IOM-764P / PD

2

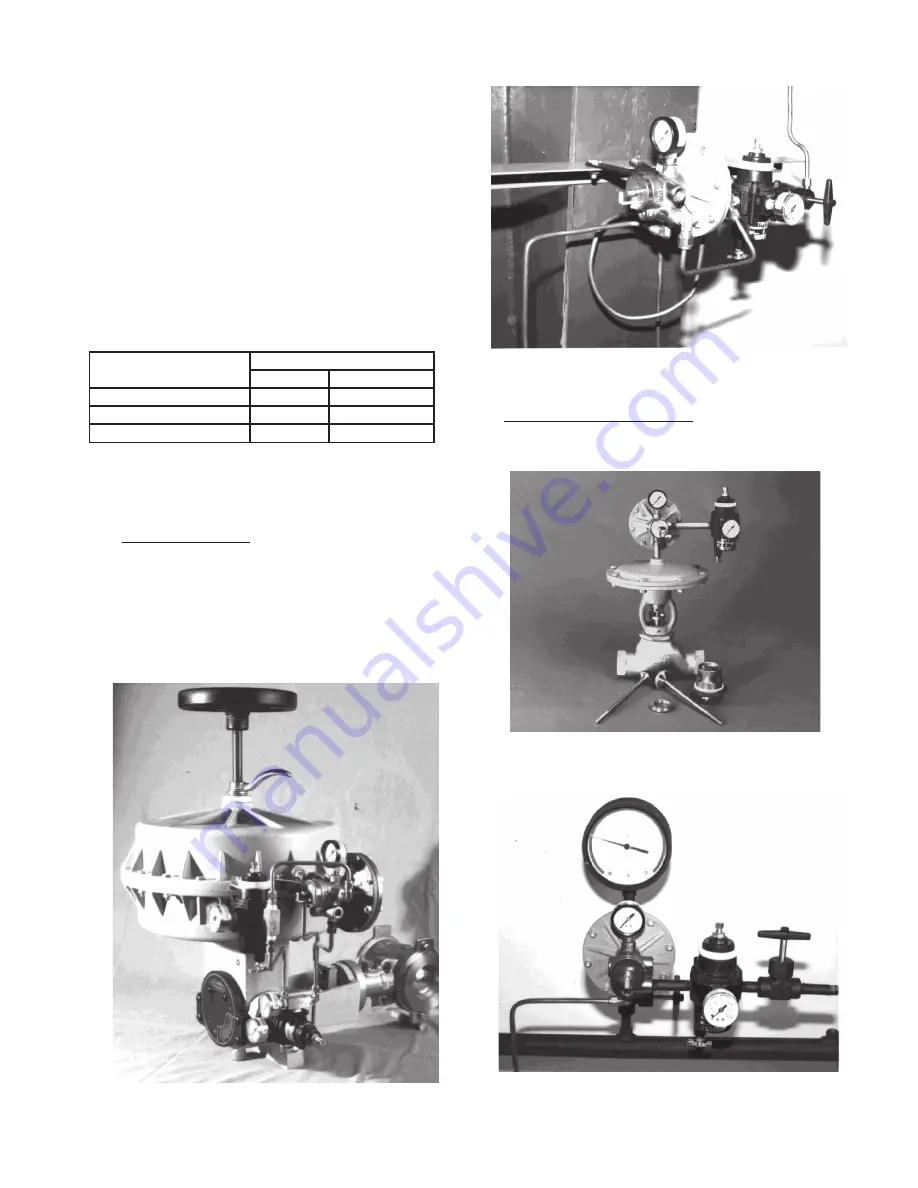

Figure 3

With Option -23; Field Bracket Mounting to Structure

Field Pipe Nipple Mounted

. Recommend pipe tap

on top or side of pipe.

Figure 4

Output Pipe Nipple Mounted to Model 2266 Control Valve

Figure 5

Field Pipe Nipple Mounted to Piping

6. It is recommended as a good practice to locate

the controller as close as practical to the pressure

tapping and at a similar elevation. For installations

where the controller was factory mounted on a

control valve unit, the pressure tapping should

be within 6 - 10 feet (2 - 3 meters) of the control

valve. (Remember to compensate for tappings

located above the elevation of the controller for

any liquid pressure head that may occur.)

7. The controller’s pneumatic output signal (SIG)

piping or tubing should be limited in length, and

con sid er ation must be given for the ultimate

pur pose of the SIG at its final destination. The

fol low ing are recommended practices:

8. 764P controllers may be mounted by various

meth ods:

Bracket Mounted

. Includes a bracket with

ma chine screws to allow attachment to a fixed

struc tur al ap pend age; requires specifying Option

-23. (This is the method utilized when the 764P/

PD is spec i fied to be mounted to a control valve

ac tu a tor.)

Figure 2

Factory Bracket Mounted to Ranger QCT Control Valve

Purpose

Tubing

Size

Max Length*

SIG to Positioner

1/4" O.D.

100 ft.

SIG to Supply Booster 1/4" O.D.

100 ft.

LOAD to Actuator

1/4" O.D.

10 - 12 ft.

* Contact factory for longer lengths.