19

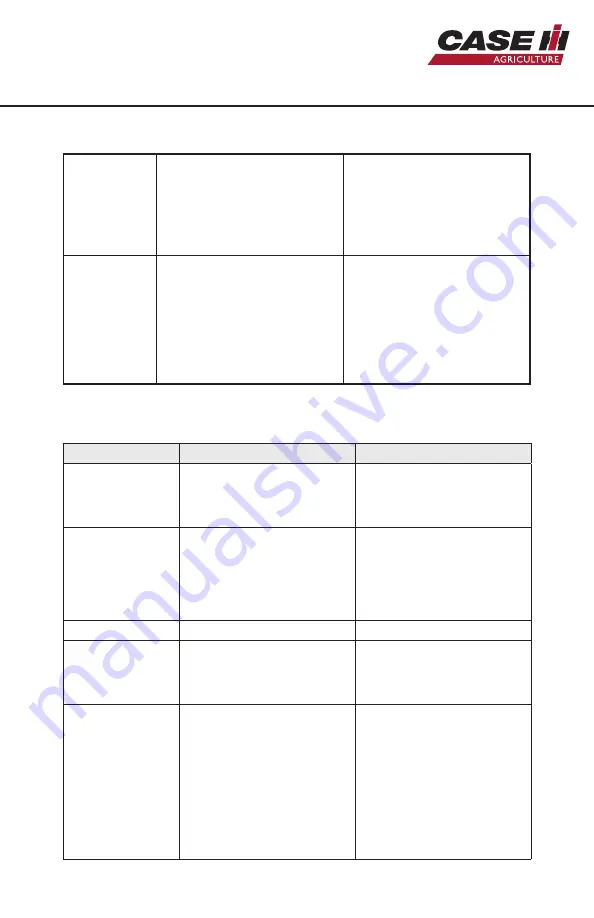

Problem

Possible Cause

Corrective Action

Low Voltage

Engine Speed is too low

Generator is overloaded

Replace or repair engine throttle

Reduce load on generator by

unplugging components

Circuit Breaker Trips Defective load connected to

generator

Defective Receptacle

Generator is overloaded

Disconnect load

Replace the receptacle

Reduce load on generator

Voltage is too high

Engine speed is too high

Reduce engine speed

Unit is over-heating

Generator is overloaded

Insufficient Ventilation

Reduce generator load

Improve air flow in your work-

space

No power output

Disconnect Load

Broken or loose wire

Defective receptacle

Defective stator

Defective rotor

Defective capcitor

Circuit breaker tripped

Disconnect load

For any defective components,

have the generator inspected by

a certified technician

Reset the circuit breaker

Generator

tROubLeshOOtING

Compressor

won’t start in

cold weather

1. Bad check valve.

2. Compressor has the wrong

grade of oil.

3. Control lines frozen.

1. Use IS 100 (30W) compressor

oil for cold weather conditions.

2. Move compressor to a warmer-

location.

3. Put a heat lamp on compres-

sor to maintain above freezing

temperatures.

Compressor

is vibrating

excessively

1. Compressor is not properly

mounted on vibration isolation

pads.

2. Compressor pulley is out of

alignment.

3. Engine is low on fuel of throttle

is out of adjustment.

1. Properly mount compressor on

vibration isolation pads.

2. Re-align pulleys.

3. Check drive engine oil and fuel

level.

4. Re-adjust engine throttle con-

trol (bull whip).