46

440 01 4801 00

Specifications subject to change without notice.

Representative drawing only, some models may vary in appearance.

TO CODE--APPROVED DRAIN OR CONDENSATE PUMP

Tee

Dry Well

Cap

(water tight

and removable)

Tee

Dry Well

Cap

(water tight

and removable)

Tee

Dry Well

Cap

(water tight

and removable)

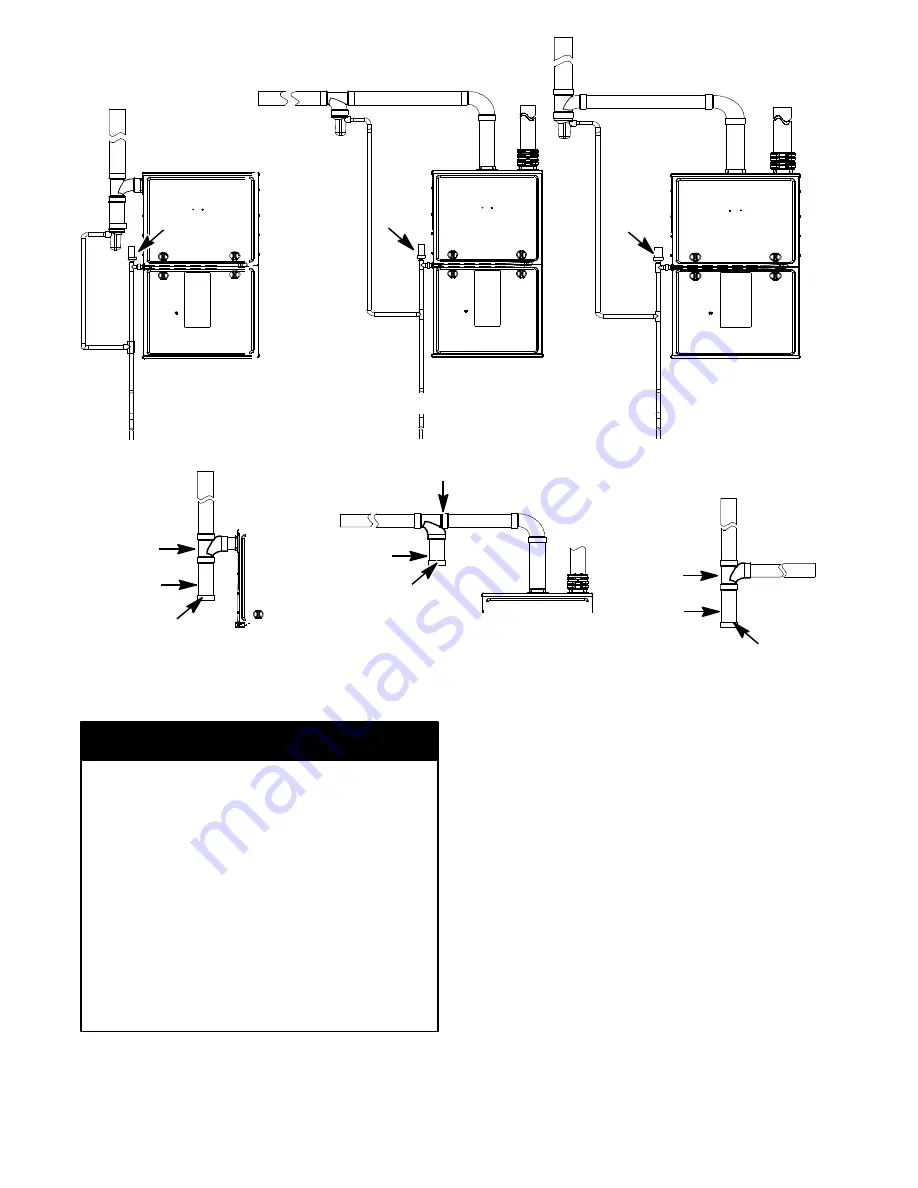

Recommend “T” fitting with 4--inch minimum height standpipe (

A

) of same diameter or larger extending upward.

A

A

A

A170122A

Fig. 51 -- Recommended Combustion Air Inlet Moisture Trap

ADDITIONAL INFORMATION FOR

POLYPROPYLENE VENTING SYSTEMS

Polypropylene venting systems include flexible vent pipe.

These flexible vent pipes have a different equivalent vent

length than straight sections of PVC/ABS DWV vent pipe. Be

sure to make the appropriate deductions from the Maximum

Equivalent Vent Length (MEVL), or additions to the Total

Equivalent Vent Length (TEVL), when applying flexible vent

pipes

in

polypropylene

venting

systems.

See

the

polypropylene vent system manufacturer’s installation

instructions for details.

When using metric-sized venting systems, use these

equivalencies for obtaining the proper MEVL from the Tables:

Use 2” Vent Tables for 60 mm (o.d.) vent systems

Use 3” Vent Tables for 80 mm (o.d.) vent systems

Use 4” Vent Tables for 100 mm (o.d.) vent systems

NOTICE

NOTE

: Polypropylene venting systems MAY require additional

deductions from the MEVL, or additions to the TEVL, for vent

terminations and flexible pipe sections. See the polypropylene

venting system manufacturer’s instructions for details on

equivalent lengths of vent terminations and flexible vent pipes,

and for calculating total vent lengths.

To calculate the Total Equivalent Vent Length (TEVL) of the

venting system:

1. Measure the individual distance from the furnace to the ter-

mination for each pipe.

2. Count the number of elbows for each pipe.

3. For each pipe, multiply the number of elbows by the equiv-

alent length for the type of elbow used. Record the equiva-

lent length of all the elbows for each pipe.

4. If a Tee is used on the termination (Alberta and

Saskatchewan, when required) record the equivalent length

of the Tee used.

5. Calculate Total Equivalent Vent Length by adding the

equivalent lengths of the fittings to the lengths of the indi-

vidual vent and combustion air pipes.

6. When using polypropylene venting systems with flexible

vent pipes, perform adjustments for the equivalent length of

the flexible vent pipe to the calculated total equivalent

venting system length. See the polypropylene vent system

manufacturer’s instructions for details.

7. Select a diameter of vent pipe from Table 13 and note the

Maximum Equivalent Vent Length (MEVL) shown for that

application for that specific furnace input size. Compare the

Total Equivalent Vent Length (TEVL) to the MEVL:

8. If the Total Equivalent Vent Length is

shorter

than the

Maximum Equivalent Vent Length for the diameter of pipe

chosen, then that diameter of pipe selected may be used.