RUCK REQUIREMENTS

T

6028021 Rev. 1

1

GA0082.ill

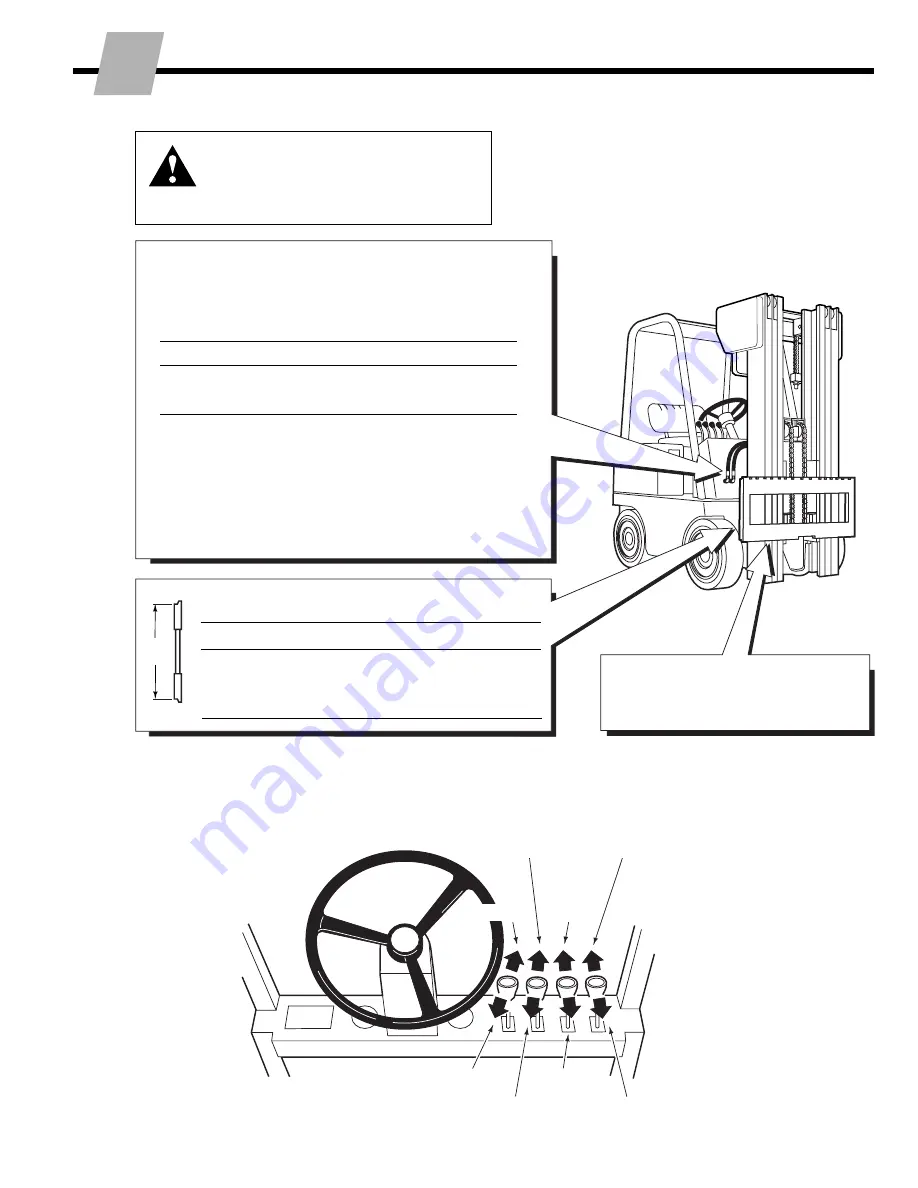

WARNING:

Rated capacity of the truck/

attachment combination is a responsibility of

the original truck manufacturer and may be

less than that shown on the attachment

nameplate. Consult the truck nameplate.

GA0080.ill

Clamp

Rotate

CW

(Swing

Retract)

Tilt

Forward

Hoist Up

Auxiliary Valve Functions

Check for compliance with

ITA (ISO) standards:

Carriage

Clean and inspect carriage bars for

damage and smoothness. Repair any

protruding welds or damaged notches.

Tilt Back

Hoist Down

Release

Rotate

CCW

(Swing

Extend)

Truck Relief Setting

2000 psi (140 bar) Recommended

2300 psi (160 bar) Maximum

Truck Flow Volume

➀

Min.

➁

Recommended

Max.

➂

90FX

12 GPM

15 GPM

20 GPM

(45 L/min.)

(56 L/min.)

(75 L/min.)

➀

Cascade Roll Clamps are compatible with SAE 10W petroleum

base hydraulic fluid meeting Mil. Spec. MIL-0-5606 or MIL-0-

2104B. Use of synthetic or aqueous base hydraulic fluid is not

recommended. If fire resistant hydraulic fluid is required,

special seals must be used. Contact Cascade.

➁

Flow less than minimum will result in a rotate speed less

than 2 RPM.

➂

Flow greater than maximum can result in excessive heating,

reduced system performance and short hydraulic system life.

GA0028.ill

Carriage Mount Dimension (A)

ITA (ISO)

Minimum

Maximum

Class II

14.94 in. (380.0 mm)

15.00 in. (381.0 mm)

Class III

18.68 in. (474.5 mm)

18.74 in. (476.0 mm)

Class IV

23.44 in. (595.5 mm)

23.50 in. (597.0 mm)

A