INTRODUCTION

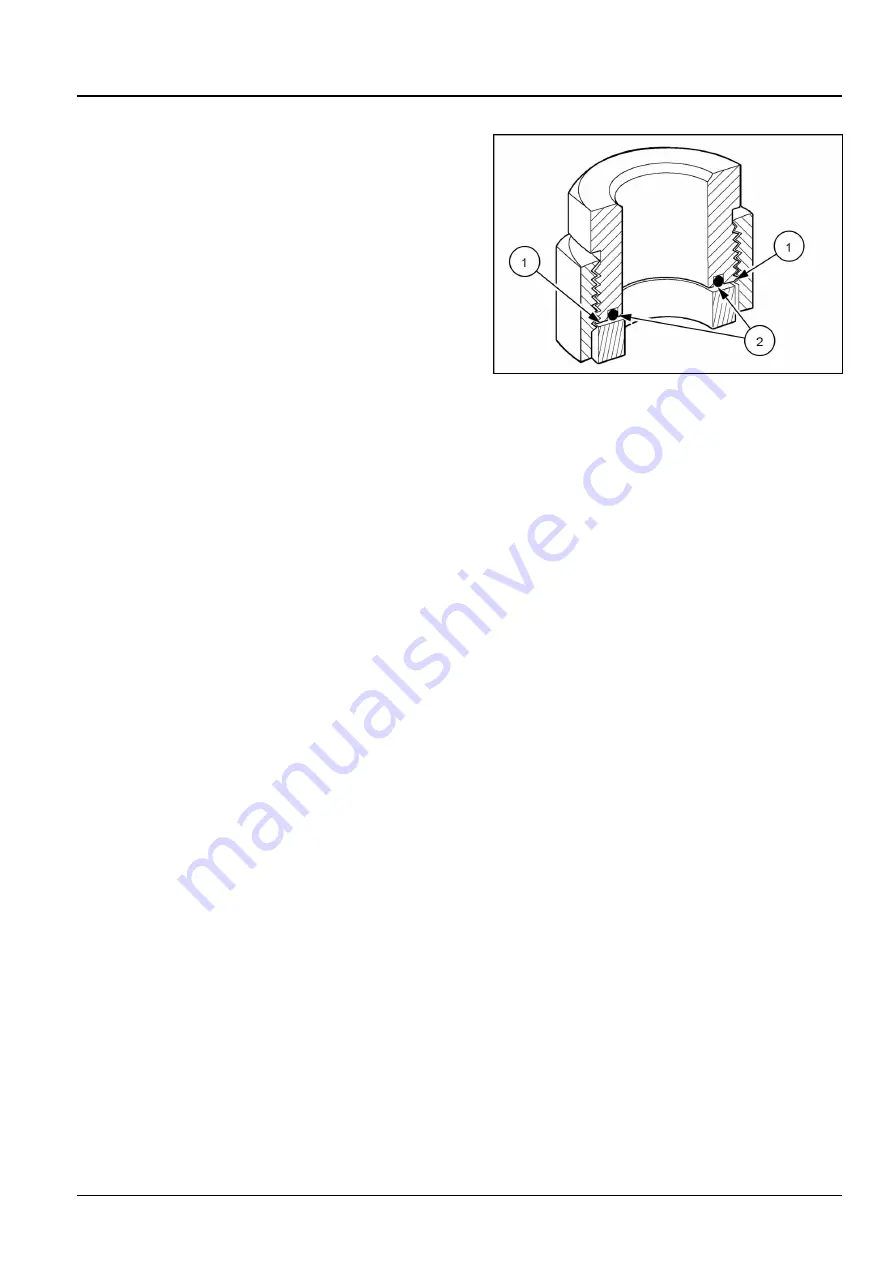

Installation of O-Ring Face Seal (ORFS) connections

1. Remove protective connector caps only immediately

prior to assembly.

2. Inspect the components to ensure that the male and

female threads and sealing surfaces are free of burrs,

nicks, and scratches, or any foreign material. Do not

use if impurities are found.

3. Check that the seal is properly installed in the groove

on the male connector. If the seal is not pre-installed

on the connector body, it must be installed using an

assembly tool:

A. Position the O-ring inside the assembly tool,

against the plunger.

B. Position the tool over the ORFS male end until it is

against the bottom of the tool.

C. Push the plunger of the tool until the O-ring is fully

seated into the groove on the connector.

4. Place the face of the female connector against the face

and O-ring of the male connector.

50011183

5

5. Thread the nut completely onto the male connector by

hand.

6. Complete steps 1 through 5 for both ends of the hose

or tube before continuing.

7. Hand-tighten any clamps that hold the position of the

hose or tube.

8. Tighten the ORFS connection to the proper torque

value. See the torque tables for the proper torque

value.

9. Complete tightening of any clamps that hold the hose

or tube only after both end fittings have been fully tight-

ened.

48194558 20/10/2017

61