7 - MAINTENANCE

Organic Acid Technology (OAT) coolant

Depending on the date of manufacture, your cooling system may be equipped with conventional ethylene glycol

coolant such as

CASE AKCELA PREMIUM ANTI-FREEZE

or an Organic Acid Technology (OAT) coolant solution

such as

CASE AKCELA ACTIFULL™ OT EXTENDED LIFE COOLANT

. You can easily identify

CASE AKCELA

ACTIFULL™ OT EXTENDED LIFE COOLANT

by its yellow color. You should never mix the coolant types.

NOTE:

Organic Acid Technology (OAT) appears yellow in small quantities. OAT coolant can also appear yellow when

against translucent backgrounds. However, under certain lighting conditions and backgrounds, such as looking into

the coolant overflow tank, OAT coolant may appear green. The green appearance is similar to the color of ethylene

glycol coolant. This color appearance is normal, which is not an indication of mixed coolant fill in new units built after

the implementation of OAT coolant.

The coolant solution used must meet the following CNH

Industrial material specifications for either coolant type:

•

MAT3624

for OAT coolant

•

MAT3620

for conventional coolant

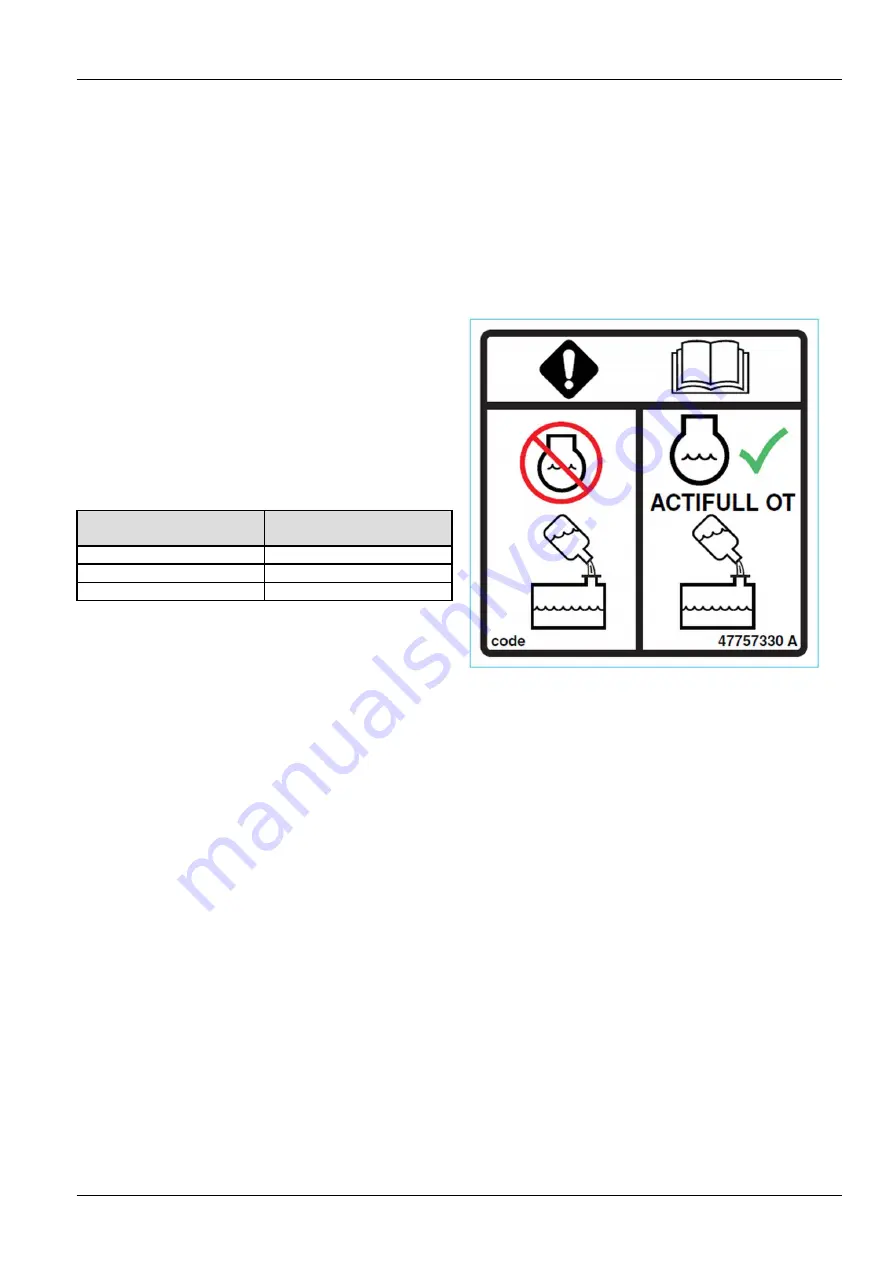

The decal shown is located near the fill point of the cooling

system whenever the factory fill is

CASE AKCELA ACT-

IFULL™ OT EXTENDED LIFE COOLANT

. This decal is

available in three different sizes. See the table below for

the associated part numbers.

CNH Industrial part

number

Size

47757330

50 mm

x

50 mm

47757331

75 mm

x

75 mm

47757332

100 mm

x

100 mm

47757330

1

NOTICE:

NEVER mix OAT coolant with conventional coolant. Under no circumstances should you top off a cooling

system with only water. You can use a refractometer to check the concentration level. You should not use Supplemen-

tal Coolant Additives (SCA) when using

CASE AKCELA ACTIFULL™ OT EXTENDED LIFE COOLANT

. Change the

coolant solution at the change interval recommended.

If you need to change a machine from conventional coolant to OAT coolant or vice versa, you should follow the

“Changing coolant types” procedure below to attain the full benefit of the coolant.

Changing coolant types

To change coolant from OAT coolant to conventional coolant (or vice versa):

1. Empty the engine cooling system by draining the coolant into a suitable container.

2. Fill the system with clean water.

3. Start the engine and run the engine for at least

30 min

.

NOTE:

Make sure that you activate the heating system (if equipped) to circulate fluid through the heater core.

4. Repeat Steps 1 to 3 for a total of two washes.

5. Fill the system with conventional coolant (or OAT coolant).

6. Operate the engine until it is warm. Inspect the machine for leaks.

7. If you are changing to OAT coolant, then attach the decal (CNH Industrial part number 47757330) to indicate the

use of OAT coolant in the cooling system.

7-9

Summary of Contents for 580ST

Page 8: ......

Page 24: ...1 GENERAL INFORMATION 1 16 ...

Page 49: ...2 SAFETY INFORMATION Extend telescopic dipper If fitted MOLI12LBB0092AA 24 2 25 ...

Page 101: ...3 CONTROLS AND INSTRUMENTS Setup menu LEIL12TLB00006I 1 3 39 ...

Page 144: ...3 CONTROLS AND INSTRUMENTS 3 82 ...

Page 164: ...4 OPERATING INSTRUCTIONS 4 20 ...

Page 166: ...5 TRANSPORT OPERATIONS RAIL14TLB1181GA 1 5 2 ...

Page 222: ...6 WORKING OPERATIONS 6 44 ...

Page 247: ...7 MAINTENANCE Fuel tank capacity 145 L 38 30 US gal 2WS 124 L 32 76 US gal 4WS 7 25 ...

Page 347: ...7 MAINTENANCE Fuses and relays Powershift cab 2WS MOLI12LBB0491CA 7 7 125 ...

Page 349: ...7 MAINTENANCE Fuses and relays Powershift cab 4WS MOLI12LBB0492CA 8 7 127 ...

Page 390: ...8 TROUBLESHOOTING 8 28 ...

Page 418: ...9 SPECIFICATIONS 4WS LEEN11T0039FA 2 9 28 ...

Page 420: ...9 SPECIFICATIONS 2WS 590ST LEEN11T0041FA 5 4WS 695ST LEEN11T0042FA 6 9 30 ...

Page 433: ......