IOM-Ranger

4

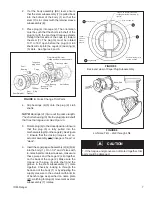

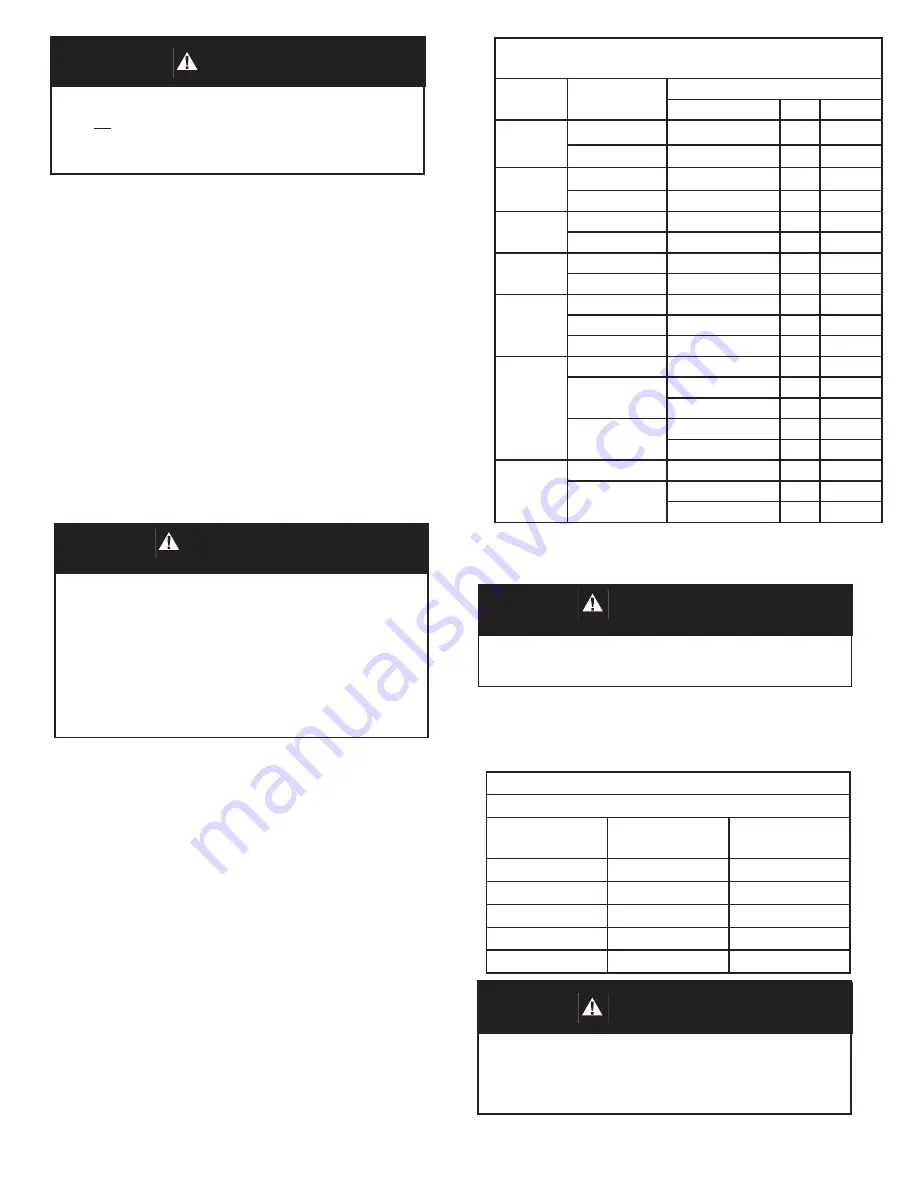

CAUTION

Do not torque line bolting beyond the limitations of

Table 3. Ref er ence the “Ranger-TB” for tem per a ture

range of Opt-7A alloy steel and Opt-7C SST line bolting.

TABLE 2

Recommended Line Bolting Dimensions

Valve Size

Line Flange

ANSI Class

Tie Rod Studs

Dia.-Thd. UNC

Qty.

Length

1"

150

1/2"-13

4

7.75"

300-600

5/8"-11

4

8.00"

1-1/2"

150

1/2"-13

4

7.75"

300-600

3/4"-10

4

9.00"

2"

150

5/8"-11

4

9.25"

300-600

5/8"-11

8

9.25"

3"

150

5/8"-11

4

10.50"

300-600

3/4"-10

8

12.25"

4"

150

5/8"-11

8

11.50"

300

3/4"-10

8

12.25"

600

7/8"-9

8

14.25"

6"

150

3/4"-10

8

13.75"

300

3/4"-10

10

14.75"

3/4"-10

4

5.50

600

1"-8

10

16.50"

1"-8

4

6.75"

8"

150

3/4"-10

8

15.50"

300

7/8"-9

10

16.50"

7/8"-9

4

6.25"

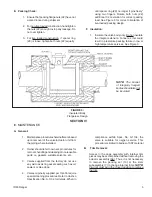

3. Line Bolting Material must comply with ANSI B16.34

and be compatible with the in tend ed service.

4. Tighten the line bolting evenly and in small

in cre ments to avoid uneven load ing of the seal

retainer (3) and seal retainer gas ket (9). See Ta ble

3 for minimum and max i mum line bolt ing torques.

CAUTION

Do not allow the body to “cock” between the flanges.

Valve must be centered on the flanges.

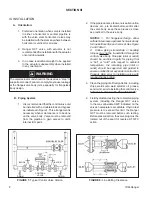

D. Body Installation:

The Ranger QCT body can be installed be tween

ANSI Class 150, 300 or 600 lb. RF or FF flanges

or their ISO equivalent of PN20, 50 or 100. Socket

weld, weld neck or slip on companion flanges

can be used. Face-to-face di men sions are per

ISA 75.08.02.

1. Install valve so the flow direction matches the

arrow on the valve body.

2. For flangeless design alignment, special

boss es cast on the valve body contact the line

bolting and help center the valve in the pipe line.

See Table 2 for Line Bolting Di men sions.

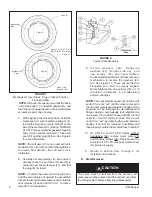

CAUTION

DO NOT USE THE RANGER BODY ASSEMBLY AND

LINE BOLTING TO PULL FLANGE PIPE ENDS INTO

ALIGNMENT. Seal retainer may shift, dam ag ing the seal

retainer gasket allowing leakage between body and seal

retainer. Movement of seal retainer may compromise the

valve's ability to meet stated shut-off leakage rates. Could

also allow leak age between body and flange pipe ends.

WARNING

Do not adjust temporary air supply pressure after cover

plate (20) has been removed. Valve contains parts which

could move during maintenance exposing hand and/or

fingers to a hazardous condition.

TABLE 3

Line Bolting Torques for Flangeless Bodies

Stud Size &

Thread UNC

Max. Torque

Ft-Lb.

Min. Torque

Ft-Lb.

1/2"-13

65

60

5/8"-11

120

100

3/4"-10

200

140

7/8"-9

320

160

1"-8

440

180