2

684945-R5

PP0124.eps

Introduction

i

Safety Rules

1

Daily Inspection

2

Attachment Operation

2

Slipsheet Loads

3

Loads with Torn Slipsheet Tabs

3

Loading

4

Loading from Floor

4

Loading from Pallets

4

Loading from Stacks

5

Loading from Truck Trailers

5

Unloading

6

Unloading on Stacks

6

Unloading on Pallets

6

Pallet Boards In Line with Push Direction

6

Unloading on Pallets

7

Pallet Boards Opposite Push Direction

7

Unloading into Truck Trailers

7

Sheet-Sav

®

Operation

8

Attachment Removal – QFM™

8

Attachment Installation – QFM™

9

Platen Adjustment

9

Faceplate Stop Adjustment

10

Safe Operation and Maintenance

11

OSHA Regulations

11

C

ontents

WARNING:

Rated capacity of the truck/

attachment combination is a responsibility

of the original truck manufacturer and may

be less than shown on the attachment

nameplate. Consult the truck nameplate.

WARNING:

Do not operate this attachment

unless you are a

trained and authorized

lift truck driver.

i

This guide contains operating instructions for

cascade

35E/45E Load Push/Pulls. It will

help avoid common errors which often cause

damage to the equipment or loads being

handled.

Read this manual thourghly before operating

the attachment. Be sure you know and

understand all operating procedures and safety

precautions. If you have any questions or don't

understand a procedure ask your supervisor.

Emphasize Safety! Most accidents are caused

by operator carelessness or misjudgement.

You must watch for hazardous situations and

correct them.

ntroduction

I

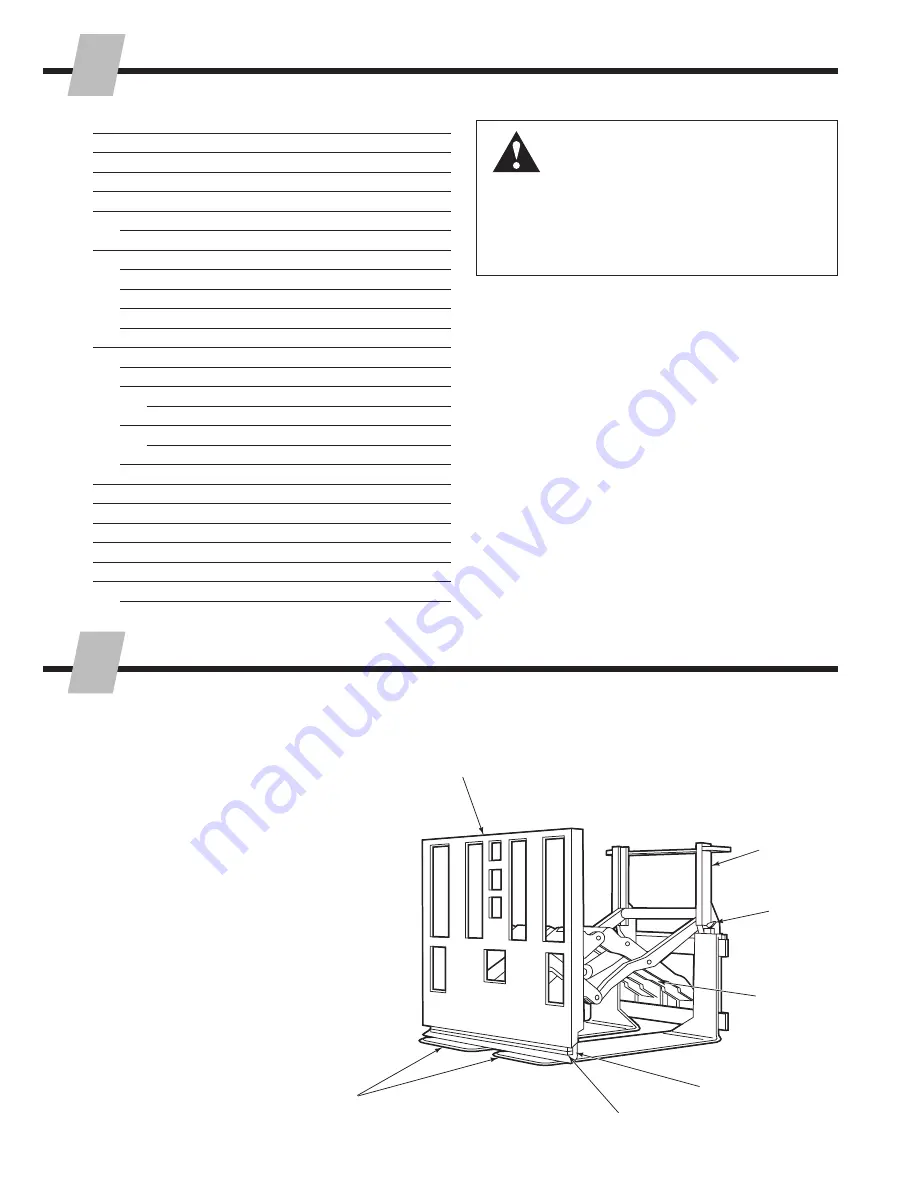

Platens

Faceplate

Frame

Platen

locks

Mechanism

linkage

Gripper bar

Gripper jaw

Summary of Contents for 35E

Page 15: ...BLANK ...