INTRODUCTION

Size

Nm

lb in/lb ft

5/8-11 in

190 - 203 Nm

140 - 150 lb ft

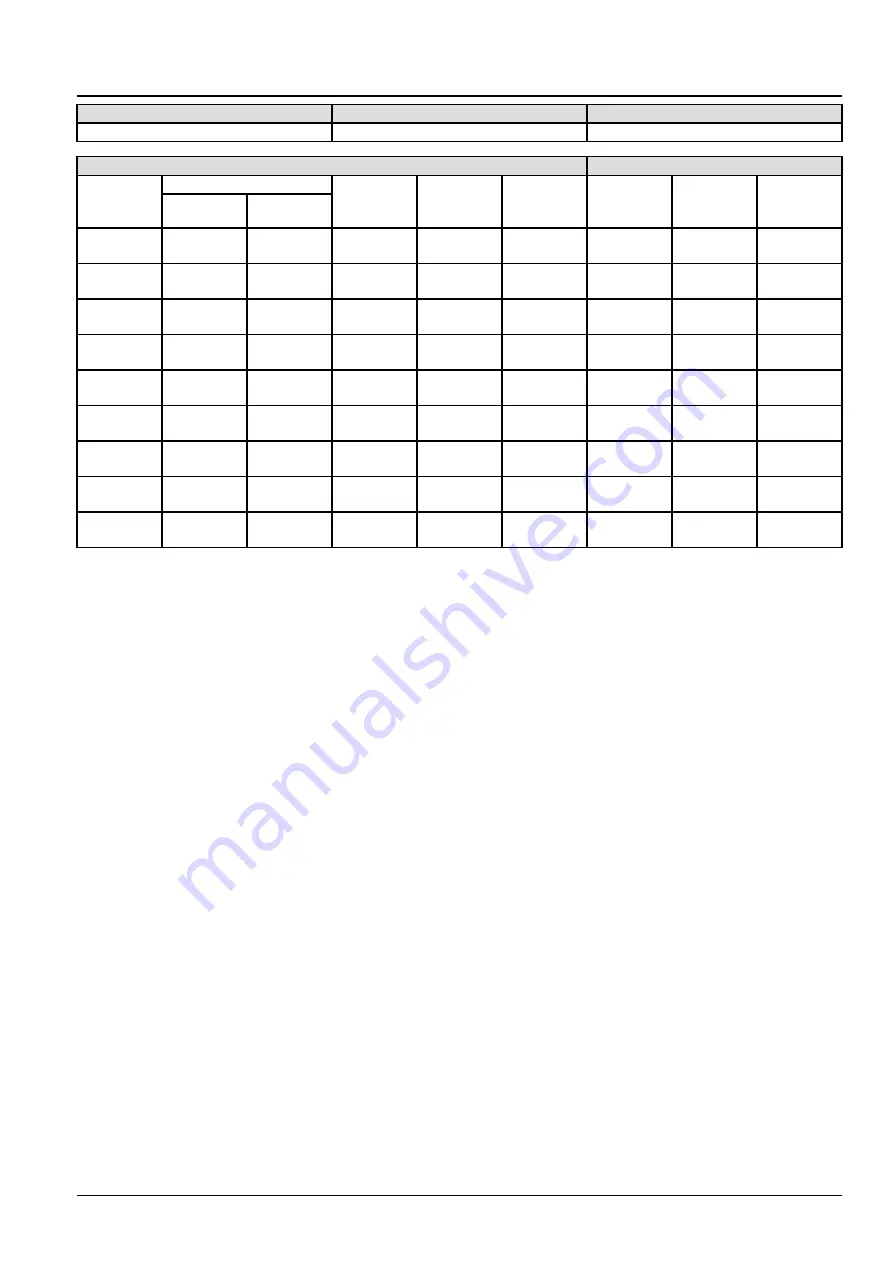

O-ring face seal end

O-ring boss end fitting or lock nut

Tube outside diameter

Nominal

SAE dash

size

mm

in

Thread size Nm

lb in/lb ft

Thread size Nm

lb in/lb ft

-4

6.4 mm

1/4 in

9/16-18 in

14 - 16 Nm 120 - 144 lb

in

7/16-20 in

23 - 27 Nm 204 - 240 lb

in

-6

9.5 mm

3/8 in

11/16-16 in 24 - 27 Nm 216 - 240 lb

in

9/16-18 in

34 - 41 Nm 300 - 360 lb

in

-8

12.7 mm

1/2 in

13/16-16 in 43 - 54 Nm 384 - 480 lb

in

3/4-16 in

61 - 68 Nm 540 - 600 lb

in

-10

15.9 mm

5/8 in

1-14 in

62 - 76 Nm 552 - 672 lb

in

7/8-14 in

81 - 88 Nm 60 - 65 lb ft

-12

19.0 mm

3/4 in

1-3/

16-12 in

90 -

110 Nm

65 - 80 lb ft 1-1/

16-12 in

115 -

122 Nm

85 - 90 lb ft

-14

22.2 mm

7/8 in

1-3/

16-12 in

90 -

110 Nm

65 - 80 lb ft 1-13/

16-12 in

129 -

136 Nm

95 - 100 lb

ft

-16

25.41 mm

1.0 in

1-7/

16-12 in

125 -

140 Nm

92 - 105 lb

ft

1-5/

16-12 in

156 -

169 Nm

115 - 125 lb

ft

-20

31.8 mm

1-1/4 in

1-11/

16-12 in

170 -

190 Nm

125 - 140 lb

ft

1`-5/

6-12 in

201 -

217 Nm

150 - 160 lb

ft

-24

38.1 mm

1-1/2 in

2-12 in

200 -

254 Nm

150 - 180 lb

ft

1-7/8-12 in 258 -

271 Nm

190 - 200 lb

ft

S5PX0011E01 14/10/2014

11