6

Increasing fan speed increases load on the motor. Do not

exceed maximum speed specified in the Product Data or

motor amperage listed on the unit rating plate.

5. Set the movable flange at the nearest keyway or flat of the

pulley hub and tighten the setscrew to torque of 72 ± 5 in.-lb

(8.14 ± 0.56 Nm).

Aligning the Fan and Motor Pulleys

1. Loosen the fan pulley setscrews.

2. Slide the fan pulley along the fan shaft. Make angular align

-

ment by loosening the motor from its mounting. See Fig. 8.

3. Tighten the fan pulley setscrews and motor mounting bolts to

torque specifications.

4. Recheck the belt tension. See Fig. 6.

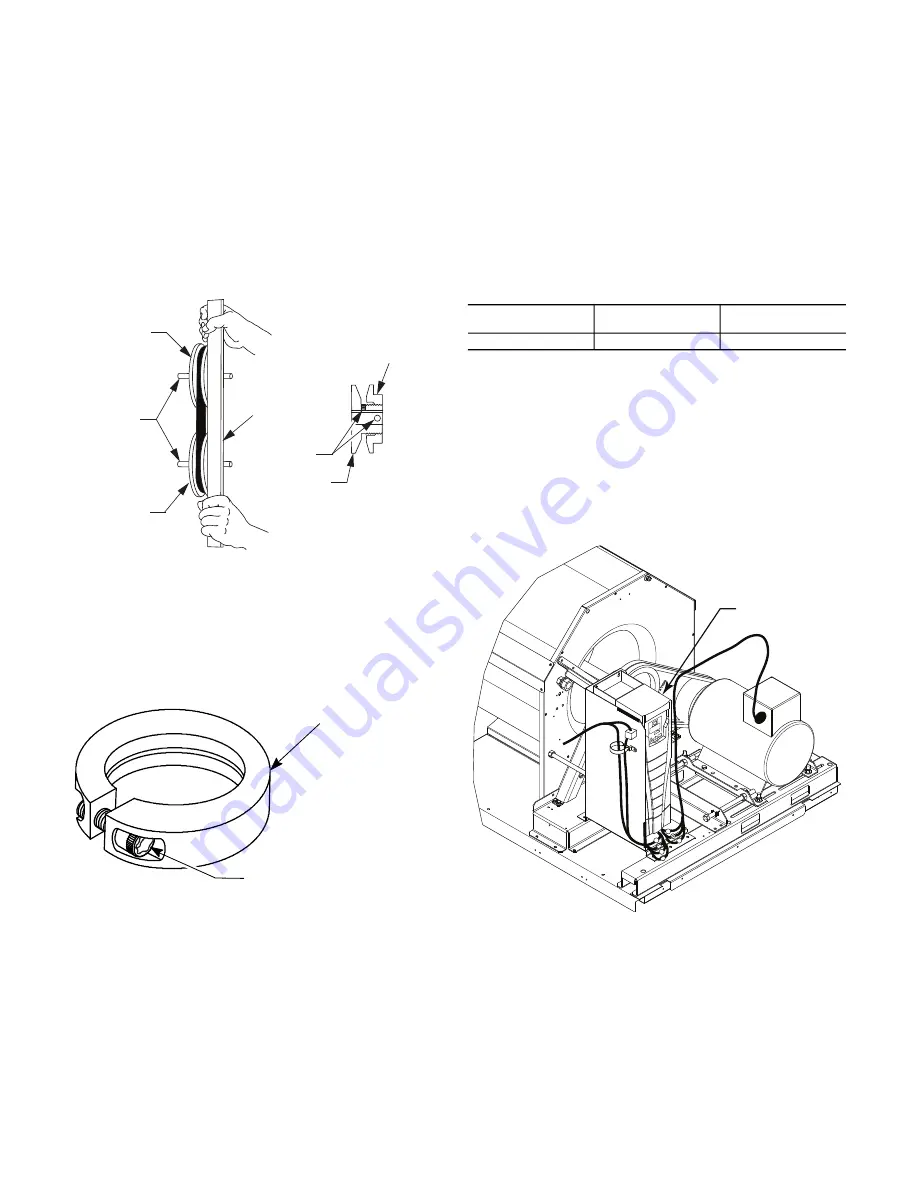

Fig. 8 —

Supply-Fan Pulley Adjustment

BEARINGS

This fan system uses bearings featuring concentric split locking

collars. The collars are tightened through a cap screw bridging the

split portion of the collar. The cap screw has a Torx T25 socket

head. To tighten the locking collar: Hold the locking collar tightly

against the inner race of the bearing and torque the cap screw to

65 to 70 in-lb. (7.4 to 7.9 Nm). See Fig. 9.

Fig. 9 —

Tightening Locking Collar

STAGED AIR VOLUME (SAV) CONTROL: 2-

SPEED FAN WITH VARIABLE FREQUENCY

DRIVE (VFD)

Staged Air Volume (SAV) Indoor Fan Speed

System

NOTE: The SAV option is not available on units with Humidi-

MiZer adaptive humidification system.

The SAV system utilizes a fan speed control board and Variable

Frequency Drive (VFD) to automatically adjust the indoor fan

motor speed in sequence with the unit’s ventilation, cooling and

heating operation. Conforming to ASHRAE 90.1 2010 Standard

Section 6.4.3.10.b, during the first stage of cooling operation the

SAV system will adjust the fan motor to provide 66% of the de

-

sign airflow rate for the unit. When the call for the second stage of

cooling is required, the SAV system will allow the design airflow

rate for the unit established (100%). During the heating mode, the

SAV system will allow total design airflow rate (100%) operation.

During ventilation mode, the SAV system will operate the fan mo

-

tor at 66% speed.

Identifying Factory Option

This section only applies to units that meet the criteria detailed in

Table 1. See Appendix A for the model number nomenclature

breakdown.

Unit Installation with SAV Option

50TC ROOFTOP

Refer to the base unit installation instructions for standard required

operating and service clearances.

NOTE: The Remote VFD Keypad is a field-installed option. It is

not included as part of the factory-installed VFD option. See

“Variable Frequency Drive (VFD) Installation, Setup and Trouble

-

shooting Supplement” for wiring schematics and performance

charts and configuration. See Fig. 10 for location of the VFD as

mounted on the various 50TC models.

Fig. 10 —

VFD Location for 50TC 15-27.5 Units

ADDITIONAL VFD INSTALLATION AND

TROUBLESHOOTING

Additional installation, wiring and troubleshooting information

for the VFD can be found in the following manuals: “Variable Fre

-

quency Drive (VFD) Installation, Setup and Troubleshooting Sup

-

plement.”

MOTOR

When replacing the motor, use the following steps. See Fig. 11.

STRAIGHT EDGE

MUST BE PARALLEL

WITH BELT

SETSCREWS

MOTOR AND

FANSHAFTS

MUST BE

PARALLEL

FIXED FLANGE

MOVABLE

FLANGE

SINGLE - GROOVE

FAN PULLEY

MOTOR PULLEY

T --- 25 TORX SOCKET

HEAD CAP SCREW

LOCKING COLLAR

Table 1 —

Model-Size / VFD Option Indicator

UNIT

POSITION

IN MODEL NUMBER

VDP FIOP

INDICATOR

50TC 17-30

17

G, J

VARIABLE

FREQUENCY

DRIVE (VFD)

Summary of Contents for WeatherMaker 50TC 17-30 Series

Page 34: ...34 Fig 48 RTU Open Overlay for Economizer Wiring ...

Page 35: ...35 Fig 49 VFD Overlay for W2770 Controller Wiring ...

Page 80: ...80 Fig C 50TC 17 28 Control Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 81: ...81 Fig D 50TC 30 Control Wiring Diagram 208 230 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 82: ...82 Fig E 50TC 30 Control Wiring Diagram 460 3 60 575 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 83: ...83 Fig F 50TC 17 30 Power Wiring Diagram 208 230 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 84: ...84 Fig G 50TC 17 30 Power Wiring Diagram 460 3 60 575 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 89: ...89 Fig L 50TC PremierLink System Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 90: ...90 Fig M 50TC RTU Open Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 91: ...91 Fig N 50TC SAV VFD System Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 93: ......