7

2.7.2

B

URNER WITH

O

UTDOOR

C

OMBUSTION

A

IR

K

IT

Certain burners are designed to function with combustion air

taken directly from the outside. Follow the instructions provided

with the burner, the fresh-air supply kit or the side-wall venting

kit.

2.8 OIL

TANK

WARNING

Fire and explosion hazard.

Use only approved heating type oil in this furnace.

DO NOT USE waste oil, used motor oil, gasoline or

kerosene.

Use of these will result in death, bodily injury and/or

property damage.

CAUTION

When a 0.75 USGPH or smaller nozzle is used, a 10 micron or

finer filter, must be installed on the oil supply line to the

furnace inside the building where the unit is located.

This is a requirement in order for the heat exchanger warranty

to remain in force.

Check your local codes for the installation of the oil tank and

accessories.

At the beginning of each heating season or once a year, check

the complete oil distribution system for leaks.

Ensure that the tank is full of clean oil. Use No.1 or No.2

Heating Oil (ASTM D396 U.S.) or in Canada, use No.1 or No.2

Furnace Oil.

A manual shut-off valve and an oil filter shall be installed in

sequence from tank to burner. Be sure that the oil line is clean

before connecting to the burner. The oil line should be

protected to eliminate any possible damage. Installations

where the oil tank is below the burner level must employ a two-

pipe fuel supply system with an appropriate fuel pump. A rise

of 2.4 m (8') and more requires a two stage pump and a rise

greater than 4.9 m (16') an auxiliary pump. Follow the pump

instructions to determine the size of pipe needed in relation to

the rise or to the horizontal distance.

2.9 DUCTING

WARNING

Poisonous carbon monoxide gas hazard.

DO NOT draw return air from inside a closet or utility

room. Return air MUST be sealed to the furnace casing.

Failure to properly seal ducts can result in death, bodily

injury and/or property damage.

The ducting must be designed and installed according to

approved methods, local and national codes as well as good

trade practices.

When ducting supplies air to a space other than where the

furnace is located, the return air must be sealed and also be

directed to the space other than where the furnace is located.

2.9.1

A

IR FILTER

A properly sized air filter must be installed on the return air

side of the unit. Refer to the Technical Specifications,

table 7, for the correct dimensions. Also refer to the

instructions supplied with the filter.

2.9.2

SUPPLY AIR ADJUSTMENT

(4

SPEED

MOTOR

)

On units equipped with 4-speed blower motors, the supply

air must be adjusted based on heating/air conditioning

output and the static pressure of the duct system. For the

desired air flow refer to the following table as well as the

air flow tables based on static pressure in the Technical

Specifications section of this manual.

Table 1: Blower speed adjustments (heating mode, 4

speed motor)

HEATING

CAPACITY

(USGPH)

STATIC

PRESSURE

(W.C.)

RECOMMENDED

BLOWER SPEED

0.55

0.25” MED-LOW

0.55

0.50” MED-LOW

0.70

0.25” MED-HIGH

0.70

0.50” HIGH

Table 2: Blower speed adjustments (A/C mode, 4

speed motor)

A/C CAPACITY

(TONS)

RECOMMENDED

BLOWER SPEED

2.0

MED-LOW

2.5

MED-HIGH

3.0

HIGH

To effect the adjustment, the RED (for heating) and BLUE

(for cooling and heat pump) wires can be changed on the

motor. Also, refer to the position of the wires on the

electronic board of the unit and consult the wiring

diagrams. If the heating and air conditioning speeds are

the same, the RED wire must be moved to “UNUSED

LEADS” on the electronic board and the jumper provided

with the BLUE wire must be used between the “HEAT”

and “COOL” terminals.

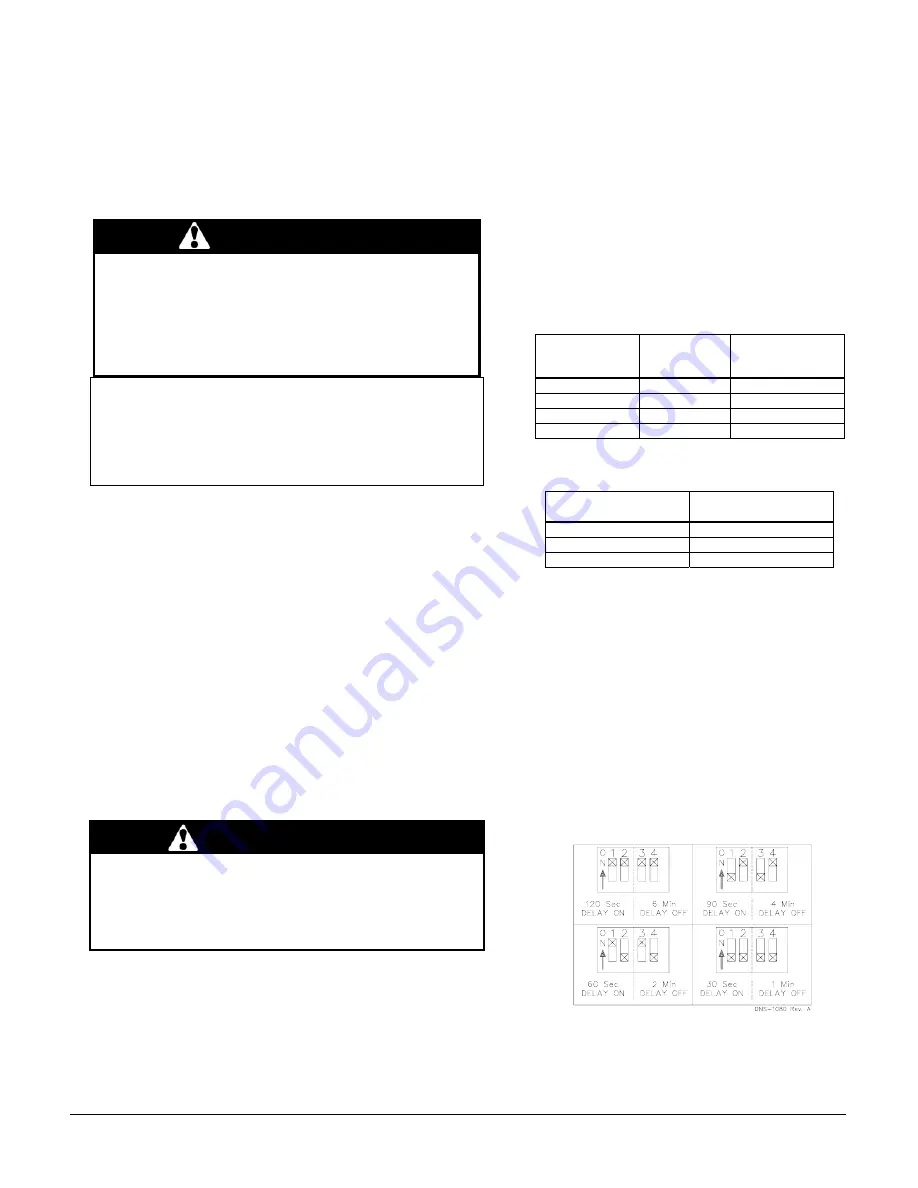

The blower start/stop delays can be adjusted by

positioning the DIP switches on the electronic board as

shown in the following figures. However, the

recommended adjustments are 60 seconds blower ON

delay and 2 minutes blower OFF delay.

Figure 5: Blower start / stop delays - Board #1158

2.10

SUPPLY AIR ADJUSTMENT (ECM

VARIABLE SPEED MOTORS)

On units equipped with ECM variable speed blower

motors, the air supply must be adjusted based on

Summary of Contents for OBL098

Page 16: ...16 Figure 6 Furnace Dimensions ...

Page 17: ...17 Figure 7 Wiring Diagram 4 Speed Motor PSC ...

Page 18: ...18 Figure 8 Wiring Diagram Variable Speed Motor ECM ...

Page 19: ...19 Figure 9 Parts List With 4 Speed motor PSC B50082E ...

Page 21: ...21 Figure 10 Parts List With variable speed motor ECM B50083E ...

Page 23: ......

Page 24: ......

Page 29: ...Figure 8 Diagramme électrique Moteur vitesse variable ECM 20 ...