INTRODUCTION

Installation of adjustable O-Ring Bosses (ORB) connectors

Adjustable port connectors are commonly found on

shaped connectors, which allow for orientation of the

connection. Adjustable port connectors utilize a locknut

and back-up washer.

NOTICE:

Teflon coated O-rings do not require lubrication.

For connections which are made into aluminum manifolds

or with stainless steel connectors, it may be required to

apply a lubricant to prevent galling.

1. Remove protective connector caps only immediately

prior to assembly.

2. Inspect the components to ensure that the male and

female port threads and sealing surfaces are free of

burrs, nicks, and scratches, or any foreign material.

Do not use if impurities are found.

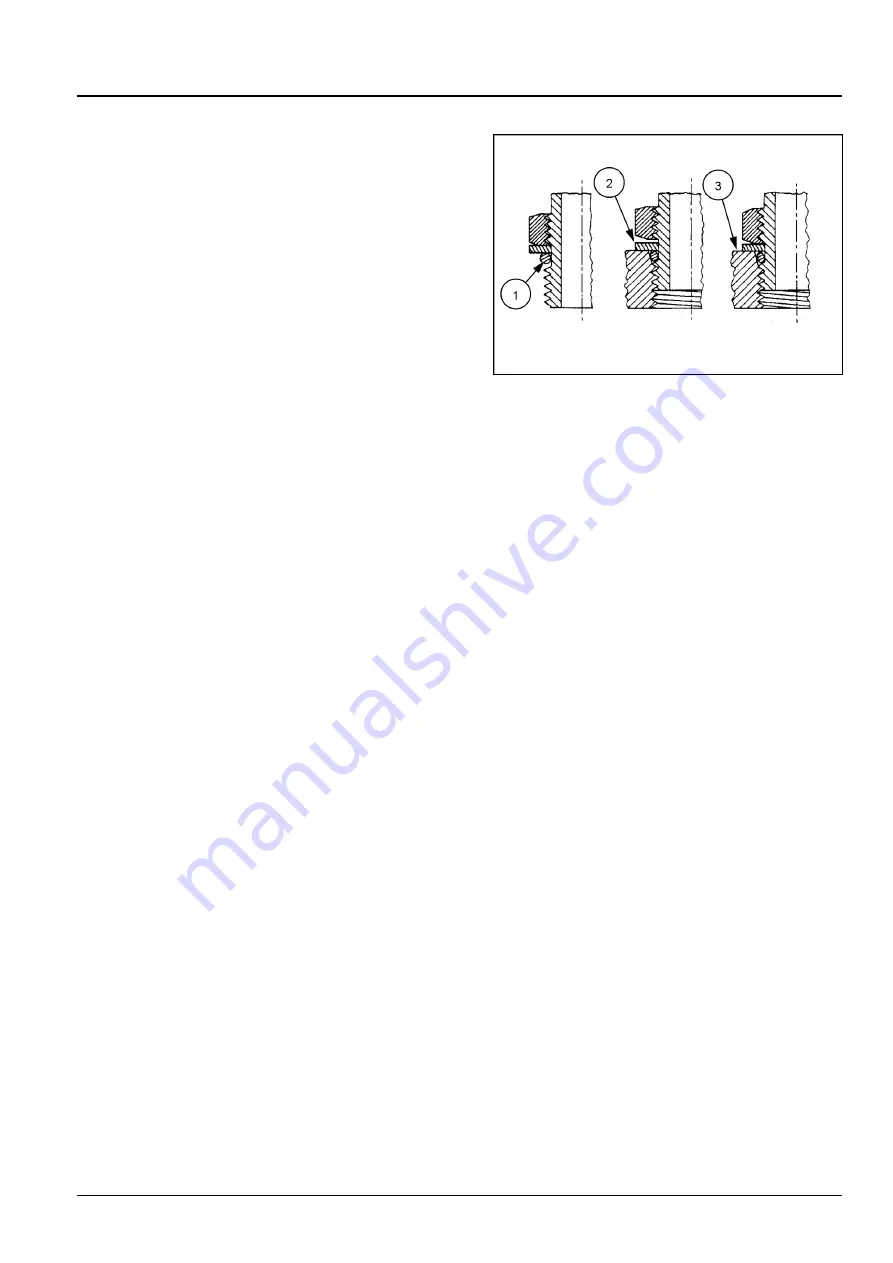

3. Make sure the washer

(2)

is on the fitting before the

O-ring

(1)

.

4. Back off the lock nut as far as possible. Make sure that

the back-up washer is not loose and it is as far up on

the connector as possible.

5. Screw the connector into the port until the back-up

washer

(2)

or the retaining ring contacts the face of

the port

(3)

. Light wrenching may be necessary.

6. Unscrew the connector until you achieve the correct

angle of the connector. Do not unscrew the connector

more than one full turn.

NOTICE:

Do not over tighten the connector you may

damage the washer and increase the possibility of a

leak to occur.

7. Using two wrenches, hold the position of the connector

and tighten the locknut to the proper torque value. See

the torque tables for the proper torque value.

NOTICE:

Make sure that the O-ring is not pinched and

that the washer is seated flat on the face of the port.

Do not over tighten and distort the back-up washer.

23085659

1

48194558 20/10/2017

57