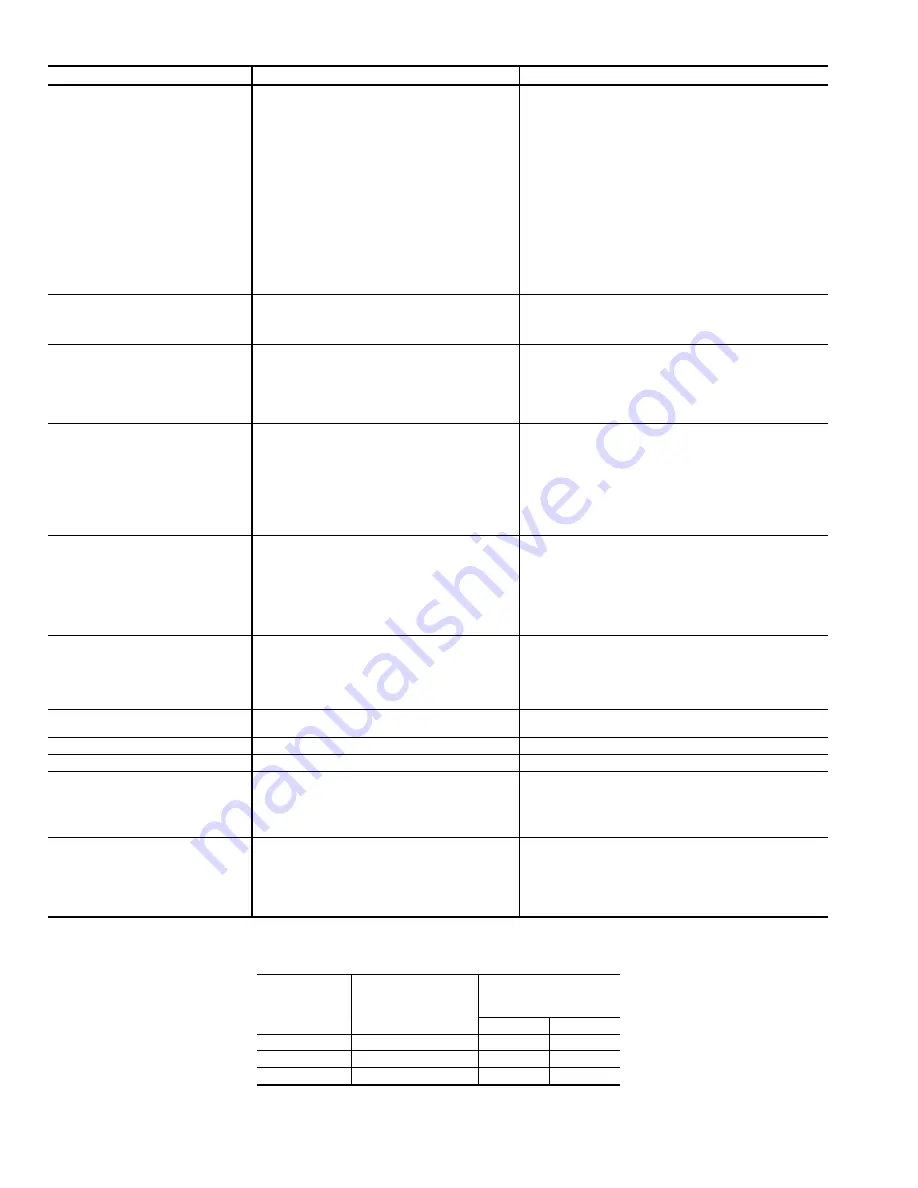

Table 19 — Troubleshooting

SYMPTOMS

CAUSE

REMEDY

COMPRESSOR DOES

NOT RUN

Power line open

Reset circuit breaker.

Control fuse open

Check control circuit for ground or short.

Replace fuse.

High-Pressure Switch (HPS)

tripped

Move LOCAL/ENABLE-STOP-CCN switch to STOP

position then back to RUN or CCN position.

Tripped power breaker

Check the controls. Find cause of trip

and reset breaker.

Loose terminal connection

Check connections.

Improperly wired controls

Check wiring and rewire.

Low line voltage

Check line voltage. Determine location

of voltage drop and remedy deficiency.

Compressor motor defective

Check motor winding for open or short.

Replace compressor if necessary.

Seized compressor

Replace compressor.

COMPRESSOR CYCLES OFF

ON LOW PRESSURE

Loss of charge

Repair leak and recharge.

Bad transducer

Replace transducer.

Low refrigerant charge

Add refrigerant.

COMPRESSOR SHUTS DOWN

ON HIGH PRESSURE

CONTROL

High-pressure control erratic in action

Replace control.

Compressor discharge valve partially closed

Open valve or replace if defective.

Condenser fan(s) not operating

Check wiring. Repair or replace motor(s)

if defective.

Condenser coil plugged or dirty

Clean coil.

UNIT OPERATES LONG OR

CONTINUOUSLY

Low refrigerant charge

Add refrigerant.

Control contacts fused

Replace control.

Partially plugged or plugged expansion

valve or filter driver

Clean or replace.

Defective insulation

Replace or repair.

Service load

Keep doors and windows closed.

Inefficient compressor

Check valves. Replace if necessary.

SYSTEM NOISES

Piping vibration

Support piping as required.

Expansion valve hissing

Add refrigerant.

Check for plugged liquid line filter drier.

Compressor noisy

Check valve plates for valve noise.

Replace compressor (worn bearings).

Check for loose compressor holddown bolts.

COMPRESSOR LOSES OIL

Leak in system

Repair leak.

Mechanical damage (blown piston or

broken discharge valve)

Repair damage or replace compressor.

Crankcase heaters not energized

during shutdown

Replace heaters, check wiring and

crankcase heater relay contacts.

FROSTED SUCTION LINE

Expansion valve admitting either too

much or too little refrigerant

Check cooler and compressor thermistors.

Test EXV.

HOT LIQUID LINE

Shortage of refrigerant due to leak

Repair leak and recharge.

FROSTED LIQUID LINE

Shutoff valve partially closed or restricted

Open valve or remove restriction.

COMPRESSOR DOES NOT

UNLOAD

Burned out coil

Replace coil.

Defective capacity control valve

Replace valve.

Miswired solenoid

Rewire correctly.

Weak, broken, or wrong valve body spring

Replace spring

COMPRESSOR DOES NOT

LOAD

Miswired solenoid

Rewire correctly.

Defective capacity control valve

Replace valve.

Plugged strainer (high side)

Clean or replace strainer.

Stuck or damaged unloader piston or

piston ring(s)

Clean or replace the necessary parts.

EXV — Electronic Expansion Valve

Table 20 — Standard and Accessory Unloaders

UNIT

NO. OF STANDARD

UNLOADER(s)

NO. OF ACCESSORY

UNLOADERS

PERMITTED

Circuit A

Circuit B

30GN040-070

1

1

1 or 2

30GN080-170*

2

1

1

30GN190-210*

0

1

1

*And associated modular units.

66

Summary of Contents for Flotronic II 30GN040

Page 71: ......