10

CAUTION: The Motor Adapter has a special

coating on the threads. Do not remove this

coating; the coating prevents the downrod

from unscrewing. Once assembled, do not

remove the downrod.

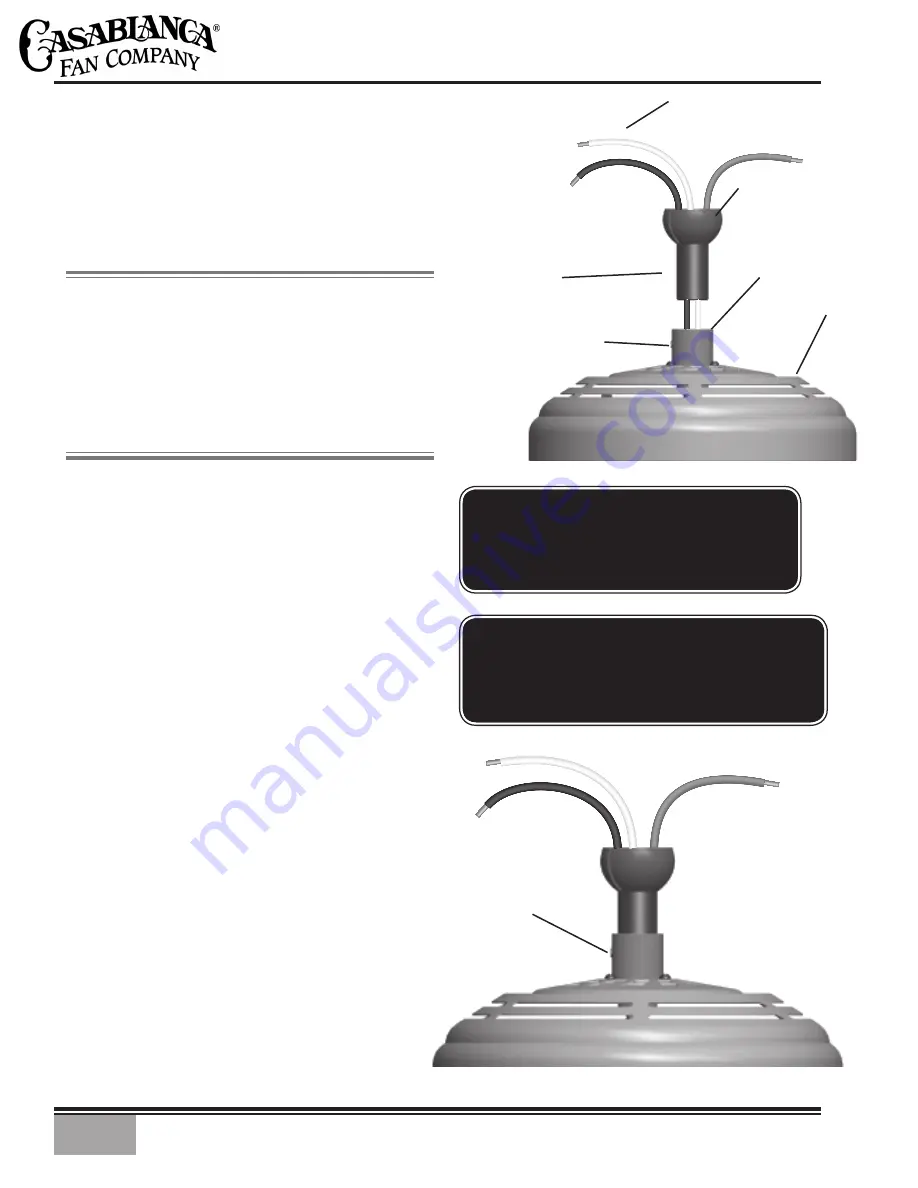

Step 2. Route the wires through the 3"

Perma•Lock downrod and ball assembly as shown

in Figures #3. Insert the downrod into the motor

coupling and turn it clockwise until it stops turning,

ensuring that the pole has bottomed out.

Step 3. Tighten the set screw using the provided

allen wrench.

Tip: The downrod has a tapered thread that

is designed to lock completely when installed

correctly. Tighten the set screw as shown in Figure

#4 with the included allen wrench to ensure

safe operation of your fan. If it is tight enough,

you should not be able to turn the downrod

counterclockwise with your hands. If in doubt,

tighten the set screw until you cannot turn it any

further.

CAUTION: Failure to fully lock in the

downrod before securely tightening the

set screw may cause the fan to separate

from the downrod and fall during normal

operation.

FIGURE 3.

TAPERED

THREAD

MOTOR

COUPLING

MOTOR WIRES

(LEAVE AT LEAST

6" LONG)

PERMA•LOCK™

DOWNROD AND

BALL ASSEMBLY

MOTOR

HOUSING

ASSEMBLY

SET SCREW

Set Screw

FIGURE 4.