Reference Manual V1.10

Software Versions 3.xx

X300-621-110

Page 1

Table of Contents

1.

INTRODUCTION ................................................................................................................... 4

1.1.

Overview .................................................................................................................... 4

1.2.

Approvals ................................................................................................................... 4

1.2.1.

Trade versions ............................................................................................ 5

1.3.

The Manuals Set ........................................................................................................ 5

1.4.

Document Conventions .............................................................................................. 5

2.

SPECIFICATIONS ................................................................................................................. 6

3.

INSTALLATION .................................................................................................................... 7

3.1.

Introduction ................................................................................................................ 7

3.2.

General Warnings ...................................................................................................... 7

3.3.

Electrical Safety .......................................................................................................... 7

3.4.

Cleaning ..................................................................................................................... 7

3.5.

Cable Connections ..................................................................................................... 8

3.6.

DC Power (DC PWR + , DC PWR

–) .......................................................................... 8

3.7.

Load Cell Connection ................................................................................................. 8

3.7.1.

Load Cell Signals and Scale Build .............................................................. 8

3.7.2.

4-Wire Connection ...................................................................................... 9

3.7.3.

6-Wire Connection ...................................................................................... 9

3.8.

Auxiliary Connections ................................................................................................. 9

3.8.1.

RS-232 Serial ........................................................................................... 10

3.8.2.

Remote Input ............................................................................................ 13

3.8.3.

Outputs ..................................................................................................... 14

3.9.

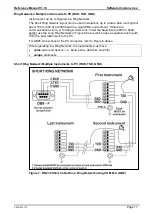

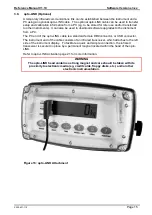

opto-LINK (Optional) ................................................................................................. 15

3.10.

Connecting Shields................................................................................................... 16

3.10.1.

Cable Shield Connection and Earthing ..................................................... 16

3.11.

Regulatory Sealing Requirements ............................................................................ 16

4.

DATA ENTRY ...................................................................................................................... 17

4.1.

Editing Annunciators ................................................................................................. 17

4.2.

Numeric Entry ........................................................................................................... 18

4.3.

Selections and Options ............................................................................................. 18

5.

BASIC OPERATION ........................................................................................................... 19

5.1.

Display ..................................................................................................................... 19

5.2.

Has a key been locked? ........................................................................................... 20

5.3.

Editing Function ........................................................................................................ 20

5.4.

Stability

– What is a “Stable Error”? .......................................................................... 20

5.5.

POWER Key............................................................................................................. 20

5.6.

ZERO Key ................................................................................................................ 21

5.7.

TARE Key ................................................................................................................ 21

5.8.

GROSS/NET Key ..................................................................................................... 21

5.9.

PRINT Key ............................................................................................................... 22

5.10.

FUNCTION Key ........................................................................................................ 22

6.

CONFIGURATION............................................................................................................... 23

6.1.

General Setup Information ........................................................................................ 23

6.2.

Basic Weighing Terminology .................................................................................... 23

6.3.

Filtering Techniques ................................................................................................. 24

6.4.

Industrial vs OIML and NTEP Modes ....................................................................... 24