6--11

T-334

Summary of Procedure:

a. Drain water from condenser tubing circuit. Clean

water tubes with Oakite No. 22 to remove mud and

slime.

b. Flush.

c. De-scale water tubes with Oakite No. 32 to remove

scale.

d. Flush.

e. Neutralize.

f. Flush.

g. Put unit back in service under normal load and check

head (discharge) pressure.

Detailed Procedure:

1. Drain and flush the water circuit of the condenser

coil. If scale on the tube inner surfaces is accompa-

nied by slime, a thorough cleaning is necessary

before de-scaling process can be accomplished.

2. To remove slime or mud, use Oakite Composition

No. 22. Mixed 170 grams (6 ounces) per 3.785 liters

(1 U.S. gallon) of water. Warm this solution and circu-

late through the tubes until all slime and mud has

been removed.

3. After cleaning, flush tubes thoroughly with fresh

clean water.

4. Prepare a 15% by volume solution for de-scaling, by

diluting Oakite Compound No. 32 with water. This is

accomplished by slowly adding 0.47 liter (1 U.S. pint)

of the acid (Oakite No. 32) to 2.8 liters (3 U.S. quarts)

of water.

WARNING

Oakite No. 32 is an acid. Be sure that the

acid is slowly added to the water. DO NOT

PUT WATER INTO THE ACID - this will cause

spattering and excessive heat.

WARNING

Wear rubber gloves and wash the solution

from the skin immediately if accidental con-

tact occurs. Do not allow the solution to

splash onto concrete.

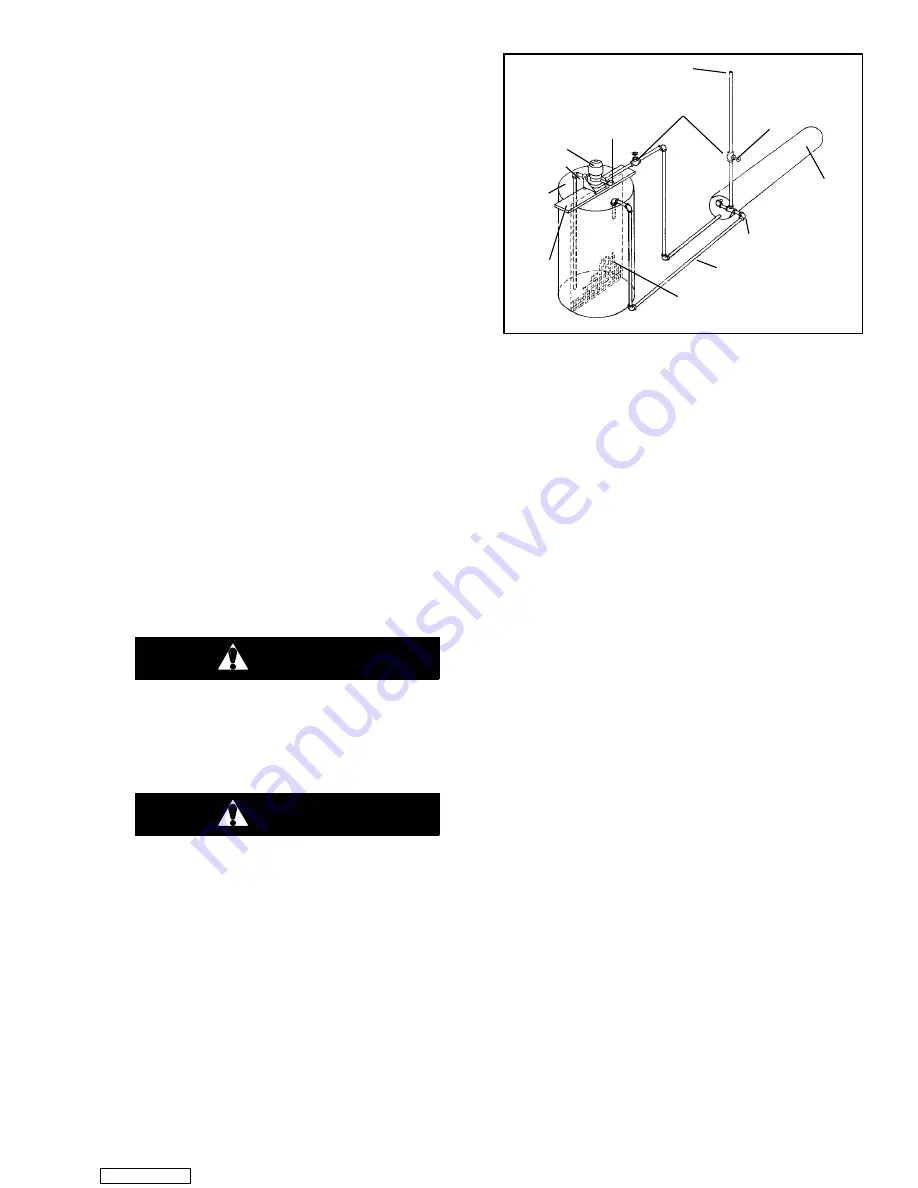

5. Fill the tubes with this solution by filling from the bot-

tom. See Figure 6--9. Important: be sure to provide a

vent at the top for escaping gas.

6

4

3

1

2

12

11

10

7

8

9

5

1. Pump support

2. Tank

3. Suction

4. Pump

5. Priming Connection

(Centrifugal pump

50 gpm at 35’ head)

6. Globe valves

7. Vent

8. Close vent pipe valve

when pump is running

9. Condenser

10. Remove water

regulating valve

11. Return

12. Fine mesh screen

Figure 6--9 Water-Cooled Condenser Cleaning -

Forced Circulation

6. Allow the Oakite No. 32 solution to soak in the tube

coils for several hours, periodically pump-circulating

it with an acid-proof pump.

An alternate method may be used whereby a pail

(see Figure 6--10) filled with the solution and

attached to the coils by a hose can serve the same

purpose by filling and draining. The solution must

contact the scale at every point for thorough de-scal-

ing. Air pockets in the solution should be avoided by

regularly opening the vent to release gas.

Keep

flames away from the vent gases.

7. The time required for de-scaling will vary, depending

upon the extent of the deposits. One way to deter-

mine when de-scaling has been completed is to

titrate the solution periodically, using titrating equip-

ment provided free by the Oakite Technical Service

representative. As scale is being dissolved, titrate

readings will indicate that the Oakite No. 32 solution

is losing strength. When the reading remains

constant for a reasonable time, this is an indication

that scale has been dissolved.

8. When de-scaling is complete, drain the solution and

flush thoroughly with water.

9. Following the water flush, circulate a 56.7 gram

(2 ounce) per 3.785 liter (1 U.S. gallon) solution of

Oakite No. 22 thru the tubes to neutralize. Drain this

solution.

10.Flush the tubes thoroughly with fresh water.

Downloaded from