7 - MAINTENANCE

Coolant reservoir (deaeration reservoir) fluid level

Check the deaeration reservoir fluid level every 50 hours

of operation.

1.

To ensure an accurate level reading:

A.

Park the machine on level ground.

B.

Shut down the engine.

C.

Allow time for the coolant to completely cool.

Coolant must be cold before proceeding.

2.

Check the coolant level on the reservoir. The coolant

level should be between the HOT MAX mark

(1)

and

the COLD MIN mark

(2)

.

RAIL11TLB0006AA

1

CAUTION

Burn hazard!

Hot coolant can spray out if you remove the

filler cap while the system is hot. After the sys-

tem has cooled, turn the filler cap to the first

notch and wait for all pressure to release be-

fore proceeding.

Failure to comply could result in minor or mod-

erate injury.

C0043A

3.

Add coolant as needed. Open the filler cap by slow-

ing turning the cap counter-clockwise until it is re-

moved. It is not necessary to remove the hoses in

order to remove the cap.

RCPH11TLB036BAD

2

7-47

Summary of Contents for 570NXT

Page 8: ......

Page 24: ...1 GENERAL INFORMATION 1 16 ...

Page 88: ...3 CONTROLS INSTRUMENTS 3 28 ...

Page 142: ...6 WORKING OPERATIONS 6 34 ...

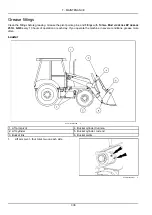

Page 193: ...7 MAINTENANCE Cylinder closed end Two total one on each side RCPH10TLB258AAF 3 7 51 ...

Page 252: ...7 MAINTENANCE 7 110 ...

Page 257: ...8 SPECIFICATIONS Machine overall dimensions 8 5 ...

Page 259: ...8 SPECIFICATIONS RAIL12UTL0182GA 1 8 7 ...

Page 260: ...8 SPECIFICATIONS 8 8 ...

Page 262: ...8 SPECIFICATIONS RAIL12UTL0182GA 2 8 10 ...

Page 272: ...9 ACCESSORIES 9 4 ...

Page 279: ......