INTRODUCTION

Consumables Lubrications and Coolants

Lubrications

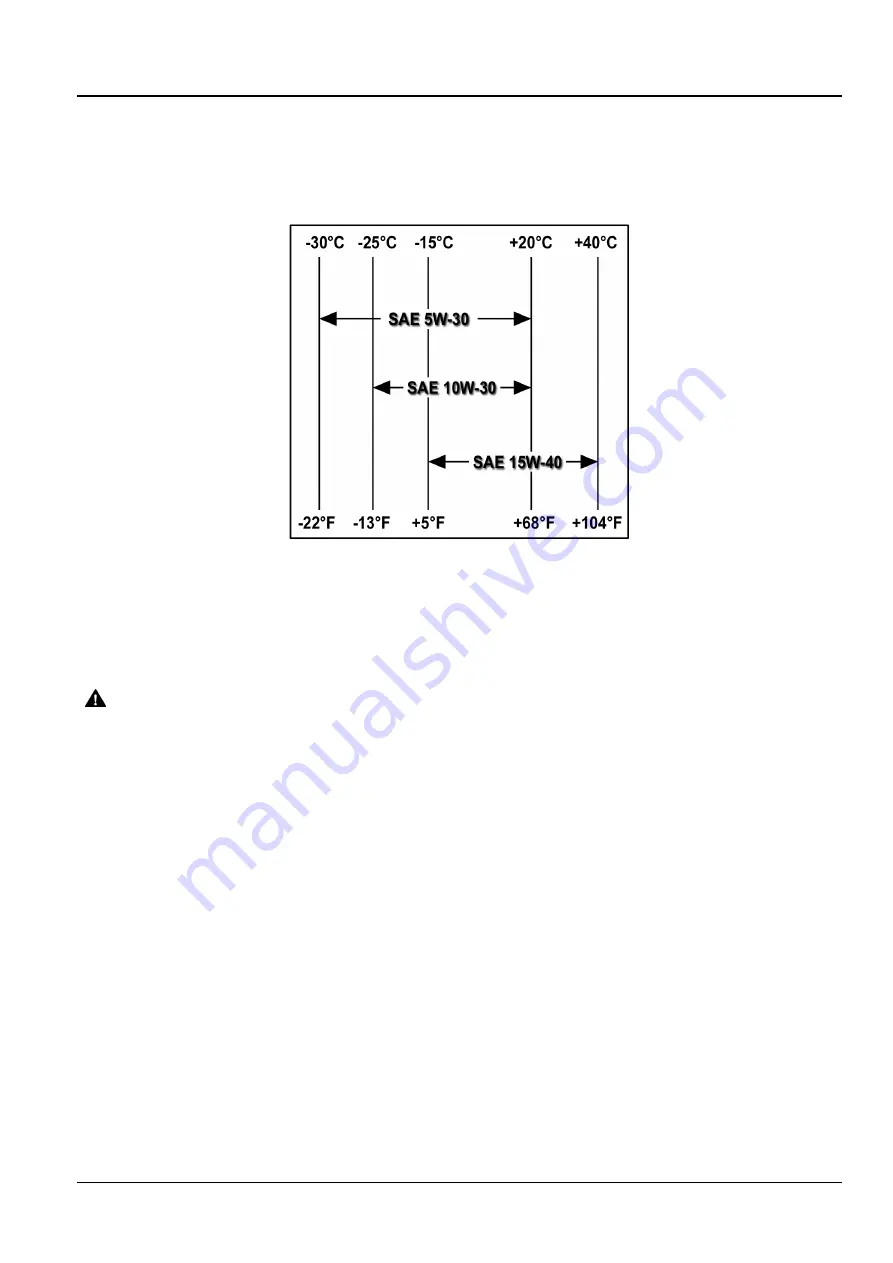

The correct engine oil viscosity grade is dependent upon ambient temperature. Refer to the chart when selecting oil

for your tractor engine.

SS09J076

1

NOTE:

In areas where prolonged periods of extreme temperatures are encountered, local lubricant practices are

acceptable; such as the use of

SAE 5W-30

in extreme low temperatures or

SAE 50

in extreme high temperatures.

The

CASE IH AKCELA TSM BIO

oil is available from your authorised dealer.

Biodegradable Transmission and Hydraulic Oil

WARNING

Burn hazard!

Be very careful to avoid contact with hot fluids. If fluid is extremely hot, allow it to cool to a moderately

warm temperature before proceeding.

Failure to comply could result in death or serious injury.

W0362A

A biodegradable oil has been approved for use in the transmission, 4WD front axle and hubs, and the hydraulic system

of your tractor. Although the oil is

90 %

biodegradable, it is important to follow safe handling and disposal practices.

Biodegradable oil should not be used in conjunction with other oils. Use the following procedure to replace standard

oil with biodegradable lubricant.

1.

Operate the tractor until the oil that is being changed reaches a temperature greater than

60 °C

(

140 °F

).

2.

Stop the engine and immediately drain the oil.

3.

Replace all transmission and hydraulic filters.

4.

Add the biodegradable oil to the correct level and run the tractor to circulate the oil.

5.

Check for oil leaks and recheck the oil level.

Sulphur in Fuel

The engine oil and filter change period are shown in the Lubrication and Maintenance in the operators manual. How-

ever, locally available fuel may have a high sulphur content, in which case the engine oil and filter change period

should be adjusted as follows:

84479138A 06/06/2011

19

Summary of Contents for PUMA 130

Page 4: ...84479138A 06 06 2011 Find manuals at https best manuals com...

Page 5: ...INTRODUCTION 84479138A 06 06 2011 1 Find manuals at https best manuals com...

Page 19: ...INTRODUCTION ZEIL06CS0136F0A 2 ZEIL06CS0135F0A 3 84479138A 06 06 2011 15...

Page 26: ...INTRODUCTION 84479138A 06 06 2011 22...

Page 61: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...