T-309

4-1

SECTION 4

OPERATION

4.1 INSPECTION (Before Starting)

WARNING

Beware of unannounced starting of the

evaporator and condenser fans. The unit

may cycle the fans and compressor unex-

pectedly as control requirements dictate.

a. If container is empty, check inside for the following:

1. Check channels or “T” bar floor for cleanliness.

Channels must be free of debris for proper air cir-

culation.

2. Check container panels, insulation and door seals for

damage. Effect permanent or temporary repairs.

3. Visually check evaporator fan motor mounting bolts

for proper securement (refer to paragraph 6.17).

4. Check for dirt or grease on evaporator fan or fan deck

and clean if necessary.

5. Check evaporator coil for cleanliness or obstruc-

tions. Wash with fresh water.

6. Check defrost drain pans and drain lines for obstruc-

tions and clear if necessary. Wash with fresh water.

7. Check panels on refrigeration unit for loose bolts and

condition of panels. Make sure T.I.R. devices are in

place on access panels.

b. Check condenser coil for cleanliness. Wash with

fresh water.

c. Open control box door. Check for loose electrical

connections or hardware.

d. Check color of moisture-liquid indicator.

e. Check oil level in compressor sight glass.

4.2 CONNECT POWER

WARNING

Do not attempt to remove power plug(s) be-

fore turning OFF start-stop switch (ST),

unit circuit breaker(s) and external power

source.

WARNING

Make sure the power plugs are clean and dry

before connecting to any power receptacle.

4.2.1 Connection To 380/460 vac Power

1. Make sure start-stop switch (ST, on control panel)

and circuit breaker (CB-1, in the control box) are in

position “0” (OFF).

2. Plug the 460 vac (yellow) cable into a de-energized

380/460 vac, 3-phase power source. Energize the

power source. Place circuit breaker (CB-1) in posi-

tion “I” (ON). Close and secure control box door.

4.3 ADJUST FRESH AIR MAKEUP VENT

The purpose of the fresh air makeup vent is to provide

ventilation for commodities that require fresh air

circulation. The vent

must be closed

when transporting

frozen foods.

Air exchange depends on static pressure differential,

which will vary depending on the container and how the

container is loaded.

4.3.1 Upper Fresh Air Makeup Vent

Two slots and a stop are designed into the disc for air

flow adjustments. The first slot allows for a 0 to 30% air

flow, and the second slot allows for a 30 to 100% air

flow. To adjust the percentage of air flow, loosen the

wing nut and rotate the disc until the desired percentage

of air flow matches with the arrow. Tighten the wing

nut. To clear the gap between the slots, loosen the wing

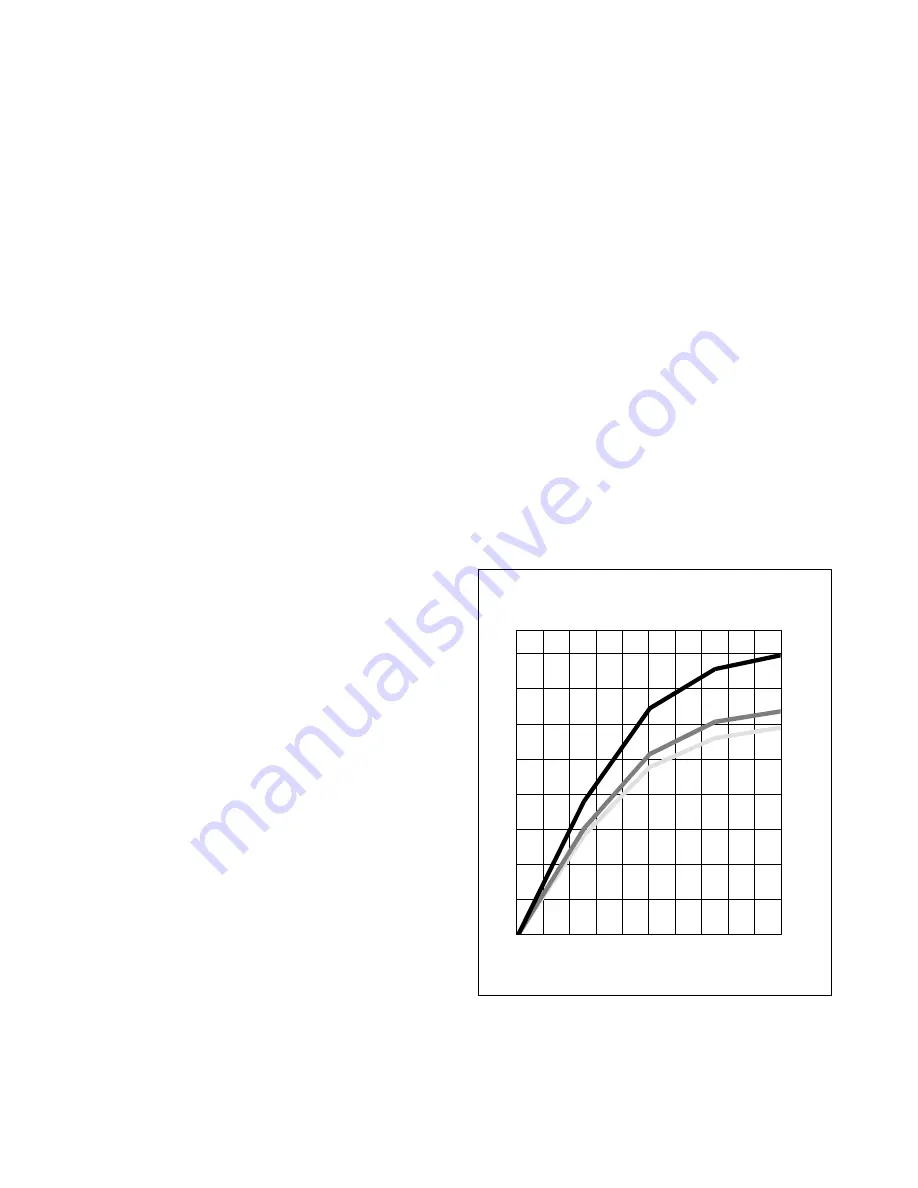

nut until the disc clears the stop. Figure 4-1 gives air

exchange values for an empty container. Higher values

can be expected for a fully loaded container.

0

30

60

90

120

150

180

210

240

0

10 20 30 40 50 60 70 80 90 100

AIR

FLOW

(CMH)

1-

!

/

2

”

PERCENT OPEN

69NT FRESH AIR MAKEUP

T-BAR

2-

%

/

8

”

3”

T-BAR

T-BAR

ZERO EXTERNAL STATIC 50HZ

For 60HZ operation multiply curves by 1.2

Figure 4-1 Make Up Air Flow Chart