This Manual provides instructions for installing the Cascade

90FX-Series Paper Roll Clamp on lift trucks.

Follow the suggested installation procedures for best

results. If you have any questions or need more information,

contact your nearest Cascade Service Department

(see back cover).

Read the

WARNING

Statements placed throughout this

Manual to emphasize safety during installation.

IMPORTANT:

Field alterations may impair performance or

capability and could result in loss of warranty. Consult

Cascade for any required modifications.

ONTENTS

C

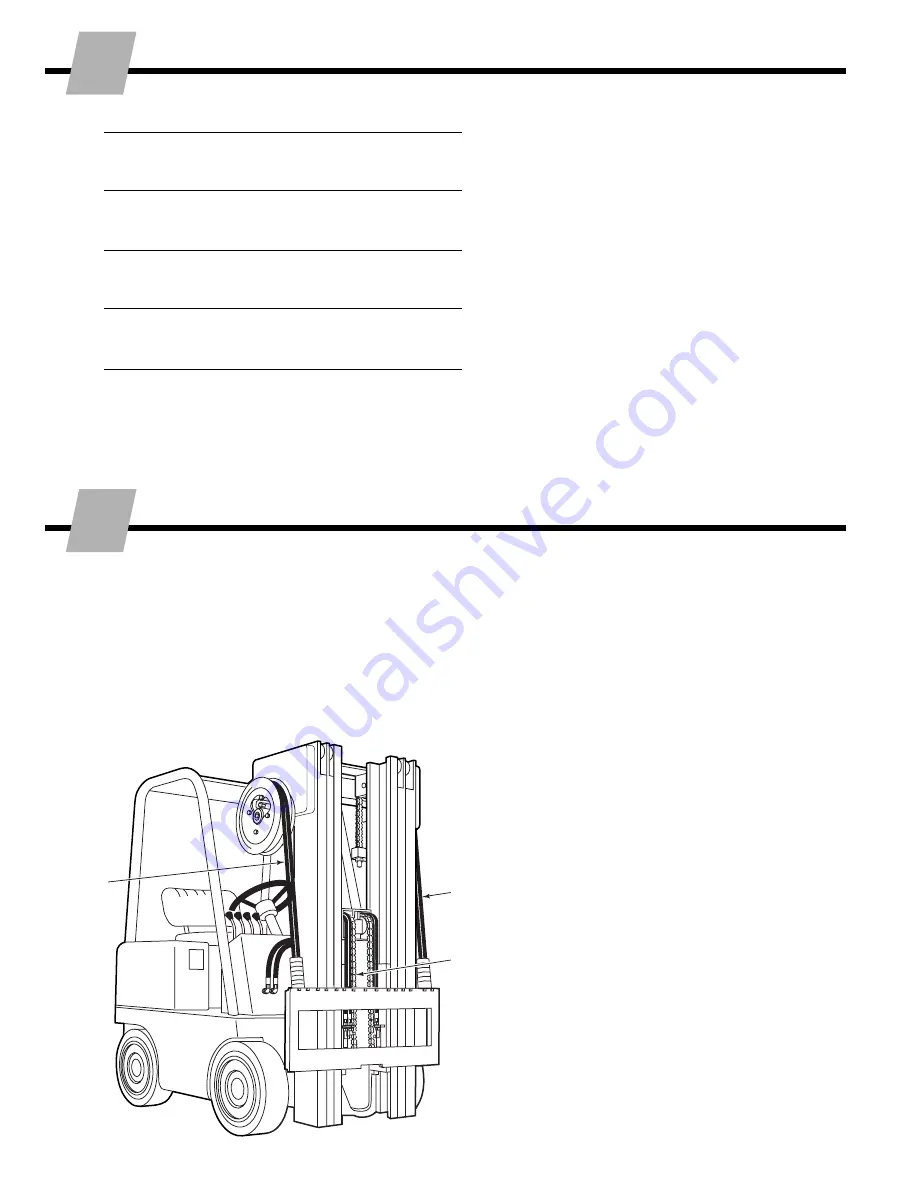

The FX-Series Swing Frame Paper Roll Clamp requires two

(2) hydraulic circuits over the mast to provide three (3)

functions CLAMP, ROTATE and SWING on the Attachment.

No solenoid adaption is required. Recommended hydraulic

supply arrangement is

A and B

, or

C

. Refer to Cascade

Hose and Cable Reel Selection Guide, Part No. 212199, to

select the correct hose reel for the mast and truck. Hose

and fitting requirements are:

• No. 8 with .400 in. (10 mm) minimum I.D. for both CLAMP

and ROTATE/SWING functions.

A and B

RH and LH THINLINE

™

2-Port Hose Reel Groups.

OR

C

Mast Double Internal Hose Reeving Group.

OR (optional)

A or B and C

LH or RH THINLINE™ 2-Port Hose Reel Group and

Mast Single Internal Hose Reeving Group.

B

A

GA0033.ill

C

ECOMMENDED HYDRAULIC SUPPLY

R

i

6028021 Rev. 1

Recommended Hydraulic Supply

i

Truck Requirements

1

Installation

2

Periodic Maintenance

11