F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

55

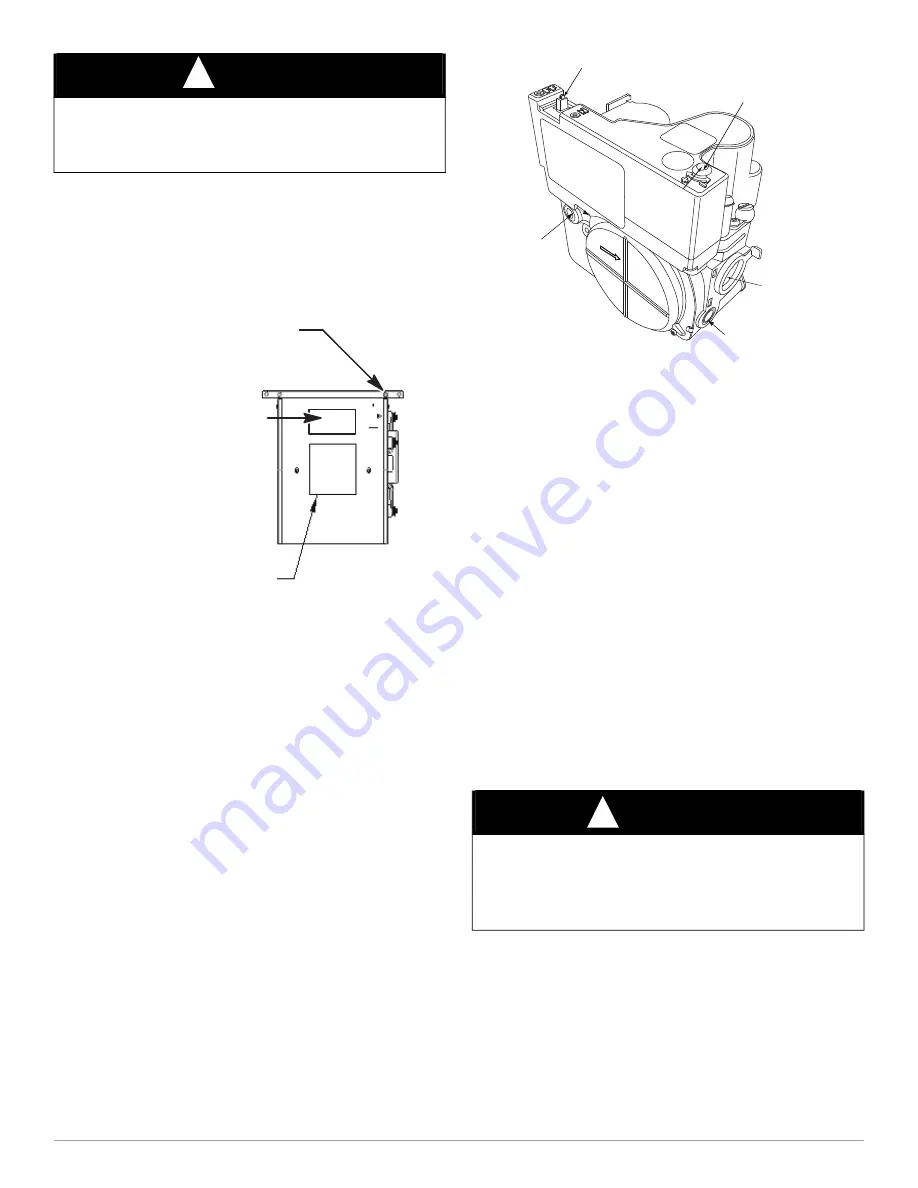

To adjust manifold pressure to obtain input rate for Maximum Heat:

1. Make sure the gas supply is turned off to the furnace and at the

electric switch on the gas valve.

2. Loosen set screw on manifold tower pressure tap no more than one

full turn with a 3/32-in. hex wrench, or remove the 1/8 in. NPT plug

from the manifold pressure tap on the gas valve, see

.

A170116

Fig. 61 – Gas Valve with Tower Pressure Ports

3. Connect a manometer to the outlet pressure tap on gas valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper the R to W/W1 and W2 thermostat connections at the

furnace control board.

8. After the main burners ignite and the blower starts, confirm

Maximum Heat manifold pressure is correct, based on the manifold

pressure tables in the installation instructions.

9. To adjust the Maximum Heat manifold pressure, slowly turn

adjusting screw counterclockwise to decrease manifold pressure or

clockwise to increase manifold pressure. Turn adjustment no more

than one click per second until you obtain the required manifold

A10496

Fig. 62 – Gas Valve without Tower Pressure Ports

10. Main burner flame should be clear blue, almost transparent.

11. After adjusting the Maximum Heat manifold pressure, remove

jumpers across thermostat connections to terminate the call for

heat.

12. Wait for blower off-delay to finish then reset 115-v power to

furnace.

Adjust Manifold Pressure - Minimum Heat

To adjust manifold pressure to obtain input rate for Minimum Heat:

1. Turn SW1-2 ON and SW4-2 must be OFF.

2. Jumper R and W/W1 thermostat connections on control to start

furnace.

3. After the main burners ignite and the blower starts, confirm

Minimum Heat manifold pressure is correct, based on the manifold

pressure tables in the installation instructions.

4. To adjust the Minimum Heat manifold pressure, slowly turn

adjusting screw counterclockwise to decrease manifold pressure or

clockwise to increase manifold pressure. Turn adjustment no more

than one click per second until you obtain the required manifold

pressure, see

5. After adjusting the manifold pressure, remove jumpers across

thermostat connections to terminate the call for heat. Wait until the

blower off delay is completed.

6. Move setup switch SW1-2 to the OFF position.

Clocking The Meter

Verify natural gas input rate by clocking meter.

NOTE:

Contact your HVAC distributor or gas supplier for metric gas

meter Tables, if required.

1. Turn off all other gas appliances and pilots served by the meter.

2. Move setup switches SW1-2 to ON position and SW4-2 to OFF.

This keeps furnace locked in low--heat operation when only W/W1

is energized or high heat operation when R to W/W1 and W2 are

jumpered.

NOTICE

!

DO NOT set Maximum Heat manifold pressure less than 3.2-in. w.c. or

more than 3.8 in. w.c. for natural gas. If required manifold pressure is

outside this range, change main burner orifices to obtain manifold

pressure in this range.

HEATER

WIRING

LABEL

LOCATION

MOTOR

GROUND

WIRE

MUST

BE

FASTENED

HERE

81,7

WIRING

LABEL

LOCATION

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Manifold pressure tap set screw must be tightened and

⅛

-in. NPT pipe

plug must be installed to prevent gas leaks.

ON/OFF Switch

1/2” NPT Outlet

Manifold

Pressure Tap

Inlet

Pressure Tap

Min/Max Heat Adust

(Under Cap)

GAS FL

OW

MODULATING

Turn screw 1 click per

second to adjust rate.

Clockwise to increase

rate, counter clockwise

to decrease rate.