13

6814459-R6 EN

NSTALLATION

I

FP1967.eps

7

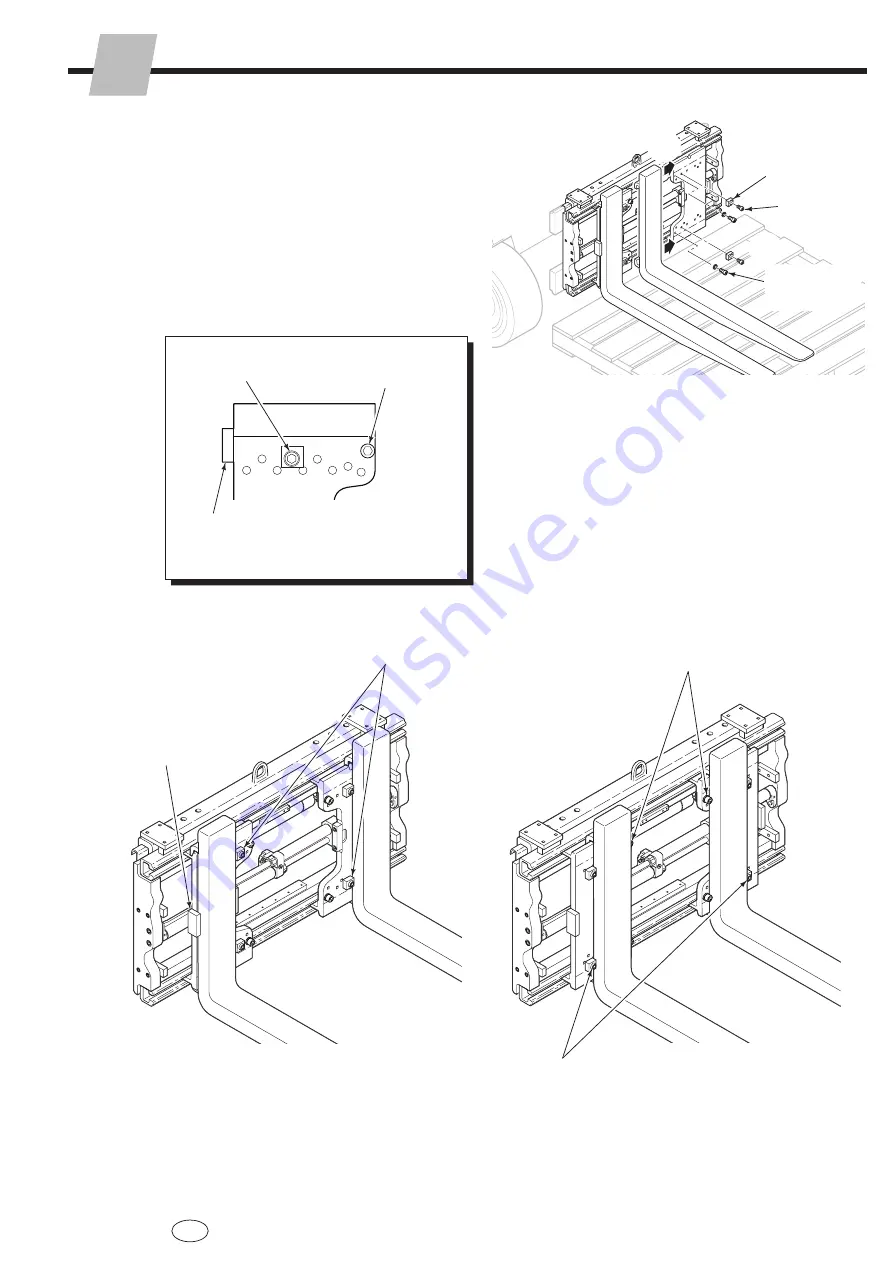

Install forks

A

Remove inner carrier fork stops, retainers and

their hardware.

B

Install forks using a pallet or blocks. Keep feet

clear of forks.

C

Reinstall retainer, its hardware and inner carrier

fork stop capscrews with washers. Tighten

capscrews to

100 Nm.

NOTE:

See illustration below to position

retainers for various widths.

A

B

C

Retainer

Capscrew

Retainer

Inner Carrier Fork

Stop - Capscrew

and Washer

FP2107.eps

FP2108.eps

Install retainers for

minimum clearance

with inside of forks

Install retainers for

minimum clearance

with outside of forks

Position forks

against outer

fork stops

Position forks

against inner

fork stops

FP2109.eps

Retainer

Outer Fork Stop

(nonremovable)

Inner Fork Stop

(removable)

Front View

CAUTION:

Install forks

at minimum In to In

OR

maximum Out to Out

positions only.

MAXIMUM OUT TO OUT

MINIMUM IN TO IN

Summary of Contents for 25L

Page 23: ...BLANK ...