ERIODIC MAINTENANCE

P

12

6801202

100-Hour Maintenance

Every time the lift truck is service or every 100 hours of

truck operation, whichever comes first, complete the

following maintenance on the attachment:

Check for loose or missing fasteners, worn or damaged

•

hoses and hydraulic leaks.

Inspect front bin stops for damage. If front stops do not

•

go all the way down, loosen the domed nut jam nuts.

Turn the outer nut CW 1/4 turn. Tighten nuts and test.

Check that the fork pin detent locks when engaged.

•

500-Hour Maintenance

After each 500 hours of truck operation, in addition to the

100-hour maintenance, perform the following procedures.

Inspect tilt cylinder pivot pin retainers. If necessary

•

tighten capscrews to 8–9.5 ft.-lbs. (11–13 Nm).

Inspect the front bin stop rod and bushings for wear.

•

Replace as necessary.

Inspect tilt frame pivot pin and bushings for wear.

•

Replace as necessary. Tighten retainer capscrews to

8–9.5 ft.-lbs. (11–13 Nm).

Verify that the tilt frame rotates to 135

•

°

. If necessary

adjust locknut located underneath the attachment.

1000-Hour Maintenance

After each 1000 hours of truck operation, in addition to

the 100 and 500-hour maintenance, perform the following

procedures.

Inspect lower frame and lift cylinder bearings for

•

wear. Replace as necessary. If the bearing is worn

to less than 3/32 in. (2.5 mm) thickness, replace the

bearing set. Refer to service manual for replacement

procedure.

Inspect lift cylinder cap for wear. Replace as

•

necessary.

WARNING

: After completing any service

procedure, always test each function

through five complete cycles. First test with

no load, then test with a load to make sure

the attachment operates correctly before

returning it to the job.

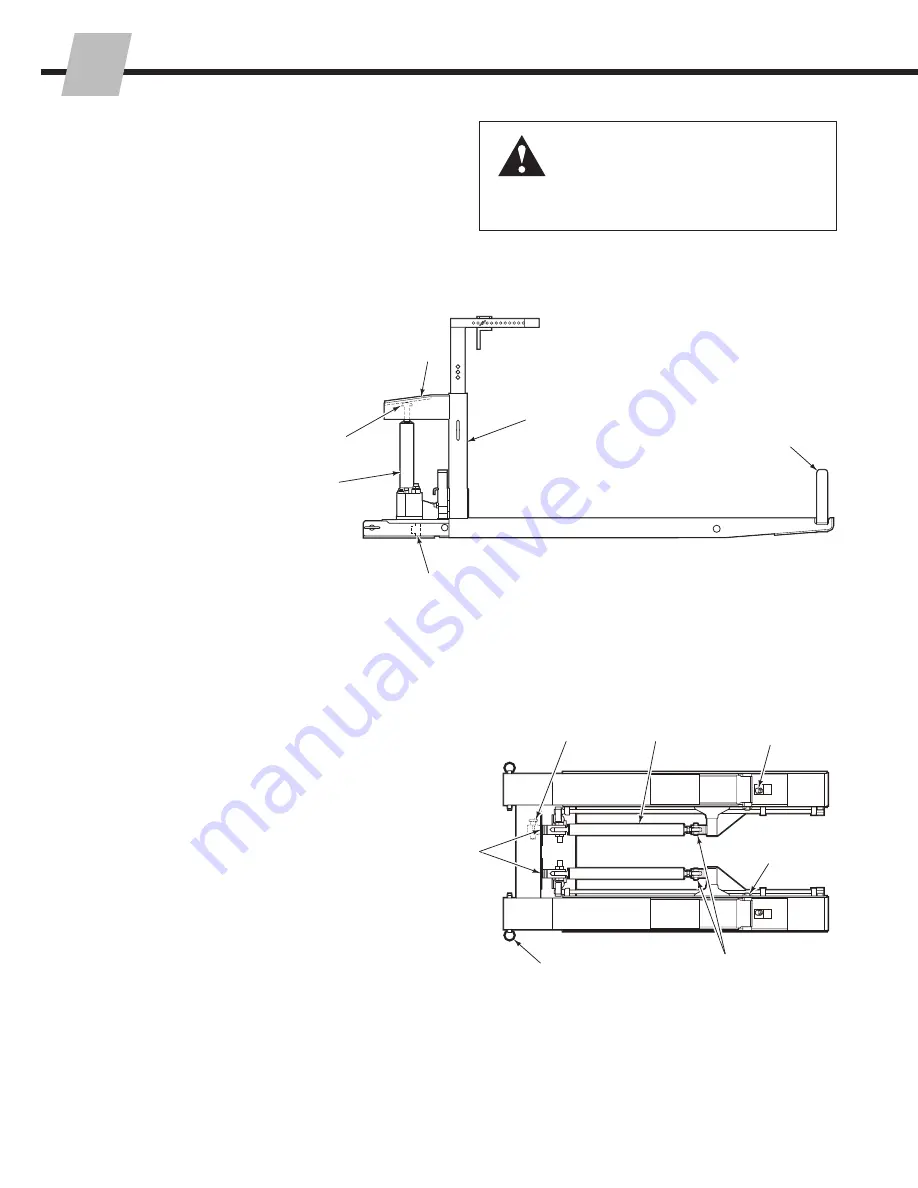

BD0165.eps

BD0166.eps

Bottom View

Side View

Lift

Cylinder

Bearing

Lift Cylinder

Cap

Lift Cylinder

Upper Frame

Assembly

Front Bin

Stops

Lower Frame

Bearing

Bin Stop Rod

and Bushing

Tilt Cylinders

Tilt Frame

Pivot Pins

Cylinder Rod Ends and

Pivot Pin Retainers

Tilt Adjuster

Lock Nut

Fork Pin

Lower

Frame

Bearings