33

TROUBLESHOOTING SUPPLY FAN MOTOR OVER

-

LOAD TRIPS

The supply fan used in 50TC units is a forward-curved centrifu

-

gal wheel. At a constant wheel speed, this wheel has a character

-

istic that causes the fan shaft load to DECREASE when the stat

-

ic pressure in the unit-duct system increases and to INCREASE

when the static pressure in the unit-duct system decreases (and

fan airflow rate increases). Motor overload conditions typically

develop when the unit is operated with an access panel removed,

with unfinished duct work, in an economizer-open mode, or a

leak develops in the duct system that allows a bypass back to

unit return opening.

CONDENSER FAN MOTOR PROTECTION

The condenser fan motor is internally protected against

overtemperature.

Control Circuit, 24v

The control circuit is protected against overcurrent conditions by a

circuit breaker mounted on the control transformer TRAN. Reset

is manual.

The factory-installed PremierLink Controller includes the supply-

air temperature (SAT) sensor. The outdoor air temperature (OAT)

sensor is included in the FIOP/accessory EconoMi$er 2 package.

NOTE: Refer to PremierLink Installation, Start-Up and Configu

-

ration Instructions. Have a copy of this manual available at unit

start-up.

PremierLink™ Control

For details on operating units equipped with the factory-installed

PremierLink controller option, refer to the

PremierLink Retrofit

Rooftop Controller Version 3.x Installation, Start-Up, and Config

-

uration Instructions

manual.

RTU Open Control System

For details on operating units equipped with the factory-installed

RTU Open controller, refer to the

Factory-Installed RTU Open

Multi-Protocol Controller Control, Start-Up, Operation and Trou

-

bleshooting

manual.

ECONOMI$ER SYSTEMS

The 50TC units may be equipped with a factory-installed or acces

-

sory (field-installed) EconoMi$er system. Three types are avail

-

able: with a logic control system (EconoMi$er IV and

EconoMi$er X) and without a control system (EconoMi$er2). See

Fig. 45-47 for component locations on each type. The W7212

controller is used for EconoMi$er IV and the W7220 controller is

used for EconoMi$er X. See Fig. 48-51 for EconoMi$er section

wiring diagrams.

All three EconoMi$er system use direct-drive damper actuators.

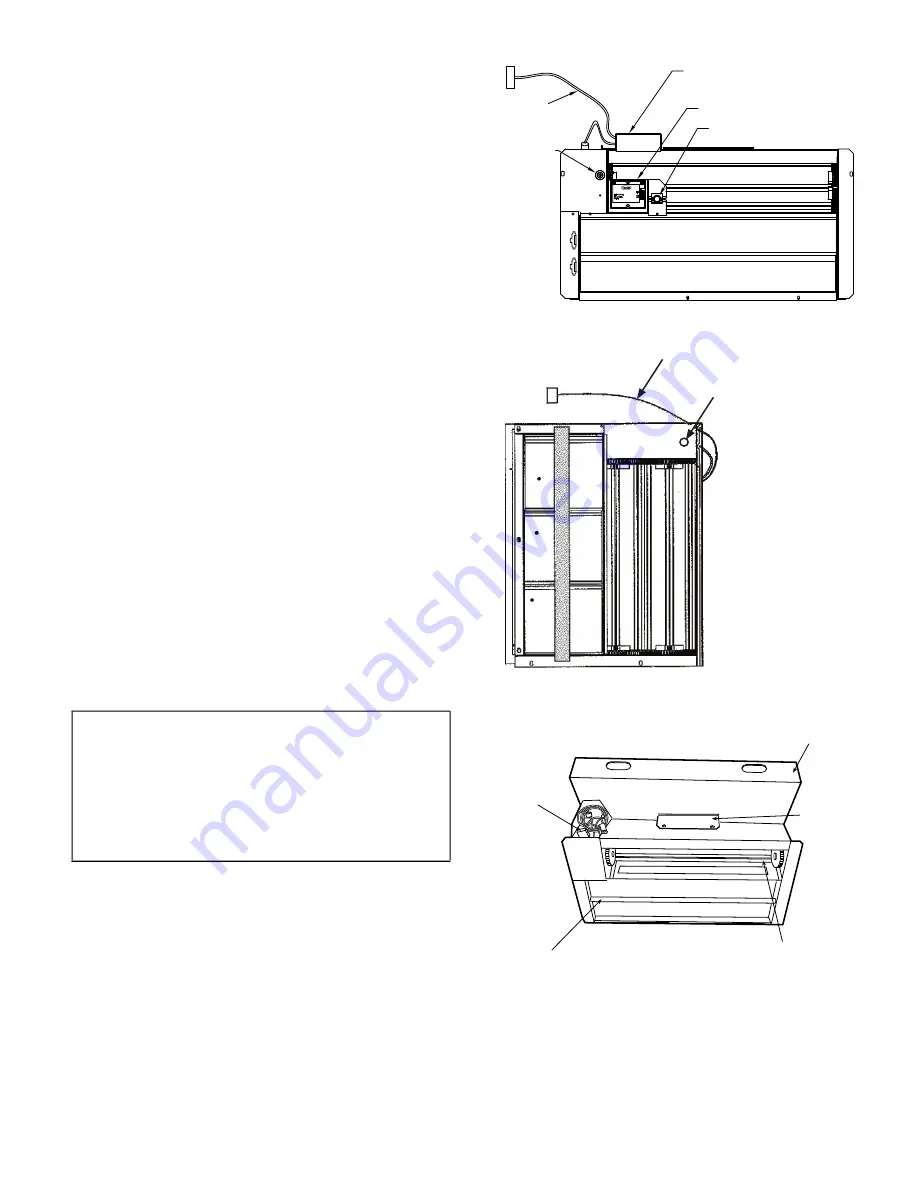

Fig. 45 —

EconoMi$er IV Component Locations

Fig. 46 —

EconoMi$er X Component Locations

Fig. 47 —

EconoMi$er 2 Component Locations

IMPORTANT: Any economizer that meets the economizer re

-

quirements as laid out in California’s Title 24 mandatory sec

-

tion 120.2 (fault detection and diagnostics) and/or prescriptive

section 140.4 (life-cycle tests, damper leakage, 5 year warranty,

sensor accuracy, etc), will have a label on the economizer. Any

economizer without this label does not meet California’s

Title 24. The five-year limited parts warranty referred to in sec

-

tion 140.4 only applies to factory installed economizers. Please

refer to the economizer on the unit.

ECONOMI$ER IV

CONTROLLER

OUTSIDE AIR

TEMPERATURE SENSOR

LOW AMBIENT

SENSOR

ACTUATOR

WIRING

HARNESS

OUTSIDE AIR

TEMPERATURE SENSOR

WIRING HARNESS

ECONOMI$ER2

PLUG

BAROMETRIC

RELIEF

DAMPER

OUTDOOR

AIR HOOD

HOOD

SHIPPING

BRACKET

GEAR DRIVEN

DAMPER

Summary of Contents for WeatherMaker 50TC 17-30 Series

Page 34: ...34 Fig 48 RTU Open Overlay for Economizer Wiring ...

Page 35: ...35 Fig 49 VFD Overlay for W2770 Controller Wiring ...

Page 80: ...80 Fig C 50TC 17 28 Control Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 81: ...81 Fig D 50TC 30 Control Wiring Diagram 208 230 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 82: ...82 Fig E 50TC 30 Control Wiring Diagram 460 3 60 575 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 83: ...83 Fig F 50TC 17 30 Power Wiring Diagram 208 230 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 84: ...84 Fig G 50TC 17 30 Power Wiring Diagram 460 3 60 575 3 60 Units APPENDIX D WIRING DIAGRAMS ...

Page 89: ...89 Fig L 50TC PremierLink System Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 90: ...90 Fig M 50TC RTU Open Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 91: ...91 Fig N 50TC SAV VFD System Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 93: ......