6 - MAINTENANCE

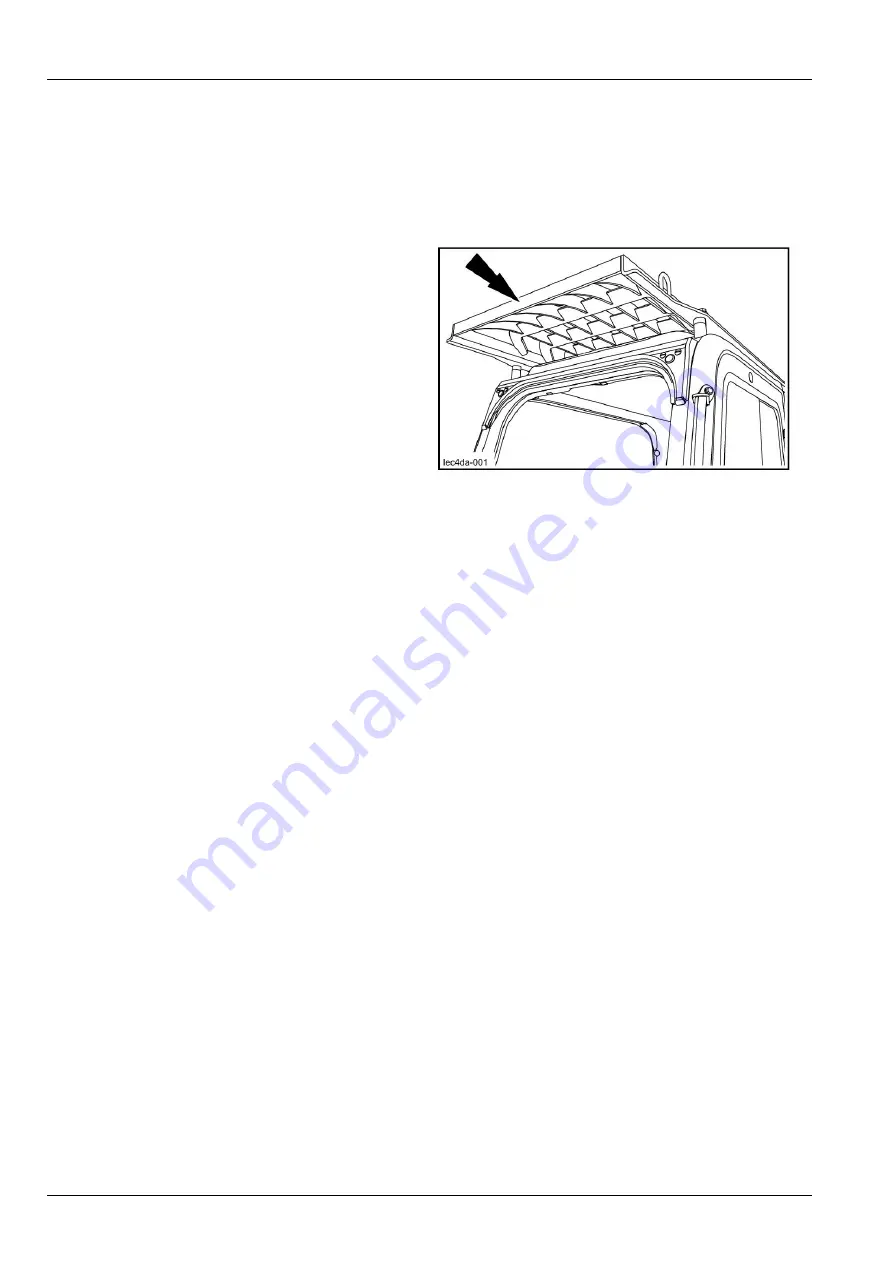

Cab protection (ROPS and FOPS) (optional)

Service specifications

Check: Every 250 hours (after the first 50 hours during the run-in period)

Maintenance and checks

Check the retaining hardware, if necessary retighten the

screws.

Check the absence of cracks, rust or holes in the pro-

tective structure and the components that constitute it.

Ageing, bad weather and accidents can cause damage.

If you have even the slightest doubt regarding the con-

dition of the structure, consult your CASE CONSTRUC-

TION Dealer.

If the protective structure has suffered any accident, it

is necessary to replace the damaged components of the

structure in order to restore the initial protection, consult

your CASE CONSTRUCTION Dealer.

LEC4DA-001A

1

Machine inspection and cleaning

Service inspections

Inspect and clean: Periodically

Or whenever oil or grease has been spilt on the machine.

Do not use compressed air if there is oil or soot in the element.

Take the opportunity during this operation to make a visual check of all the welded components (in case of appearance

of cracks), the attachment linkages and check the teeth and tooth tips for correct retention and for wear. Look for any

leaks and check the condition of all pipes and hoses.

Checking the machine settings

Service specifications

Have this checked by your CASE CONSTRUCTION Dealer: Every 6 months

6-60

Summary of Contents for CX300C

Page 6: ......

Page 18: ...1 GENERAL INFORMATION 1 12...

Page 28: ...2 SAFETY INFORMATION QNTTT2 011B_TU 3 2 10...

Page 50: ...2 SAFETY INFORMATION 2 32...

Page 130: ...3 CONTROLS INSTRUMENTS 3 80...

Page 157: ...4 OPERATING INSTRUCTIONS 4 Operate the arm control to unhook the tool KKZVLU 024A 14 4 27...

Page 172: ...4 OPERATING INSTRUCTIONS 4 42...

Page 182: ...5 TRANSPORT OPERATIONS 5 10...

Page 272: ...6 MAINTENANCE 6 90...

Page 280: ...8 SPECIFICATIONS Working range 4M8ORU 002A 2 See next page for the values 8 6...

Page 282: ...8 SPECIFICATIONS 8 8...