6 - MAINTENANCE

Track tension

WARNING

Tip-over hazard!

Only raise the track as little as necessary.

Failure to comply could result in death or serious injury.

W0276A

Check the track tension every

50 h

NOTICE:

if the tracks are too tight, they wear quickly. If tracks are not tight enough, they wear quickly and can catch

on the sprocket wheel or slide off the idler wheel or the sprocket wheel. Clean the tracks after work.

To check the tracks tension, proceed as follows:

1. Swing the upper structure perpendicular to the un-

dercarriage. Lower the attachment to the ground,

then lower the boom until the track is raised off the

ground. Place a block under the undercarriage and

raise the attachment off the ground.

2. Set the engine speed lever to the maximum speed

position.

3. Operate the travel control lever to move the raised

track forward and backward and shake off the mud.

4. Repeat the same operations for the other track.

SMIL16MEX0422AB

1

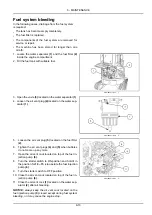

Checking the tension

1.

Stop the engine, then remove the key from the

starter switch.

2.

At the center of the track, measure the slack

(L)

between the bottom of the lower roller

(A)

and the

rubber track shoe

(B)

.

The value must be within

5 – 10 mm

(

0.2 – 0.4 in

).

4.

Adjust the tension as necessary, then lower the

track to the ground.

5.

Repeat the same operations for the other track.

SMIL16MEX0423AB

2

Adjusting the tension

To increase the tension:

1.

Clean the grease fitting adapter and the grease

fitting.

2.

Connect the grease pump. Inject the grease to

obtain the right amount of track tension.

3.

Remove the grease pump and clean the grease

fitting.

4.

Repeat the same operations for the other track.

6-27

Summary of Contents for CX37C

Page 16: ...1 GENERAL INFORMATION 1 10...

Page 64: ...3 CONTROLS AND INSTRUMENTS Footrest SMIL16MEX1264BA 17 3 12...

Page 136: ...5 TRANSPORT OPERATIONS 5 8...

Page 200: ...6 MAINTENANCE 6 64...

Page 204: ...7 TROUBLESHOOTING 7 4...

Page 212: ...8 SPECIFICATIONS 8 8...