6

217521 Rev. 0

10

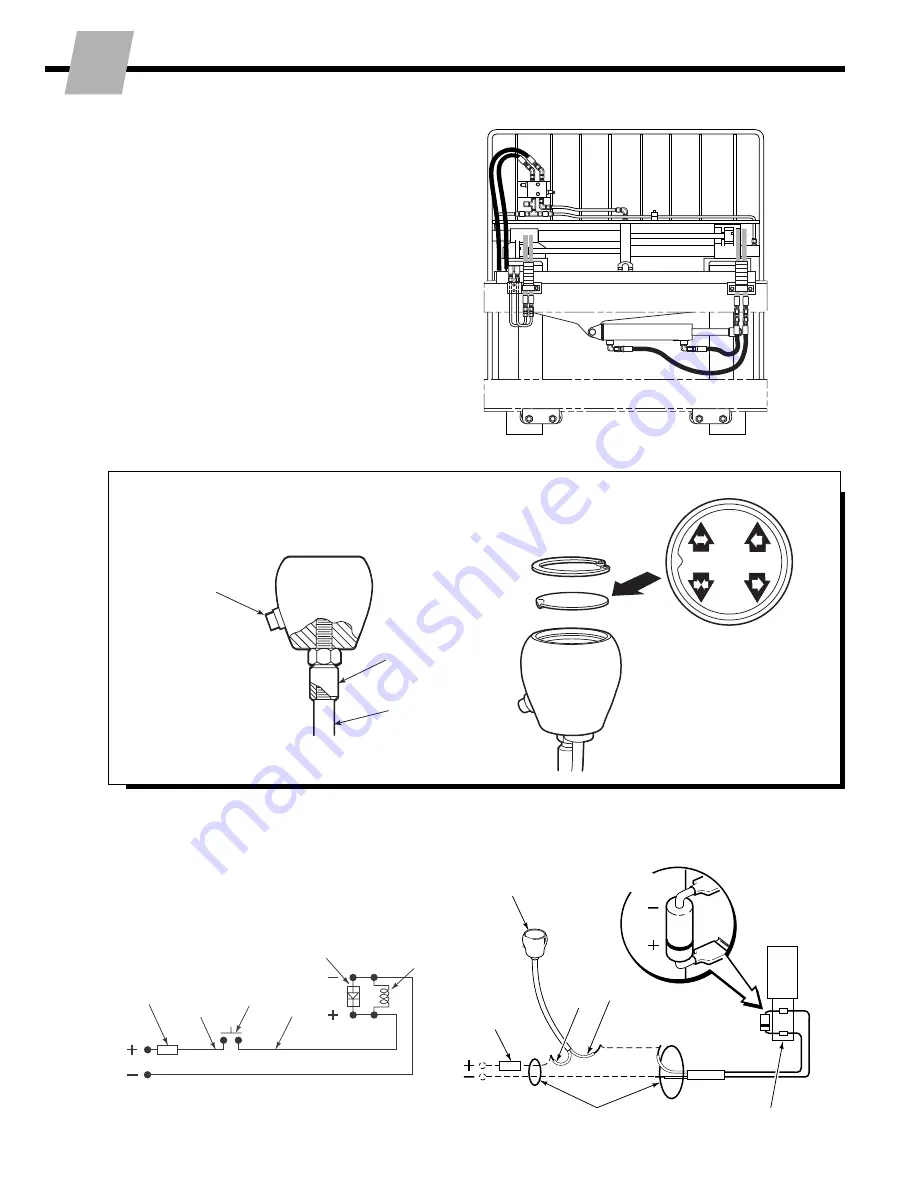

Install wiring –

(Solenoid equipped units)

PRESS

BUTTON

TO POSITION

SIDESHIFT

CL0240.ill

Button

toward

driver

Truck control

valve handle

Adapter

9

Install solenoid control knob –

(Solenoid equipped units)

CL0258.ill

CL0257.ill

Solenoid Coil

User-supplied wire

7.5-Amp

Fuse

White

Black

7.5-Amp Fuse

White

Black

Solenoid Coil

Diode

Diode

Knob

Button

Control Lever Knob

8

Connect hoses prepared in

Step 6 to Attachment fittings

FP0219.ill

I

NSTALLATION