6 - MAINTENANCE

Cooling system

CAUTION

Burn hazard!

Take care if removing the filler cap while the system is hot. Before removing the cap: completely cover

the cap using a thick cloth, and slowly open the filler cap to allow the pressure to escape. Do not add

cold water to a hot coolant reservoir.

Failure to comply could result in minor or moderate injury.

C0031A

WARNING

Hazardous chemicals!

Coolant can be toxic. Avoid contact with skin, eyes, and clothing. Antidotes:

EXTERNAL - Rinse thoroughly with water. Remove soiled clothing.

INTERNAL - Rinse the mouth with water. DO NOT induce vomiting. Seek immediate medical attention.

EYES - Flush with water. Seek immediate medical attention.

Failure to comply could result in death or serious injury.

W0282A

Service specifications

Expansion reservoir level check: Every 10 hours or every day

Checking the tightening of clamps, of radiator hoses: Every 250 hours or every 6 months

Draining the system (long duration): Every 1000 hours or every 2 years

Draining the system (with anti-freeze) (spring and autumn): Twice a year

System capacity:

15.3 l

(

4.0 US gal

)

Type of coolant: (Refer to page

6-5

)

NOTICE:

Check and service the cooling system according to the instructions given in this manual.

Coolant solution

Put only ethylene-glycol coolant solution in the cooling system. Use good quality ethylene-glycol that has a high

boiling point, with no additives to prevent leakage. Do not use non-approved anti-rust additives. Anti-rust additives

and ethylene-glycol can mix and work against each other, thereby reducing anti-corrosion protection, forming deposits

in the cooling system and causing damage to the cooling system and radiator.

Consult your CASE CONSTRUCTION Dealer who will supply you with the suitable coolant.

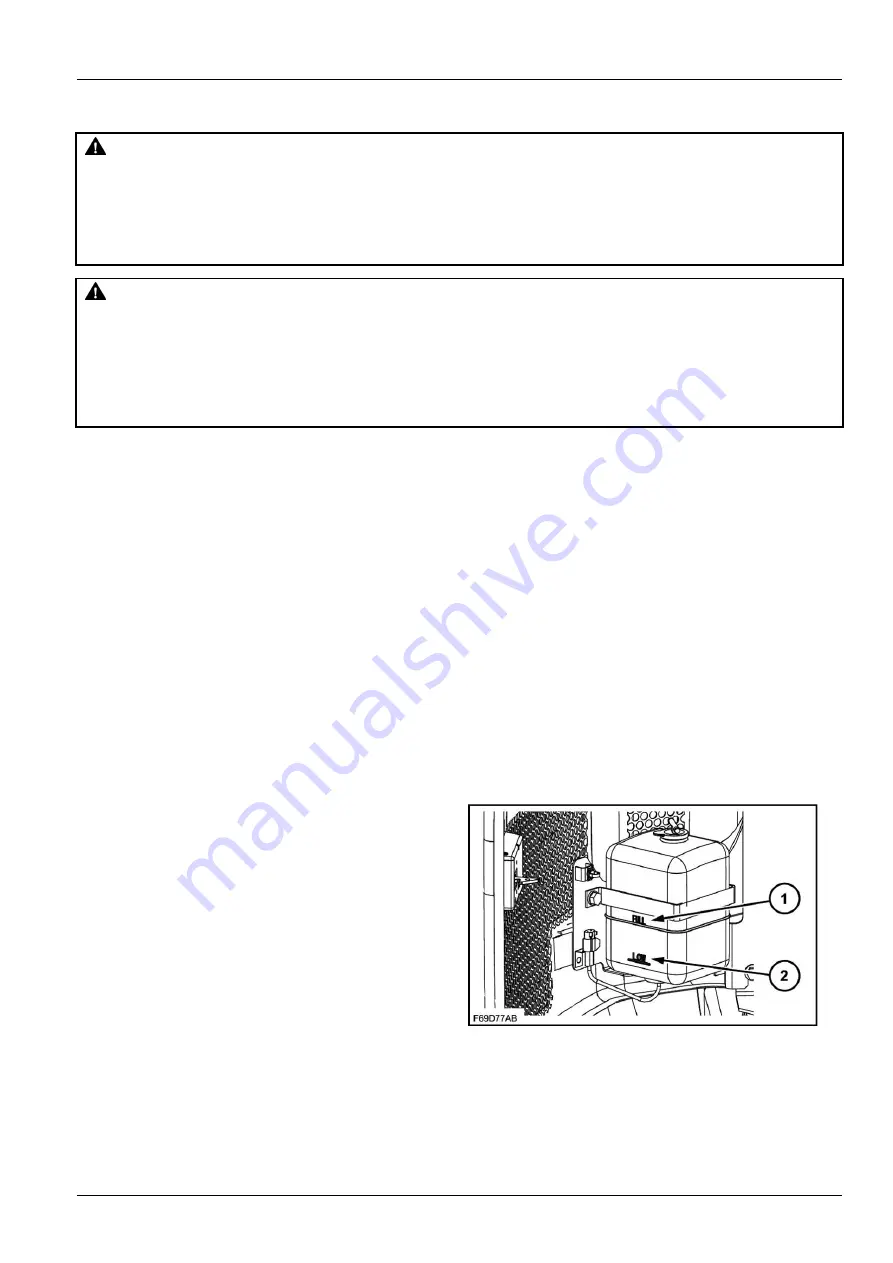

Level

The level of coolant solution should be checked when the

engine is cold.

On flat, level ground, before using the machine (while the

engine is still cold), the level in the expansion reservoir

should be between the

“Full” (1)

and

“Low” (2)

marks.

If not, see "Filling".

F69D77AB

1

6-27

Summary of Contents for CX145C SR

Page 6: ......

Page 18: ...1 GENERAL INFORMATION 1 12 ...

Page 29: ...2 SAFETY INFORMATION E5054225_TU 4 2 11 ...

Page 132: ...3 CONTROLS INSTRUMENTS 3 82 ...

Page 160: ...4 OPERATING INSTRUCTIONS 4 Operate the arm control to unhook the tool KKZVLU 024A 14 4 28 ...

Page 180: ...4 OPERATING INSTRUCTIONS 4 48 ...

Page 206: ...6 MAINTENANCE Offset boom pin 10 07C803C9 17 6 16 ...

Page 207: ...6 MAINTENANCE Arm backhoe bucket 375EFD72 18 AB1F527A 19 6 17 ...

Page 298: ...8 SPECIFICATIONS Offset maximum left EACB5F36 6 See next page for the value 8 14 ...

Page 300: ...8 SPECIFICATIONS 8 16 ...