IOM-Ranger

10

4. For Non-Live-Loaded Packing Con struc tion:

a. Remove two packing flange stud nuts

(22) and two cap screws (19) on the 1",

1-1/2" and 2" sizes, or four nuts (22) on the

3", 4", 6" and 8" sizes.

b. Pull yoke (12), packing flange (14), pack ing

follower (15) and follower bushing strip (16) off

over end of stem (7). Re place packing follower

(15) if sig nif i cant ly cor rod ed. Always replace

fol low er bushing strip (16) when of standard

construction.

c. Proceed with previous steps 3.j. through 3.q.

for stem removal.

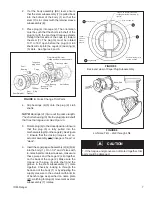

E. Stem Reassembly – Trim Retained in Body:

1. Slide retainer sleeve subassembly (8) onto

the stem subassembly (7), with the car bon

bushing (8.2) end against the shoul der of the

stem subassembly (7).

NOTE:

For Slurry Trim see Subsection H.

2. Insert the stem/retainer sleeve (7)(8) as sem bly

into the body (1), aligning the hole in the retainer

sleeve (8) to be directly in line with the thread ed

hole in the body (1) bonnet. Align the stem

sub as sem bly (7) so that the plug’s (6) tongue

and the stem's (7) groove will engage.

NOTE:

A small "flat" area has been milled on the

stem and for correct engagement this "flat" must

be on the same side as the face of the plug (6).

3. Visually confirm alignment of hole in re tain er

sleeve (8.1) with threaded hole in body

(1) bonnet. Place thread sealant Cotronic

Resbond 907, or equal, on stem retainer screw

(17) threads for valves

used in non-oxygen

service;

thread sealant to be Oc ci den tal

Petroleum Corp. Fluorolube GR-362, or

equal, for valves

used in oxygen service.

Insert and tight en stem re tain er screw (17)

20-25 ft# (27-34 N-M) for 1"– 2" sizes,

80-85 ft# (108-115 N-M) for 3"– 8LF" sizes

and 90 ft# (122 N-M) for 8"HF size.

4. Rotate stem (7) to ensure tongue and groove

engagement with plug (6).

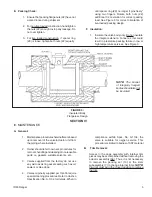

m. Using a suitable solvent acceptable to the owner,

thoroughly clean the valve stem (7) and the

body's (1) stuffing box. Inspect surface finish of

stem sub as sem bly (7) and internal wall finish of

packing box bore at packing (13) area. If deeply

scratched, corroded or pit ted, re place with new

parts.

n. It will be desirable to restore the surface of

the body's (1) stuffing box to 16 mi cro-inch Ra

finish; metal removal should not exceed 0.001

inch ma te ri al.

o. It will be desirable to restore the sur face of the

stem's (7) critical area to 6–8 micro-inch Ra

finish or better, metal re mov al should not exceed

0.001 inch ma te ri al. Minimum stem OD should

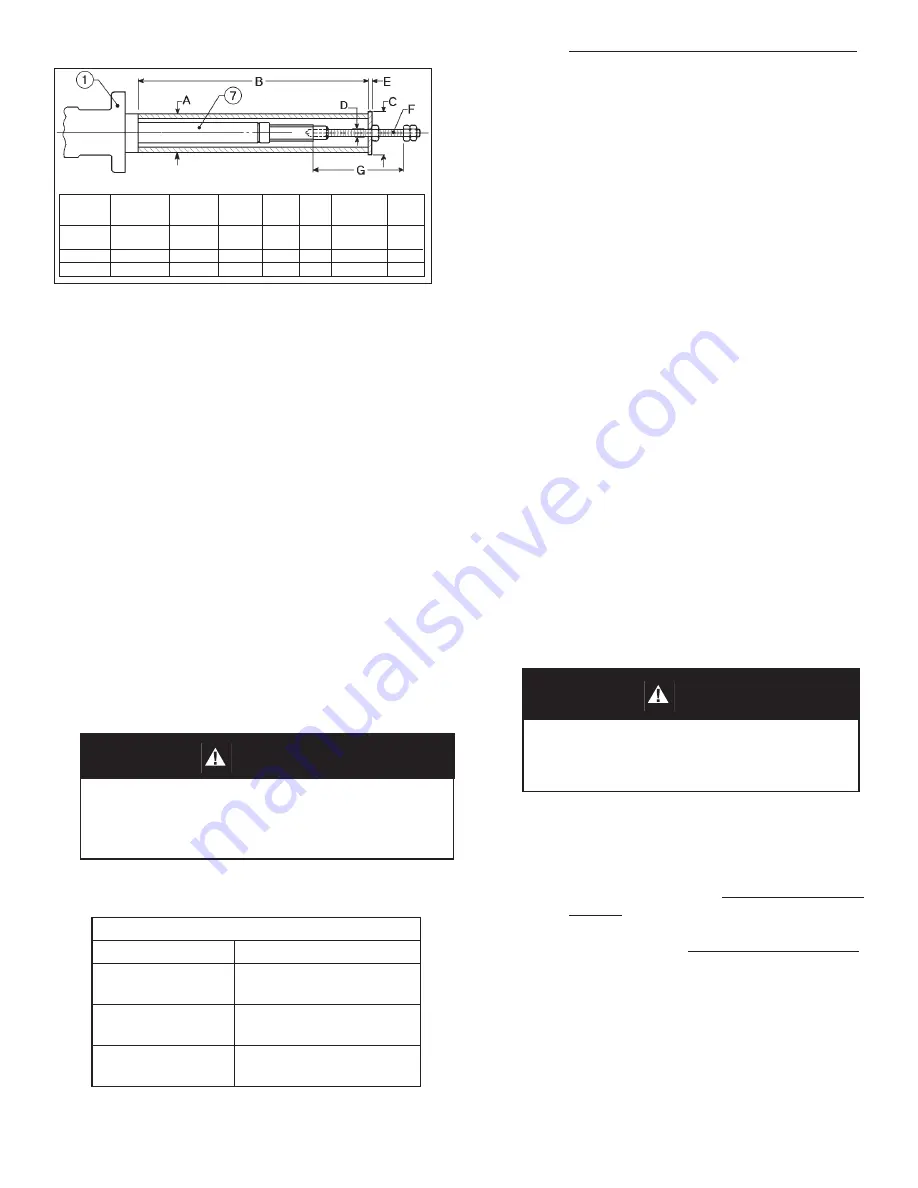

not be less than indicated in Table 4.

p. Remove retainer sleeve sub as sem bly (8) from

stem subassembly (7). Ex am ine carbon bushing

insert of re tain er sleeve subassembly (8) for

dam age or signs of wear. Replace re tain er

sleeve sub as sem bly (8) if worn more than 0.005

inch (0.13 mm). See Figure 12 for indicated

di men sion “X”.

q. Examine packing studs (21) and nuts (22).

Replace if signs of corrosion are present.

TABLE 4 - STEM O.D.

Body Size

Minimum Stem O.D.

1", 1-1/2" & 2"

(DN25, 40 & 50)

.620

3" & 4"

(DN80, 100)

.995

6" & 8"

(DN150, 200)

.995

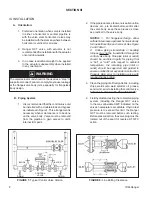

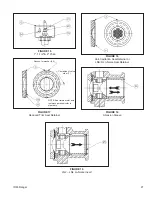

DIMENSIONS

Valve

A

B

C

D

E

F

G

Size

(Pipe Size)

(O.D.) (I.D.)

(Thd Rod)

1", 1-1/2,"

3/4"

7-13/16" 1-1/4" 5/16" 3/16" 1/4"-28

4"

2"

3",

4"

1-1/2" 11-13/16" 2-1/8" 7/16" 1/4" 3/8"-24 4-1/2"

6",

8" 2-1/2" 9-3/16" 3-1/8" 7/16" 1/4" 3/8"-24 4-1/2"

FIGURE 10:

Stem Puller

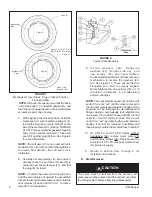

CAUTION

Do not hammer on end of stem. Potential exists to

cause damage to the tongue and groove connection

or to the seals.

CAUTION

The tongue and groove connection between the stem

subassembly (7) and the plug (6) can cause me chan i cal

damage or disengagement if the carbon bushing in sert

is worn.