F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

39

The Maximum Vent Length for the vent and combustion air pipe (when

used) is determined from the Maximum Equivalent Vent Length in

minus the number of fittings multiplied by the deduction for

each type of fitting used from

.

A93034

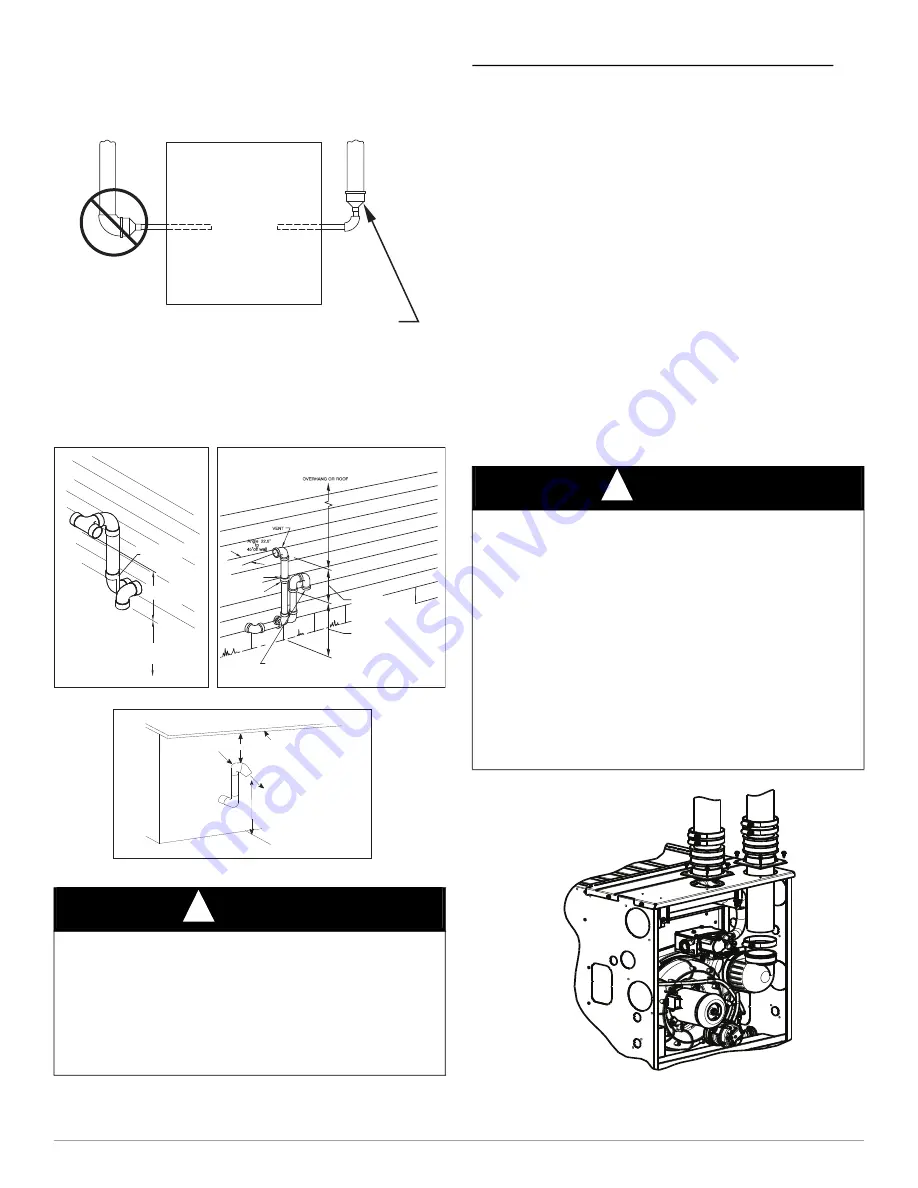

Fig. 46 – Combustion Air and Vent Pipe Diameter Transition

Location and Elbow Configuration

A13078

Fig. 47 – Alberta and Saskatchewan Vent Termination

Recommended Combustion Air Inlet Moisture Trap

To prevent moisture from trickling into the furnace vestibule, a trap can

be installed in the intake air pipe near the furnace. To prevent moisture,

connecting a drain line to the trap is recommended as trace amounts of

moisture will evaporate into the intake air stream. If the combustion air

inlet is located near a moisture exhaust duct, or there are other concerns

of excessive moisture being drawn into the combustion air inlet, it is

encouraged to connect a drain line to the trap.

The trap can be constructed from a running tee of the same diameter of

the intake air pipe with

EITHER

a removable cap attached to a 6-inch

long pipe connected to the tee or the External Vent Trap Kit to help

prevent contaminants from entering the furnace, see

The External Vent Trap Kit accessory may be used as a trap for the

combustion air inlet pipe if a large amount of moisture must be removed.

The drain line may be connected to the same drain as the furnace

condensate and the evaporator coil condensate line

ONLY

if the inlet air

trap drain and the evaporator coil drain empty into an open segment of

. When using the External Vent Trap Kit,

refer to those instructions for proper drain connections.

The tee may also be connected to the intake air pipe on the side of the

.

In any configuration, it will be necessary to add the equivalent length of

the tee (15 feet/5 M) to the Total Equivalent Vent Length of the venting

system.

A12220

Fig. 48 – Sample Inlet Air Pipe Connection for Polypropylene

Venting Systems

NOTICE

!

OPTIONAL CONFIGURATION FOR COMBUSTION

AIR INLET PIPE

In applications where there is a risk of excessive moisture entering the

combustion air inlet pipe, a moisture trap may be added to the inlet pipe

to help prevent moisture from entering the furnace from the combustion

air inlet pipe, see

When sizing venting systems, the equivalent length of the optional

moisture trap (15 feet/5 M) must be taken into account.

FURNACE

PIPE DIAMETER

TRANSITION IN

VERTICAL SECTION

NOT IN

HORIZONTAL

SECTION

OPTIONAL TERMINATION

BRACKET FOR 2-PIPE

TERMINATIONS

12-IN. (305 MM)

ABOVE ANTICIPATED

SNOW LEVEL

12 IN. (305 MM) MIN. SEPARATION

BETWEEN BOTTOM OF

COMBUSTION AIR AND

BOTTOM OF VENT.

MAINTAIN 12 IN. (305 MM)

CLEARANCE ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL OR GRADE,

WHICHEVER IS GREATER.

COMBUSTION-AIR

(ELBOW PARALLEL TO WALL)

OVERHANG

12 IN. (305 MM) MIN. GROUND

LEVEL OR ANTICIPATED SNOW LEVEL

EXHAUST

CLEARANCE TO OVERHANG PER CODE

OPTIONAL

BRACKET

COUPLING

12 IN. (305 MM) MIN.

SEPARATION BETWEEN

BOTTOM OF COMBUSTION

AIR AND BOTTOM OF VENT.

NOTICE

!

ADDITIONAL INFORMATION FOR

POLYPROPYLENE VENTING SYSTEMS

Polypropylene venting systems include flexible vent pipe. These

flexible vent pipes have a different equivalent vent length than straight

sections of PVC/ABS DWV vent pipe. Be sure to make the appropriate

deductions from the Maximum Equivalent Vent Length (MEVL), or

additions to the Total Equivalent Vent Length (TEVL), when applying

flexible vent pipes in polypropylene venting systems. See the

polypropylene vent system manufacturer’s installation instructions for

details.

When using metric-sized venting systems, use these equivalencies for

obtaining the proper MEVL from the Tables:

Use 2” Vent Tables for 60 mm (o.d.) vent systems

Use 3” Vent Tables for 80 mm (o.d.) vent systems

Use 4” Vent Tables for 100 mm (o.d.) vent systems

EXAMPLE FOR

UPFLOW INSTALLATIONS.

MAY BE APPLIED TO

OTHER CONFIGURATIONS.