9

• Inspect the return-air duct connection(s) at the furnace to

ensure it is physically sound, sealed to the furnace casing,

and terminates outside the space containing the furnace.

• Inspect electrical wiring, connections, and components for

loose connections.

• Perform an operational checkout to determine whether

your furnace is working properly and if it requires

adjustments.

• Inspect all condensate drain tubes and condensate trap

assembly for leaks. The condensate removal system should

be cleaned annually by a qualified service agency. Refer

to the Service and Maintenance Instructions for further

information.

• Examine the physical support of the furnace. Support

should be sound with no cracks, sagging, gaps, etc. around

the base.

• Check furnace for any obvious signs of deterioration.

BEFORE YOU REQUEST A SERVICE CALL

If your furnace is not operating or not performing properly,

you may save the expense of a service call by checking a few

things yourself before calling for service.

FOR INSUFFICIENT AIRFLOW:

• Check for dirty air filter(s).

• Check for blocked return-air or supply-air grilles through-

out your home. Ensure they are open and unobstructed.

If problem still exists, call your dealer for service.

IF FURNACE FAILS TO OPERATE:

Follow this checklist step by step, advancing to the next step

only if furnace fails to start.

• Check thermostat for proper temperature. Is thermostat

set above room temperature?

• Is thermostat switch on HEAT?

• Check fuses and circuit breakers. Is electrical supply on?

• Is manual shut-off valve in gas supply pipe in open posi-

tion? (Follow start-up procedures if you open gas valve.)

NOTE:

Turn off electrical supply before continuing with

checklist.

• Is control knob on gas valve in ON position? (Follow start-

up procedures if you must reset knob to ON.)

• Check manual reset flame rollout switch located on the

burner box. (See Fig. 2 or 3.) If furnace has experienced high

temperature conditions, this switch will shut off the furnace.

Reset it by pushing the button on the switch. If it trips again,

shut down the furnace and call for service. See section “Shut-

ting Down Your Furnace” in this manual.

• Check for obstructions around the vent termination.

If the furnace still fails to operate, call your service

representative.

For your convenience, record the furnace product and serial

numbers on page 2. Should you ever require service, you

will have ready access to the information needed by your

service representative.

This furnace has an LED operation and fault code display

to aid the installer, service technician, or homeowner

while installing or servicing the unit. The LED code can

be seen by removing the access door and viewing the

LED(s) through the view port in the blower access panel.

NOTE:

Removing the blower access panel or turning off the

115-v electrical power supply will terminate LED diagnostic

code display.

To decipher the meaning of the LED code, and suggested

action, the following cross-reference can be used.

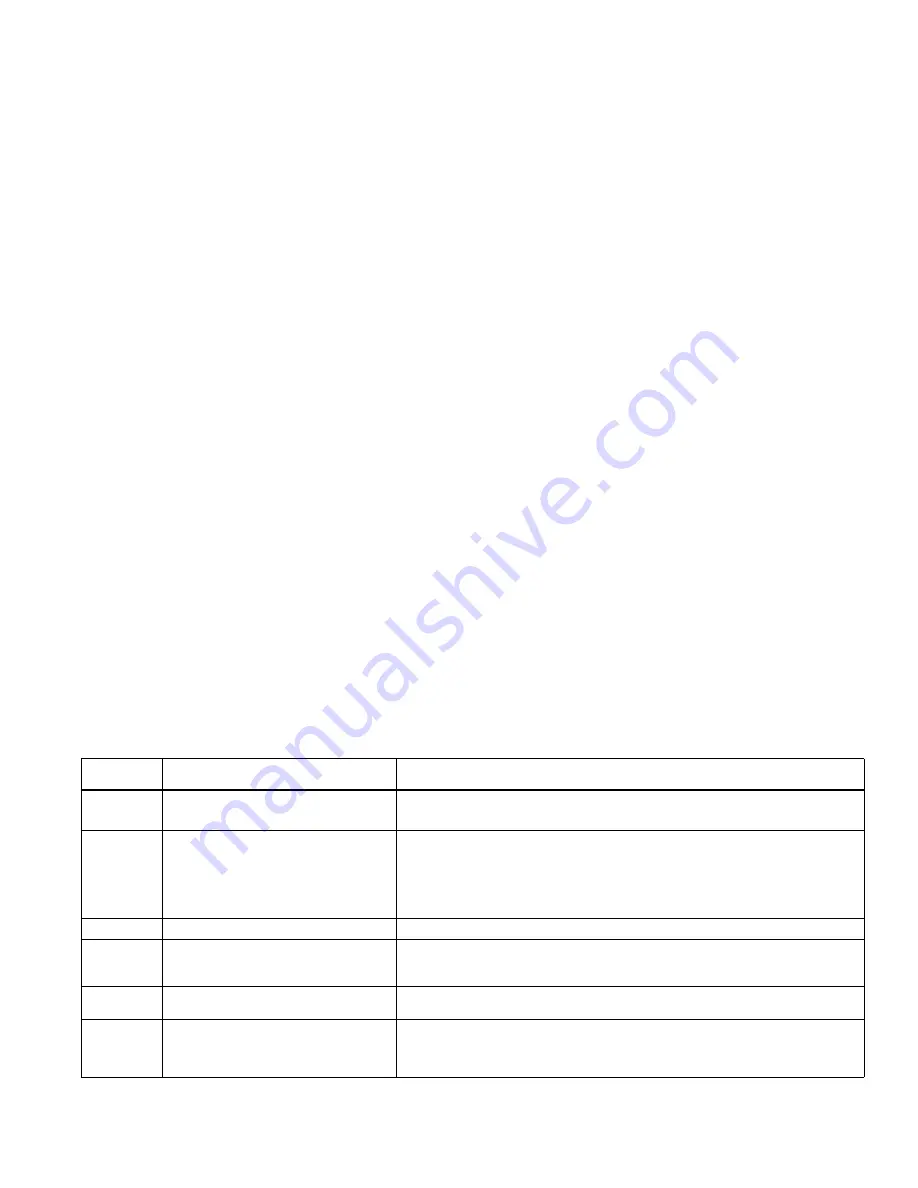

MODEL 58MCA and 58MXA DIAGNOSTIC CHART

(See Fig. 3.)

NOTES:

1. Light on continuously means control has power and working properly.

2. The status codes are a 2 digit number. The first digit is determined by the number of short flashes of the light and the second digit is determined by number of

long flashes of the light.

FAULT

CODE

FAULT CODE DESCRIPTION

CHECKLIST

13 or 33

Limit Switch Lockout

M

Check for dirty air filter.

M

Check for blocked return-air or supply-air grilles.

14 or 34

Ignition Lockout or

Ignition Proving Fault

M

Check to be sure manual shut-off valve in gas supply pipe is in the open position. (Follow start-up proce-

dure if you open gas line.)

NOTE:

Turn off the electrical supply and remove access doors before continuing with this

checklist.

M

Check to be sure control knob on gas valve is in ON position. (Follow start-up procedures if you must reset

dial to ON.)

24

Furnace Fuse Open

M

Check for blown fuse and possible short in 24-v wiring.

31

Pressure Switch Not Closed

M

Check to make sure that all PVC pipes leading into the combustion-air intake and vent/exhaust are free

from any cracks and sags. Also check the combustion-air intake and vent/exhaust pipes on the outside of

your home for blockage.

12, 21, 22,

or 23

Any Other

Fault Code

M

Call dealer for service.

No Fault

Code

Signaled

Furnace Fails to Operate and No

Fault is Signaled

M

Check thermostat for proper temperature setting.

M

Check for blown fuses and circuit breakers.

M

Check to be sure blower access panel is properly in place.