INTRODUCTION

Hoses and tubes

Always replace hoses and tubes if the cone end or the

end connections on the hose are damaged.

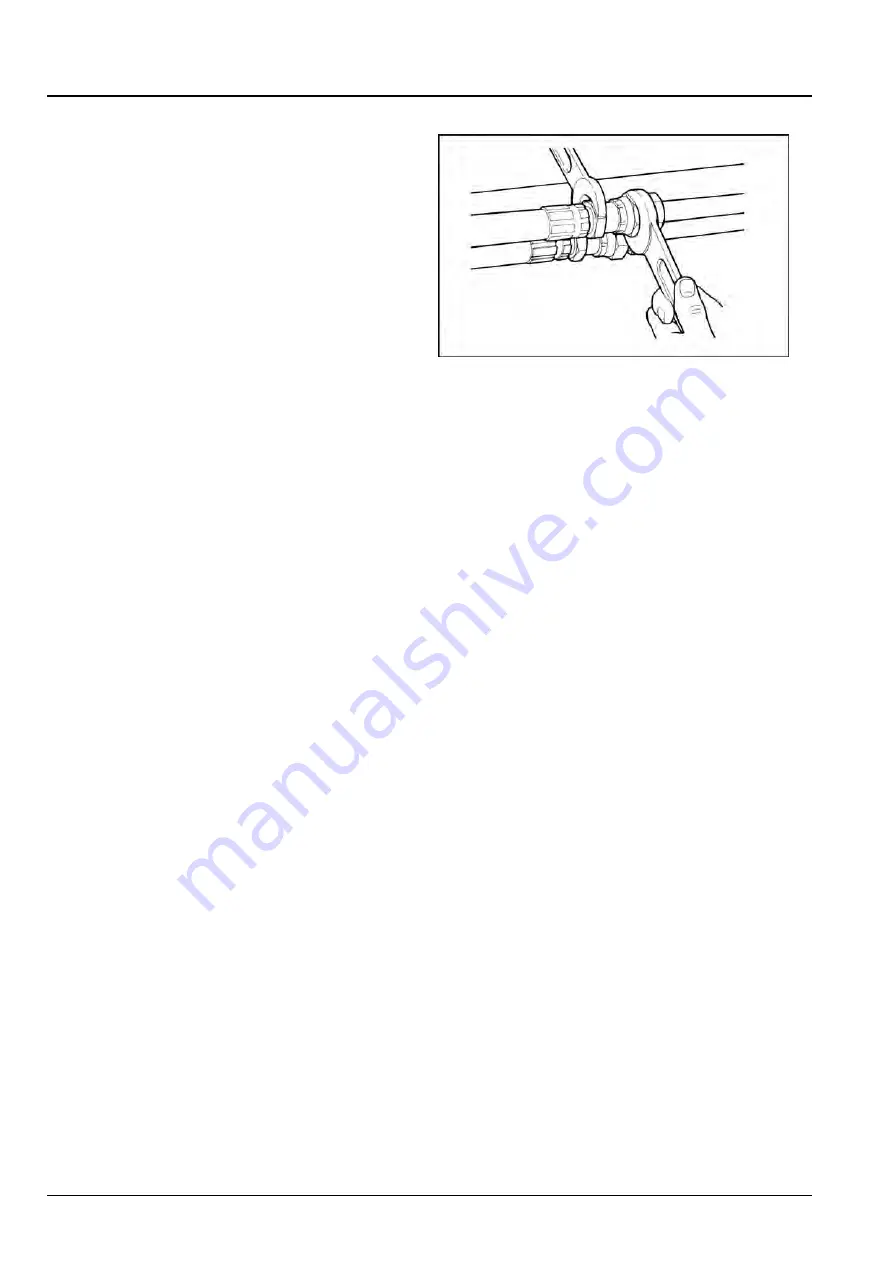

When installing a new hose, loosely connect each end

and make sure the hose takes up the correct position be-

fore tightening the connections. Clamps should be tight-

ened sufficiently to hold the hose without crushing and to

prevent chafing.

After hose replacement to a moving component, check

that the hose does not foul by moving the component

through the complete range of travel. Be sure any hose

which has been installed is not kinked or twisted.

Hose connections which are damaged, dented, crushed

or leaking, restrict oil flow and the productivity of the com-

ponents being served. Connectors which show signs of

movement from the original position have failed and will

ultimately separate completely.

A hose with a frayed outer sheath will allow water penetra-

tion. Concealed corrosion of the wire reinforcement could

subsequently occur along the hose length with resultant

hose failure.

Ballooning of the hose indicates an internal leakage due to

structural failure. This condition rapidly deteriorates and

total hose failure soon occurs.

Kinked, crushed, stretched or deformed hoses generally

suffer internal structural damage which can result in oil

restriction, a reduction in the speed of operation and ulti-

mate hose failure.

Free-moving, unsupported hoses must never be allowed

to touch each other or related working surfaces. This

causes chafing which reduces hose life.

TULI12WEX2014AA

10

O-rings

Replace O-rings, seal rings and gaskets whenever they

are disassembled.

Never mix new and old seals or O-rings, regardless of

condition. Always lubricate new seal rings and O-rings

with hydraulic oil before installation to relevant seats.

This will prevent the O-rings from rolling over and twisting

during mounting which will jeopardize sealing.

47881872_EN 24/06/2015

8