7 - MAINTENANCE

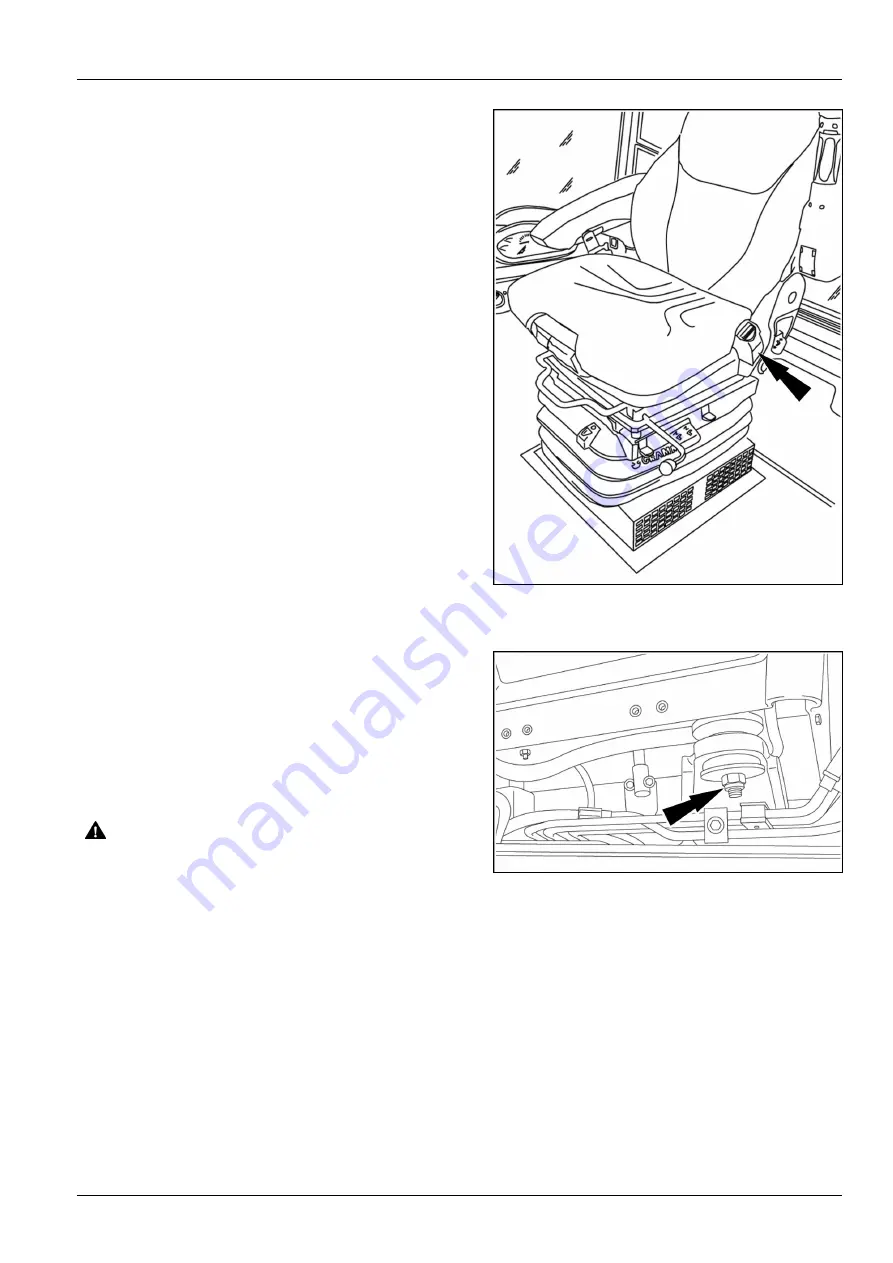

1. Check and inspect the ROPS/FOPS structure and the

seat restraint system every

500 h

of operation.

2. Before you operate this machine, always make sure

the ROPS/FOPS and operator’s seat belt is correctly

installed.

3. The seat belt is an important part of the ROPS/FOPS.

You must wear the seat belt at all times when you op-

erate the machine.

4. Make sure all hardware that secures the seat to the cab

is properly torqued. Make sure all seat belt hardware

is secure and torqued.

5. Torque seat belt hardware to

73 - 87 N·m

(

53.8 - 64.2 lb

ft

).

6. Keep seat belts away from objects that can damage the

seat belts.

7. Keep the seat belts clean. Wash the seat belts only in

soap and water. Do not put the seat belts in bleach or

dye. This will weaken the seat belt.

LEEN11T0001BA_1

2

Torque specifications for ROPS cab

Check the torque of the mounting bolts for the ROPS

canopy and the ROPS cab during the run-in period of

a new machine, as well as at the

500 h

maintenance

interval.

8. Check for cracks, rust, or holes in the ROPS and ROPS

components. Age, weather, and accidents can cause

damage to the ROPS and ROPS parts. If you have any

doubt about the integrity of the ROPS system, see your

CASE CONSTRUCTION Dealer.

WARNING

Tip-over hazard!

Adding additional weight (buckets, attach-

ments, etc.) to the machine can create a tipping

hazard. Do not exceed the gross weight indi-

cated by the machine specifications.

Failure to comply could result in death or seri-

ous injury.

W0153A

9. Check the torque of the ROPS mounting bolts. If nec-

essary, tighten the bolts to the correct torque.

LEEN11T0377AA

3

Torque specifications

ROPS cab mounting bolts (both sides)

Torque to:

180 N·m

(

132 lb ft

).

Seat mounting bolts

Torque to:

73 - 87 N·m

(

53.8 - 64.2 lb ft

).

NOTE:

Torque specifications are for clean, dry threads.

7-41

Summary of Contents for 580ST

Page 8: ......

Page 24: ...1 GENERAL INFORMATION 1 16 ...

Page 49: ...2 SAFETY INFORMATION Extend telescopic dipper If fitted MOLI12LBB0092AA 24 2 25 ...

Page 101: ...3 CONTROLS AND INSTRUMENTS Setup menu LEIL12TLB00006I 1 3 39 ...

Page 144: ...3 CONTROLS AND INSTRUMENTS 3 82 ...

Page 164: ...4 OPERATING INSTRUCTIONS 4 20 ...

Page 166: ...5 TRANSPORT OPERATIONS RAIL14TLB1181GA 1 5 2 ...

Page 222: ...6 WORKING OPERATIONS 6 44 ...

Page 247: ...7 MAINTENANCE Fuel tank capacity 145 L 38 30 US gal 2WS 124 L 32 76 US gal 4WS 7 25 ...

Page 347: ...7 MAINTENANCE Fuses and relays Powershift cab 2WS MOLI12LBB0491CA 7 7 125 ...

Page 349: ...7 MAINTENANCE Fuses and relays Powershift cab 4WS MOLI12LBB0492CA 8 7 127 ...

Page 390: ...8 TROUBLESHOOTING 8 28 ...

Page 418: ...9 SPECIFICATIONS 4WS LEEN11T0039FA 2 9 28 ...

Page 420: ...9 SPECIFICATIONS 2WS 590ST LEEN11T0041FA 5 4WS 695ST LEEN11T0042FA 6 9 30 ...

Page 433: ......