IOM-Ranger

17

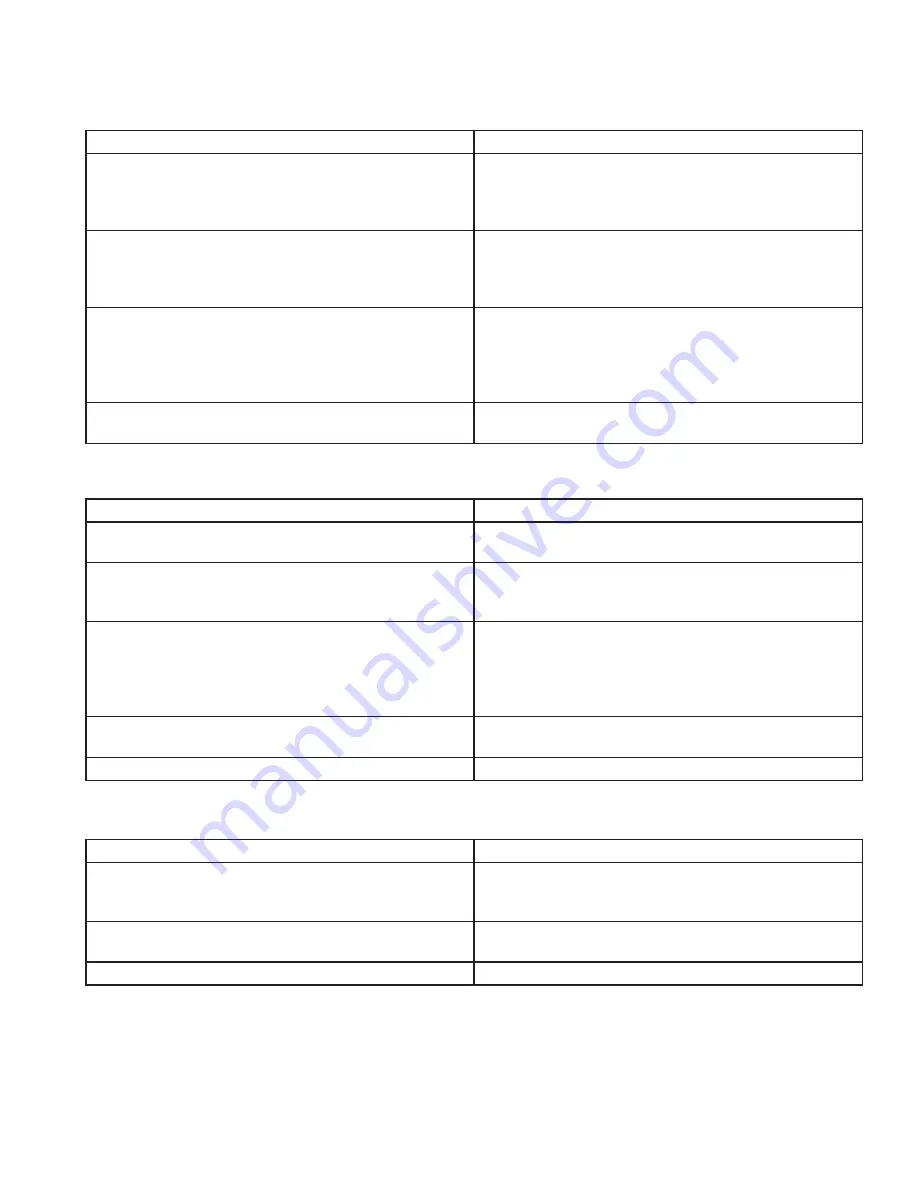

4. Premature Packing Leakage.

Possible Cause

Remedy

A.

Over-temperature.

A1.

Remove insulation along body to allow direct

contact with ambient air.

A2.

Replace standard packing with high-temp.

packing - re quires positioner.

B.

Improper packing orientation.

B1.

Ensure correct stack up of packing pieces.

B2.

Determine if packing is being exposed to a

vacuum at any time. Consult factory if vacuum

is

occurring.

C.

Insufficient force/packing follower loose.

C1.

Tighten packing follower/nuts to indicated

dimension per Section 8. Replace with new

packing assembly as necessary.

C2.

Replace packing spring washers if corrosion is

obvious.

D.

New valve installed at operating pressures

and

temperatures.

D.

Adjust per Section III, Subsection E.

5. Seal Retainer/Flange Leakage

Possible Cause

Remedy

A.

Improper pipe supports and anchors.

A.

Provide piping anchors and guides at control

valve station. Restrain bending movements.

B.

Incorrect line bolting.

B.

Use high strength line bolting heat treated alloy

steel (Opt-7A) or corrosion resistant SST

strainer

hard

ened studs (Opt-7C).

C.

Flange bolting unevenly loaded.

C1.

Loosen and remove line bolting, replace flange

gasket and reinstall flange bolting. See Table

3, Section III, for line bolting torques.

C2.

Valve used to “pull” pipe into alignment. Loosen

bolting, properly align pipe and retighten bolting.

D.

Incorrect seal retainer gasket material.

D.

Remove seal retainer gaskets and replace with

factory supplied flexitallic gaskets.

E. Corrosion

E. Consult

factory.

6. Insuf

fi

cient Capacity.

Possible Cause

Remedy

A.

Wrong valve size.

A.

Recheck original sizing conditions with actual

calculated Cv and install new trim pieces or

complete valve as necessary.

B.

Seal retainer too small.

B.

Change seal retainer size in accordance to Cv

calculations.

C.

Improper actuator bench setting.

C.

Calibrate actuator to valve for 90° travel.