INTRODUCTION

Torque

NOTE:

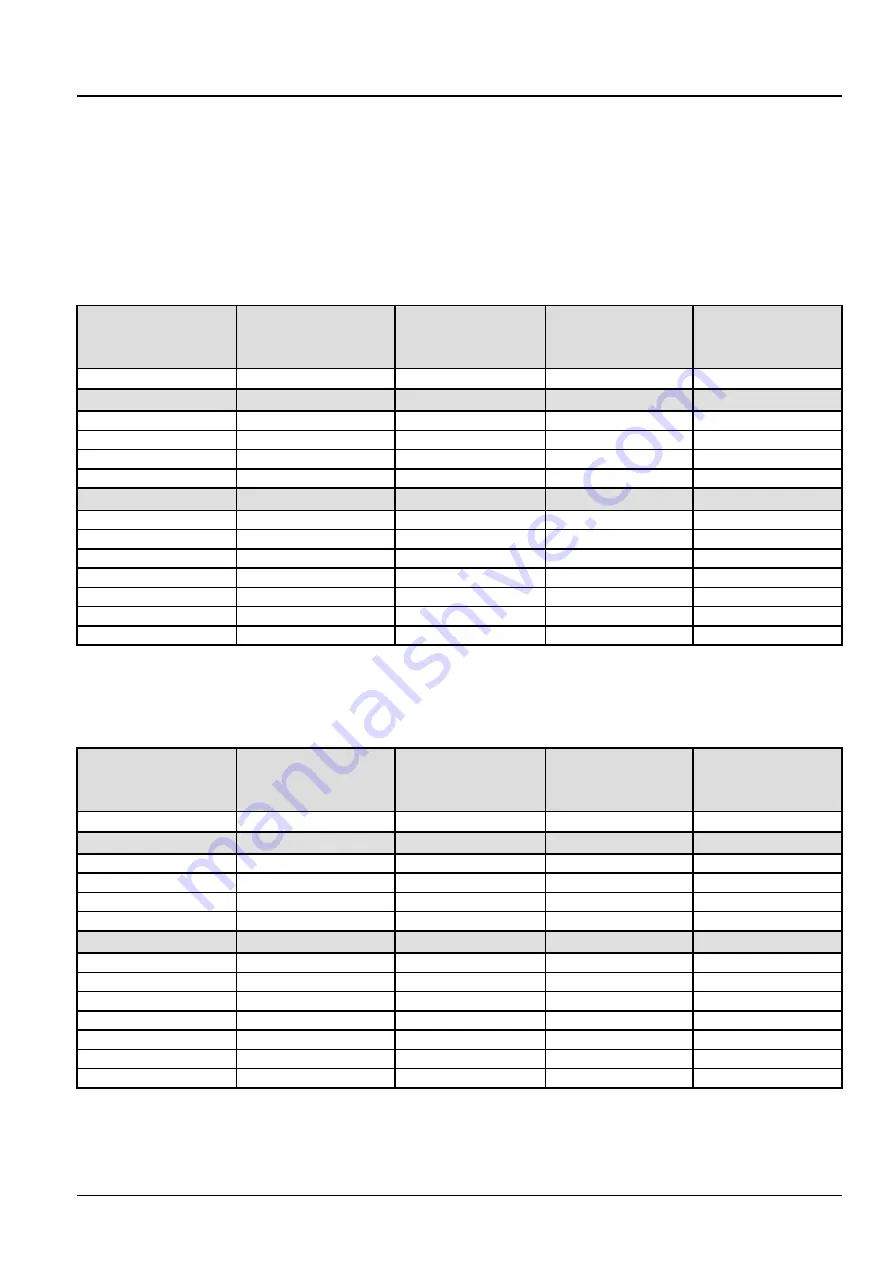

In the metric tables, nominal sizes M4 through M8 hardware torque specifications are shown as a Newton

meters (pound-inches) numerical value.

Nominal sizes M10 through M24 hardware torque specifications are shown as a Newton meters (pound-feet) numer-

ical value.

Metric hex head (non-flange) hardware

Plain (PLN) – an unplated hardware finish with residual manufacturing oils

Zinc-dichromate (ZND) – a yellow colored chemical plating formula yellow applied to the hardware

Nominal size

Class (CL) 8.8

bolt and Class

(CL) 8 nut

Class (CL) 10.9

bolt and Class

(CL) 10 nut

Locknut

CL 8

w/CL 8.8 bolt

Locknut

CL 10

w/CL 10.9 bolt

PLN and ZND

PLN and ZND

ZND

ZND

N·m (lb in)

N·m (lb in)

N·m (lb in)

N·m (lb in)

M4

3.5 (31)

5.0 (44)

1.4 (13)

2.8 (25)

M5

7.0 (62)

10 (88)

2.9 (26)

5.5 (49)

M6

11.8 (104)

17 (150)

4.9 (43)

9.4 (83)

M8

28.8 (255)

41.3 (366)

11.9 (105)

23 (204)

N·m (lb ft)

N·m (lb ft)

N·m (lb ft)

N·m (lb ft)

M10

57 (42)

82 (60)

24 (17)

45 (33)

M12

100 (74)

143 (105)

41 (30)

79 (38)

M14

159 (117)

227 (168)

66 (48)

125 (92)

M16

248 (183)

354 (261)

102 (75)

195 (144)

M18

352 (260)

487 (359)

145 (107)

268 (198)

M20

500 (369)

690 (509)

206 (152)

380 (280)

M24

865 (638)

1195 (882)

357 (263)

657 (485)

Metric flange head hardware

Plain (PLN) – an unplated hardware finish with residual manufacturing oils

Zinc-dichromate (ZND) – a yellow colored chemical plating formula yellow applied to the hardware

Nominal size

Class (CL) 8.8

bolt and Class

(CL) 8 nut

Class (CL) 10.9

bolt and Class

(CL) 10 nut

Flange locknut

CL 8

w/CL 8.8 bolt

Flange locknut

CL 10

w/CL 10.9 bolt

PLN and ZND

PLN and ZND

ZND

ZND

N·m (lb in)

N·m (lb in)

N·m (lb in)

N·m (lb in)

M4

3.8 (34)

5.5 (49)

4.2 (37)

6.1 (54)

M5

7.7 (68)

11 (97)

8.5 (75)

12 (106)

M6

13 (115)

18.7 (166)

14.3 (127)

20.6 (182)

M8

31.7 (281)

45.5 (403)

35 (310)

50 (443)

N·m (lb ft)

N·m (lb ft)

N·m (lb ft)

N·m (lb ft)

M10

63 (47)

90 (66)

69 (51)

99 (73)

M12

110 (81)

157 (116)

121 (89)

173 (128)

M14

175 (129)

250 (184)

193 (142)

275 (202)

M16

272 (201)

389 (287)

299 (221)

428 (316)

M18

387 (286)

535 (395)

426 (315)

589 (435)

M20

550 (406)

759 (560)

605 (447)

835 (616)

M24

951 (702)

1315 (970)

1046 (772)

1447 (1067)

48193161 30/11/2017

9

Summary of Contents for OPTUM 270 CVT

Page 9: ...48193161 30 11 2017 Find manuals at https best manuals com...

Page 10: ...INTRODUCTION 48193161 30 11 2017 1 Find manuals at https best manuals com...

Page 33: ...INTRODUCTION 48193161 30 11 2017 24...

Page 81: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...