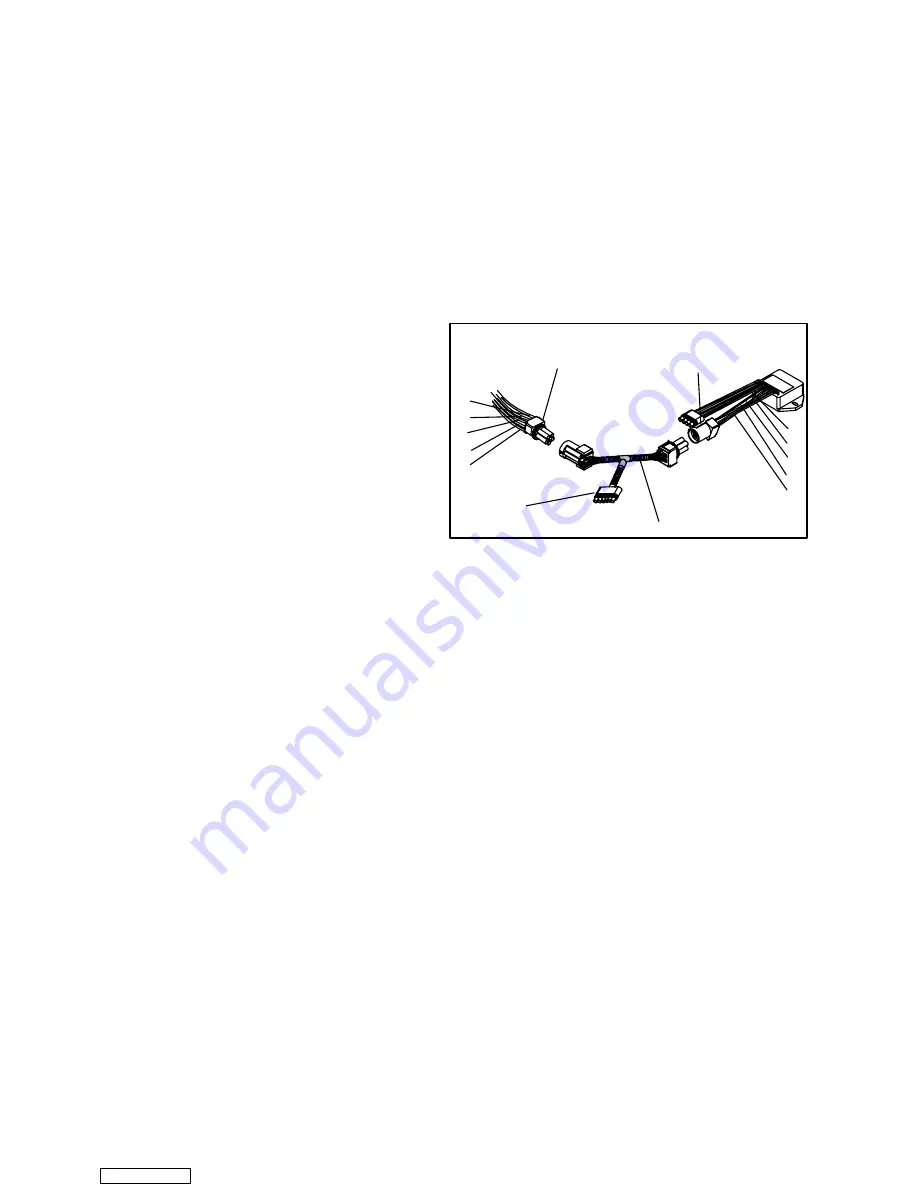

1. Install a jumper assembly (Carrier part number

07--00408--00) to connect the drive module and con-

troller connectors as shown in Figure Figure 6-25.

2. Connect the positive lead of the voltmeter to test

connector socket “C” and negative lead to socket

“B,” and run as before by resetting unit.

3. Repeat for sockets “D” and “B.”

A

B

C

D

E

A

B

C

D

E

Controller

Connector (EC)

Drive Module

Connector (SD)

Jumper

Test

Connector

Figure 6-25 Jumper Assembly

There should be approximately five volts DC on sockets

“C” and “D” (S1 and S2) when measured as above. If not

the connections or controller is faulty.

If any of these pins are not consistent, the connections

or controller is suspect. Check and replace as required.

6.18.5 Emergency Repair Procedures:

In the event that the SMV system has a failure and

replacement components are not readily available the

system can be by--passed by removing the valve piston.

to remove the piston, do the following:

a. Perform a low side pump down. Refer to paragraph

6.4.

b. Remove SMV powerhead by loosening the 2-1/8

inch diameter nut (see Figure 6-24) to relieve any

pressure and then , sliding the powerhead out.

c. Remove the piston by loosening the Allen screw and

removing the piston and screw.

d. Install the powerhead assembly (without the piston),

torque to 35 to 40 foot-lbs.

e. Open all valves.

f. Start the unit.

g. Adjust the suction service valve so that the approxi-

mate temperature OR current limit is maintained.

For perishable loads, it is recommended that the ad-

justment be made so that the available capacity is

slightly larger than the load, the unit will cycle OFF

and ON.

h. Once repair parts become available, repair as re-

quired.

Downloaded from