6 - MAINTENANCE

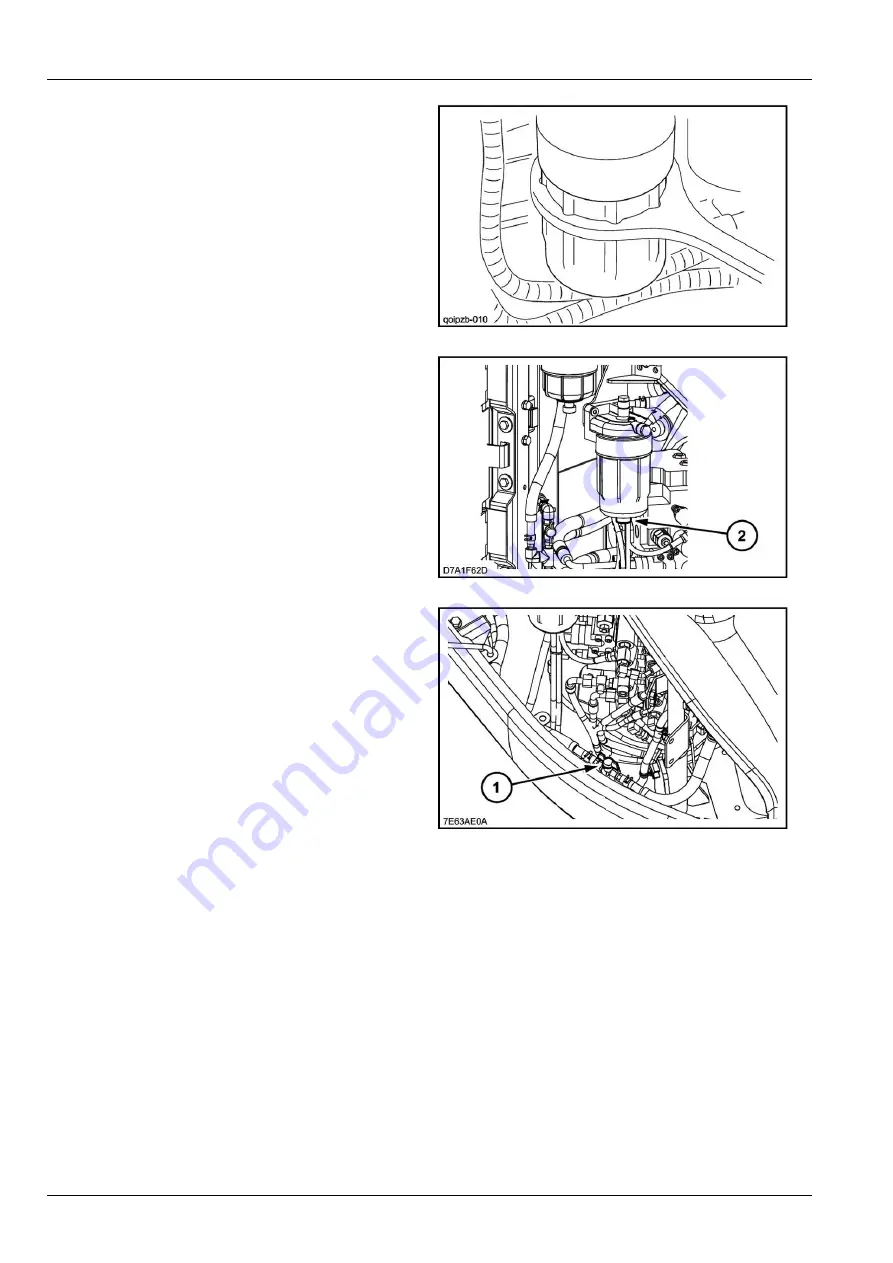

4. Clean around the pre-filter body then remove it using

the wrench provided with the machine.

5. Install the new filter element. Replace the filter body

seal, then install the body, turning it until it is in contact

with the pre-filter head.

ATTENTION:

Do not fill the filter body with fuel before

installing.

6. Tighten the body using the wrench, the tightening

torque must be from

28 - 32 N·m

(

20.7 - 23.6 lb ft

).

NOTE:

Bind tight within regulation torque.

QOIPZB-010

5

7. Replace the drain plug

(2)

seal then install the drain

plug

(2)

; the tightening torque must be between

8 - 12

N·m

(

5.9 - 8.9 lb ft

)

ATTENTION:

Overtightening can damage the seal.

ATTENTION:

Never re-use the seals of the filter body

or the drain plug

(2)

; they must always be replaced

with new seals.

NOTE:

Bind tight within regulation torque.

D7A1F62DA

6

8. Open the valve

(1)

on the supply line.

9. Bleed the system. See "Fuel system air bleed".

7E63AE0A

7

Replacing the fuel filter element

Replace the fuel filter element at the same time as pre-

filter element.

ATTENTION:

If a fuel filter other than a genuine CASE

CONSTRUCTION filter is used, the guarantee will not be

applied to a fault caused by the use of a wrong filter.

1. Place a receptacle of a suitable capacity under the fuel

filter.

6-32

Summary of Contents for CX145C SR

Page 6: ......

Page 18: ...1 GENERAL INFORMATION 1 12 ...

Page 29: ...2 SAFETY INFORMATION E5054225_TU 4 2 11 ...

Page 132: ...3 CONTROLS INSTRUMENTS 3 82 ...

Page 160: ...4 OPERATING INSTRUCTIONS 4 Operate the arm control to unhook the tool KKZVLU 024A 14 4 28 ...

Page 180: ...4 OPERATING INSTRUCTIONS 4 48 ...

Page 206: ...6 MAINTENANCE Offset boom pin 10 07C803C9 17 6 16 ...

Page 207: ...6 MAINTENANCE Arm backhoe bucket 375EFD72 18 AB1F527A 19 6 17 ...

Page 298: ...8 SPECIFICATIONS Offset maximum left EACB5F36 6 See next page for the value 8 14 ...

Page 300: ...8 SPECIFICATIONS 8 16 ...