12

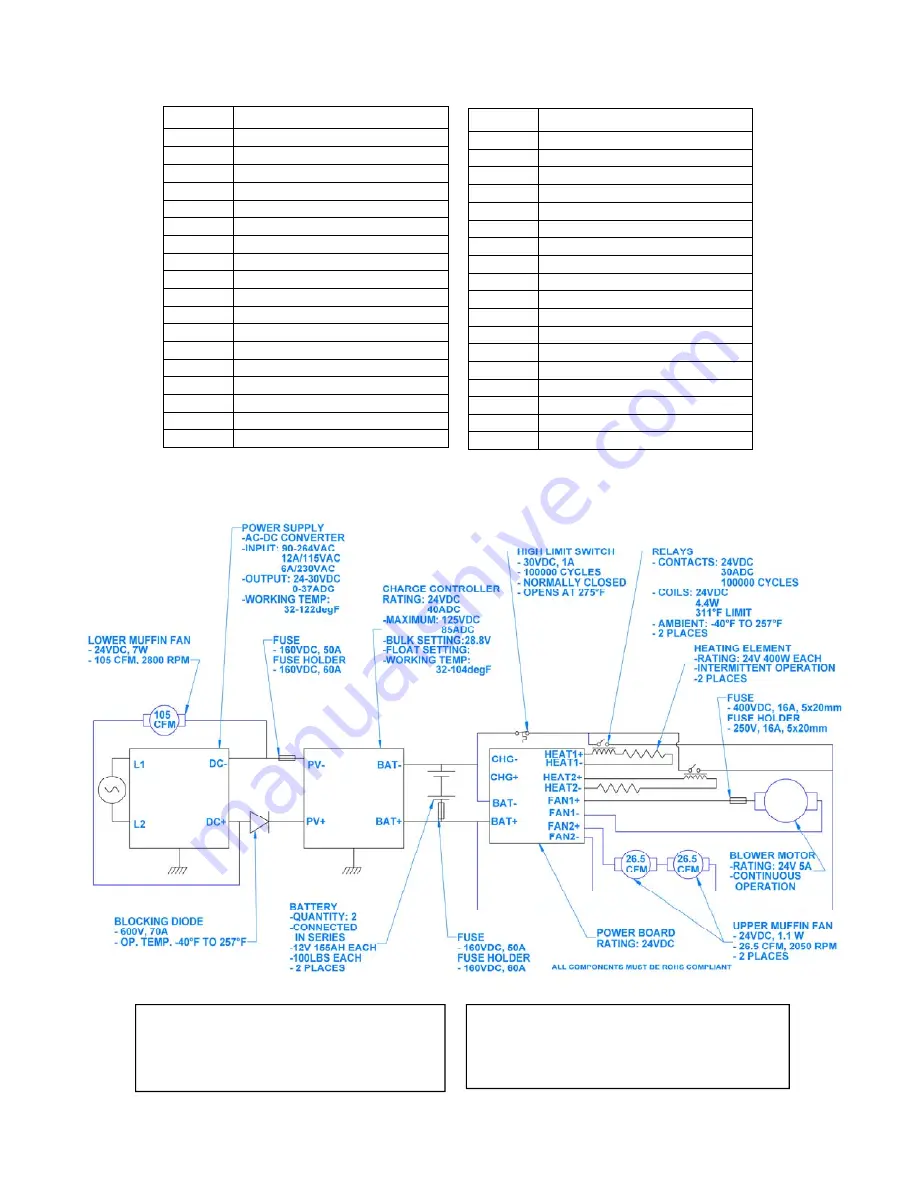

WIRING DIAGRAM & PARTS LIST

Part Number Description

18100-0159

Locking Spring Plunger

18301-5284

6” Red Rigid Caster

18301-5293

6” Red Swivel Caster with Brake

18301-8321

Threaded Stem Ball Caster

18302-0110

Link Lock Spring

18303-0082

Snap-in Pocket Pull

18312-0671

Battery Compartment Overlay

18312-0673 Control

Overlay

18600-0142

275F Hi-Limit-Auto QC Gold

18602-0309

Fuse 16 Amp, 400VDC, 5x20mm

18602-0312

Fuse Holder, 16A, 32VDC

18602-0317

Class - Fuse, 50A

18602-0318

Fuse Holder, Class-T 300V

18602-0319

Relay-24VDC Coil, 30A cont.

18603-0004 Wiring

Kit

18603-0006

3’ Patch Cord

18603-0007

AC Detection Cord

18603-5018

Fan

Blade

1300W, 120V,

10.8A, 60Hz, single

phase, NEMA 5-20P

Part Number Description

18605-0017

14/3 HSJO Cord w/ 5-20 Plug

18607-0019

Terminal Block 6 pos. #603

18612-0162

Hoop Element #1 400W

18612-0163

Hoop Element #2 400W

18614-0272

Fan Guard, #SC120-W15

18614-0275

Fan Guard, #SC80-W2

18614-0303

Muffin Fan, 24VDC, 26 CFM

18614-0392

Blower Motor, 24VDC, 1500 RPM

18614-0393

4.72”x1.57” 24VDC 105 CFM

18616-0399

Xantrex C40 CHRG Controller

18616-0401

12V, 540WPC 155AH Battery

18616-0402

Gridless Hot Display Board

18616-0404

Gridless Hot Power Board

18616-0405 Thermistor, 50K, 4” Probe

18616-0406

Blocking Diode, 600V, 70A

18616-0408

Power Converter, 1200W, 30VDC

18616-9998

Cord

Grip

29034-0282

Silicone

Sponge

NOTE:

The technical content of this manual, including any wir-

ing diagrams, schematics, parts breakdown illustrations

and / or adjustment procedures, is

intended for use

ONLY by qualified technical personnel

.

NOTE:

For warranty service, call Carter-Hoffmann direct at 800-

323-9793 for authorization, we will dispatch the nearest

authorized service agency.

Summary of Contents for GTH12

Page 13: ...WIRING SCHEMATIC 13...