13

P

anama

®

E

nErgy

s

tar

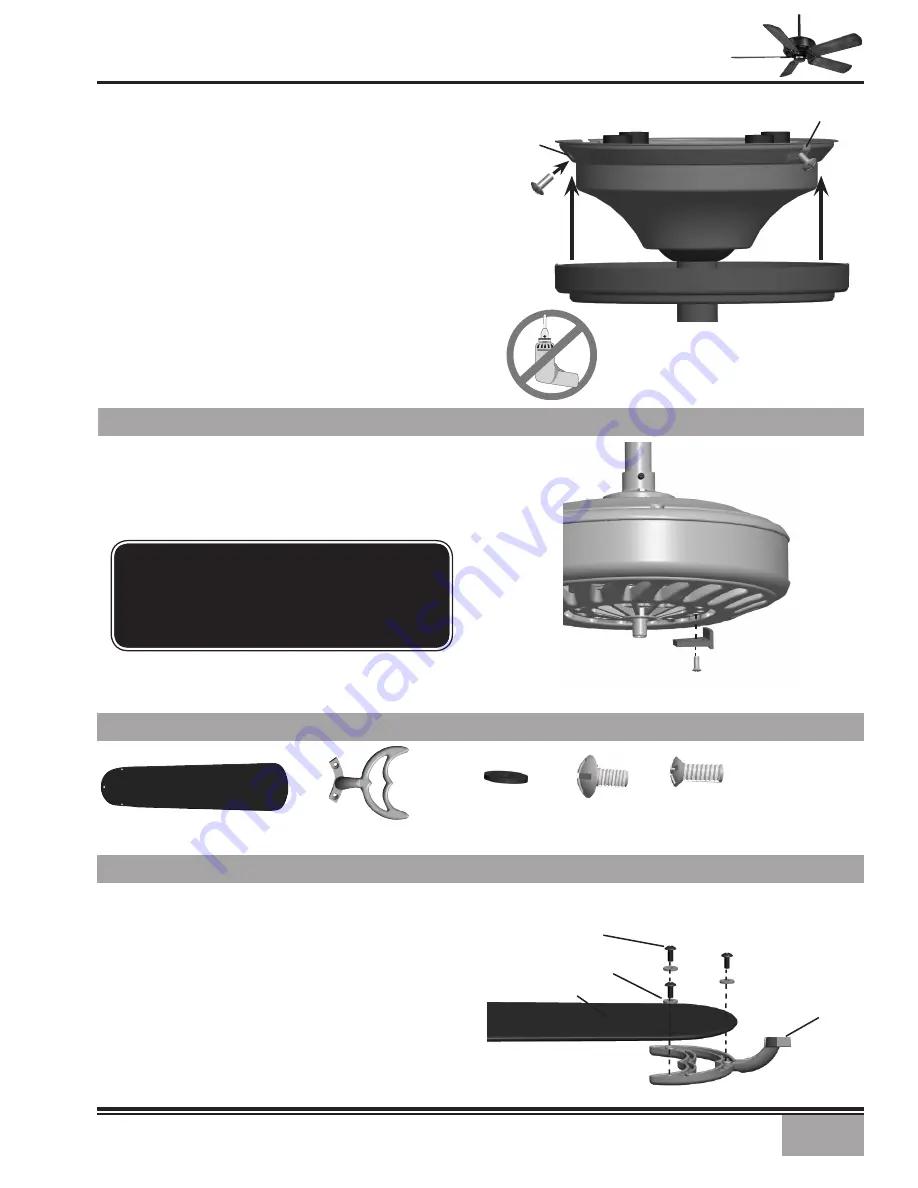

Step 10. Raise the Canopy over the Hanger Bracket.

Align the partially installed screws with the key slots

in the canopy.

Step 11. Twist the Canopy clockwise to secure.

Step 12. Install the third & fourth canopy screws in

the round holes on Canopy. Securely tighten all four

screws.

Step 13. Using both hands, push the Canopy Trim

ring up to the top of the Canopy.

Step 14. Twist the Canopy Trim ring clockwise to

secure it to the Canopy.

Keyhole Slot

Round

Hole

REMOVE SHIPPING BLOCKS

BLADE HARDWARE

BLADE INSTALLATION

Blades (5)

Not Included

Blade Irons (5)

Blade

Screws (16)

Blade Iron

Screws (11)

Step 1. Attach a blade to a blade iron by first

pressing the blade iron onto the blade, then attaching

the blade iron using 3 blade screws and blade

washers as shown in Figure #1. Using a phillips head

screwdriver, tighten securely by hand only. Repeat

for each blade assembly.

Blade

Washers (16)

Blade

Blade Iron

Blade Washers

Blade Screws

Step 1. On the motor, remove the five shipping

blocks by unscrewing the screws. Discard the

shipping blocks.

CAUTION:

Do NOT discard the Blade Iron

Screws. They will be used for

Blade Installation.

FIGURE 1.