12

6921954

Table of Torques for ROLLERFORKS®

When ordering components, you are advised to not only look up the product numbers in the appendices but also

to check the measurements of the relevant components yourself. This is because a special version may be involved, in which some

components may vary from the standard version.

Ordering Components

Torques

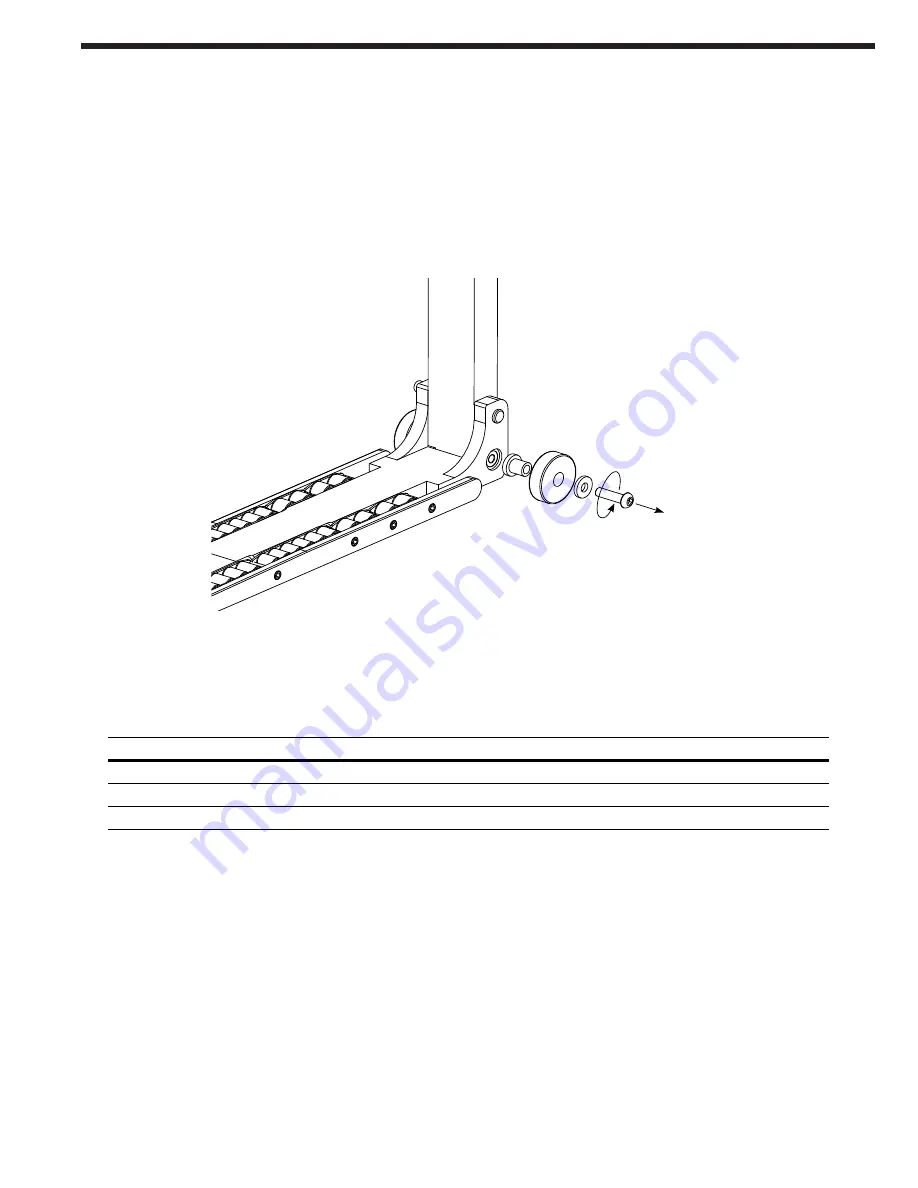

1.

Set the ROLLERFORKS® to hip height and switch off the forklift truck.

2.

Remove the components in accordance with the image below.

3.

Remove the old Loctite and clean the screw thread of the bolt using Loctite 7063 cleaner.

4.

Now apply Loctite 2701 to the bolt.

5.

Fit the new support roller and accompanying parts, and tighten the bolt in accordance with the table Torques for

ROLLERFORKS®.

Instructions for Replacing the Support Rollers

Item

Recommended torque (Nm)

Bolt M8 class 12.9

37

Bolt M10 class 12.9

70

Bolt M16 class 8.8

180