F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

54

In the USA, the input rating for altitudes above 2000 ft. (609.6M) must

be reduced by 2 percent for each 1000 ft. (304.8M) above sea level.

Refer to

In Canada, the input rating must be reduced by 5 percent for altitudes of

2000 ft. (609.6M) to 4500 ft. (1371.6M) above sea level. The natural gas

manifold pressures in Tables 18 and 19 adjust for BOTH altitude and

natural gas heating value.

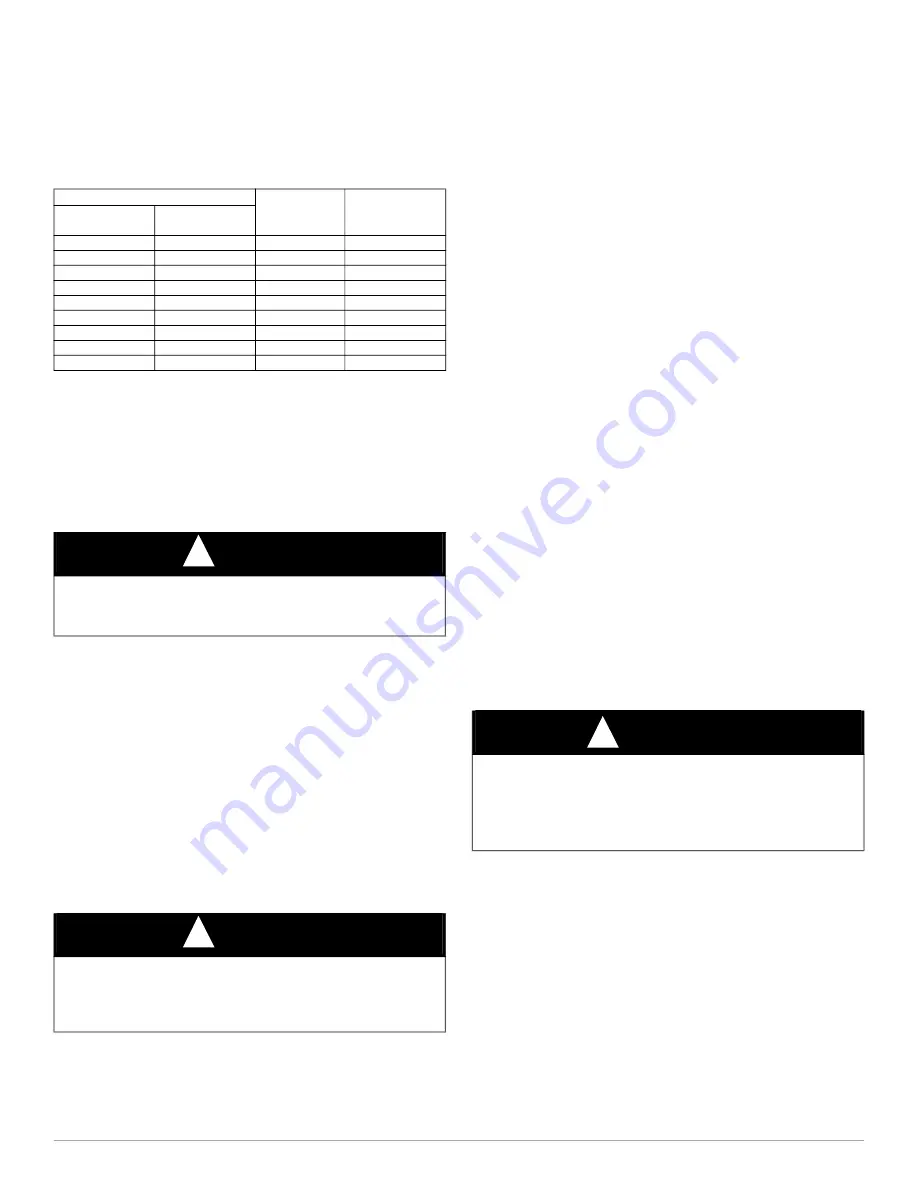

Table 16 – Altitude Derate Multiplier for U.S.A.*

*Derate multiplier factors are based on midpoint altitude for altitude range.

NOTE:

For Canadian altitudes of 2000 to 4500 ft. (610 to 1372 M), use

USA altitudes of 2001 to 2000 ft. (611 to 914 M) in

.

To adjust manifold pressure to obtain the proper input rate, first,

determine if the furnace has the correct orifice installed. At higher

altitudes or different gas heat contents, it may be necessary to change the

factory orifice to a different orifice. Tables have been provided in the

furnace installation instructions to match the required orifice to the

manifold pressure to the heat content and specific gravity of the gas.

To do this:

1. Obtain average yearly gas heat value (at installed altitude) from

local gas supplier.

2. Obtain average yearly specific gravity from local gas supplier.

3. Find installation altitude range for your installation in the manifold

for 20,000 Btuh Max-Heat/8,000 Btuh

min-heat per burner or

for 20,200 Btuh Max-Heat/8,000

Btuh Min-Heat per burner.

4. Find closest natural gas heat value and specific gravity in

or

depending on furnace gas input rate.

5. Follow heat value and specific gravity lines to point of intersection

to find orifice size and maximum and minimum manifold pressure

settings for proper operation.

6. Check and verify burner orifice size in furnace. NEVER ASSUME

ORIFICE SIZE. ALWAYS CHECK AND VERIFY.

7. Replace original orifice with correct size, if required by

depending on furnace gas input rate. Use only

factory-supplied orifices, see EXAMPLE 1.

EXAMPLE 1 - 80,000 BTUH INPUT:

EXAMPLE: 0 - 2000 ft. (0 - 609.6M) altitude

Heating value = 1050 Btu/cu ft.

Specific gravity = 0.62

Therefore: Orifice No. 44

* Furnace is shipped with No. 44 orifices. In this example, all main

burner orifices are the correct size and do not need to be changed to

obtain proper input rate.

Manifold pressure: 3.4-in. w.c. for maximum heat, 0.55-in. w.c. for

minimum heat.

NOTE:

To convert gas manifold Table pressures to Pascals, multiply the

in. w.c. value by 249.1 Pa/in. w.c. (1 in. w.c. = 249.1 Pa).

Check Inlet Gas Pressure

The inlet gas pressure must be checked with the furnace operating in

maximum heat. This is necessary to make sure the inlet gas pressure

does not fall below the minimum pressure of 4.5 in. w.c. for natural gas.

The maximum inlet gas pressure is 13.6 in. of water column. If the inlet

pressure is too low, you will not be able to adjust the manifold pressure

to obtain the proper input rate. To check the inlet gas pressure:

1. Make sure the gas supply is turned off to the furnace and at the

electric switch on the gas valve.

2. Loosen set screw on inlet tower pressure tap no more than one full

turn with a 3/32-in. hex wrench or remove the 1/8 in. NPT plug

from the inlet pressure tap on the gas valve.

3. Connect a manometer to the inlet pressure tap on gas valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper the R to W/W1 and W2 thermostat connections at the

furnace control board.

8. When main burners ignite, confirm inlet gas pressure is Between

4.5 in. w.c. and 13.6 in. w.c.

9. Remove jumper across thermostat connections to terminate call for

heat. Wait until the blower off delay is completed.

10. Turn furnace gas valve electric switch to OFF position.

11. Turn gas supply manual shutoff valve to OFF position.

12. Turn off furnace power supply.

13. Remove manometer from the inlet pressure tap of the gas valve.

14. Tighten set screw on inlet tower pressure tap with 3/32-in. hex

wrench, or if 1/8-in. NPT plug was removed, apply pipe dope

sparingly to end of plug and re-install in the gas valve.

Adjust Manifold Pressure - Maximum Heat

For proper operation and long term reliability, the manifold pressure

must be adjusted /-2 percent of input rate on furnace rating plate.

The modulating furnace manifold pressure is set at two points. The first

point is Maximum Heat. The second point is Minimum Heat. Do not

adjust Intermediate Heat manifold pressure. Intermediate Heat manifold

pressure is checked as part of the temperature rise, but is not adjustable.

Always adjust Maximum Heat first, then Minimum Heat.

ALTITUDE

PERCENT

OF

DERATE

DERATE

MULTIPLIER

FACTOR*

FT.

M

0–2000

0-610

0

1.00

2001–3000

610-914

4-6

0.95

3001–4000

914-1219

6-8

0.93

4001–5000

1219-1524

8-10

0.91

5001–6000

1524-1829

10-12

0.89

6001–7000

1829-2134

12-14

0.87

7001–8000

2134-2438

14-16

0.85

8001–9000

2438-2743

16-18

0.83

9001–10,000

2743-3048

18-20

0.81

NOTICE

!

THERE ARE TWO MANIFOLD PRESSURE TABLES

Use Table 18 for all models EXCEPT (F/G)97CMN0602120

Use Table 19 for all models (F/G)97CMN0602120 ONLY

NOTICE

!

If orifice hole appears damaged or it is suspected to have been redrilled,

check orifice hole with a numbered drill bit of correct size. Never

redrill an orifice. A burr-free and squarely aligned orifice hole is

essential for proper flame characteristics.

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Inlet pressure tap set screw must be tightened and

⅛

-in. NPT pipe plug

must be installed to prevent gas leaks.