1

6914838 EN

IN0015.eps

INTRODUCTION

This section contains operating instructions for the

Cascade 80R and 100R Integral Sideshifter/Fork

Positioner. It will help you avoid common errors which

often cause damage to the equipment or product

being handled.

This information is intended to simplify operator

understanding about effective and safe Attachment

use and operation. Read this information thoroughly

before operating the attachment. Be sure you know

and understand all operating procedures and safety

precautions. If you have any questions or don’t

understand a procedure, ask your supervisor.

Emphasize Safety!

Most accidents are caused

by operator carelessness or misjudgment. You

must watch for poorly maintained equipment and

hazardous situations and correct them.

Special Definitions

The statements shown appear throughout this Manual

where special emphasis is required. Read all WARNINGS

and CAUTIONS before proceeding with any work.

Statements labeled IMPORTANT and NOTE are provided

as additional information of special significance or to make

the job easier.

CAUTION –

A statement preceded by CAUTION is

information that should be acted upon to prevent

machine damage.

IMPORTANT –

A statement preceded by IMPORTANT is

information that possesses special significance.

NOTE –

A statement preceded by NOTE is information that

is handy to know and may make the job easier.

WARNING

– A statement preceded by

WARNING is information that should be

acted upon to prevent bodily injury. A

WARNING is always inside a ruled box.

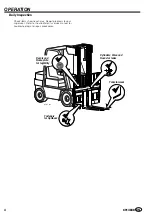

Forks

Backrest

WARNING

: Rated capacity of the truck/

attachment combination is a responsibility

of the original truck manufacturer and may

be less than shown on the attachment

nameplate. Consult the truck nameplate.

WARNING

: Do not operate this attachment

unless you are a trained and authorized lift

truck driver.

OPERATION

Frame

Sideshift

Cylinder

Weighted Emission Sound Pressure Level -

Weighted

emission sound pressure level (L

A) does not exceed 70

dB(A).

Measured Value of Whole Body Vibration -

Measured

value of whole body vibration (m/s2) does not exceed 0,5

m/s2.

Measured Value of Hand-Arm Vibration -

Measured value

of hand-arm vibration (m/s2) does not exceed 2,5 m/s2.

Fork Shaft

Summary of Contents for 100R

Page 17: ...Blank...